When your production line grinds to a halt because of supplier quality issues, the real cost extends far beyond delayed shipments. A single batch of non-compliant flexible circuits can trigger product recalls, damage your brand reputation, and jeopardize relationships with your customers. For engineering teams and procurement specialists managing high-volume flexible PCB production, the difference between a reliable manufacturing partner and a problematic supplier often comes down to certification gaps you didn’t know to look for.

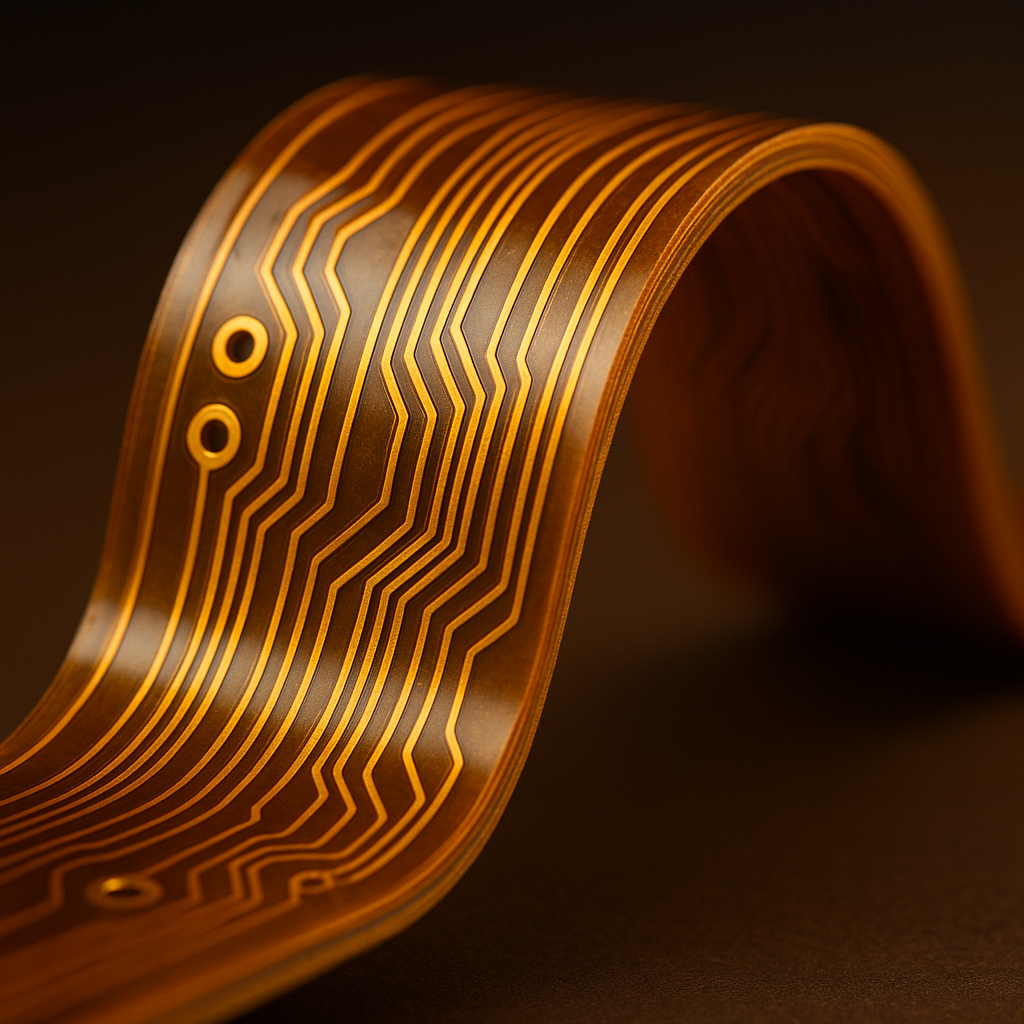

The flexible PCB industry has evolved dramatically over the past two decades. What once served niche applications now powers everything from electric vehicles to medical implants, from aerospace systems to wearable devices. Yet many companies still approach supplier evaluation with outdated checklists, missing critical certification requirements that only become apparent when quality issues emerge downstream.

Understanding the Supplier Qualification Framework

Choosing a flexible PCB supplier isn’t simply about comparing quotes and lead times. It requires a systematic evaluation framework that examines governance structures, technical capabilities, quality management systems, and process controls. At the foundation of this framework lies a fundamental question: Does this supplier have the organizational maturity and certified processes to scale from prototypes to mass production while maintaining consistent quality?

The most reliable suppliers operate with full end-to-end manufacturing control. When you work directly with a manufacturer rather than through brokers or trading companies, you gain direct communication with production engineers, eliminate middleman delays, and ensure quality consistency across every production run. This direct relationship becomes especially critical when dealing with complex rigid-flex designs or specialized applications requiring medical-grade or automotive-certified materials.

Compliance and traceability form the backbone of supply chain integrity in regulated industries. A supplier’s quality management system must provide complete material traceability from raw substrates through final inspection. For medical device manufacturers requiring ISO 13485 compliance or automotive suppliers needing IATF 16949 certification, this traceability isn’t optional—it’s a regulatory requirement that protects both your company and your end customers.

Consider how FlexPlus approaches this challenge. With over 20 years of specialized experience and certifications spanning ISO 9001, ISO 13485, IATF 16949, and ISO 14001, the company maintains systematic documentation throughout every manufacturing stage. This isn’t simply about passing audits—it’s about building manufacturing processes that consistently produce reliable flexible circuits for mission-critical applications.

Design-for-Manufacturability: Where Theory Meets Production Reality

The gap between a functional PCB design and a manufacturable one often determines whether your product launches on schedule or faces costly delays. Design-for-manufacturability considerations become exponentially more important with flexible circuits due to their unique mechanical and electrical properties.

Bend radii represent one of the most critical yet frequently overlooked design parameters. When a flexible circuit bends beyond its minimum radius, internal stresses can crack copper traces, separate layers, or compromise PTH reliability. A qualified supplier doesn’t simply manufacture to your specifications—they provide engineering feedback during the design phase to identify potential failure points before production begins.

Trace routing on flexible substrates requires different considerations than rigid PCBs. Traces positioned perpendicular to bend lines experience less stress than parallel traces. Staggering traces across multiple layers in a rigid-flex stack-up distributes mechanical stress more evenly. These design principles sound straightforward, but implementing them requires deep manufacturing expertise and direct collaboration between your engineering team and the supplier’s production engineers.

PTH interactions with flexible materials create another common failure mode. Plated through-holes act as stress concentrators when the substrate flexes, particularly in dynamic applications experiencing repeated bending cycles. A supplier with comprehensive DFM capabilities performs DFMEA analysis to identify these risks early, recommending design modifications like via placement optimization or copper weight adjustments to improve long-term reliability.

Real-world example: A wearable device manufacturer submitted a flexible circuit design with PTHs positioned directly in a high-flex zone. Rather than simply manufacturing to specification, the engineering team at FlexPlus conducted a flex simulation and recommended relocating the vias to a supported area with stiffener reinforcement. This design modification, implemented before prototype production, eliminated what would have become a field failure affecting thousands of units.

Materials and Construction: The Foundation of Reliability

Material selection determines whether your flexible circuit survives its intended operating environment or fails prematurely. The choice between polyimide and FR-4 substrates, adhesive versus adhesiveless constructions, and stiffener integration approaches all significantly impact manufacturability, reliability, and cost.

Polyimide substrates offer superior thermal stability, chemical resistance, and mechanical flexibility compared to FR-4, making them the preferred choice for dynamic flexing applications. However, polyimide’s hygroscopic nature means moisture absorption can lead to blistering during assembly if not properly controlled. Qualified suppliers maintain humidity-controlled storage and implement baking procedures before lamination to prevent moisture-related defects.

Adhesive systems present another critical consideration. Traditional acrylic adhesives provide good bonding strength but limit the circuit’s temperature range and may outgas during assembly. Adhesiveless constructions eliminate these concerns but require more sophisticated manufacturing processes and tighter process controls. A supplier’s material expertise should guide your selection based on your specific application requirements—whether that’s surviving automotive temperature cycles, maintaining biocompatibility for medical implants, or supporting the thermal demands of high-power LED systems.

Material compliance with RoHS and REACH standards isn’t optional in today’s global marketplace. Beyond basic compliance, qualified suppliers provide complete material declarations and maintain relationships with certified material suppliers who can document the entire supply chain. For companies serving European markets or aerospace/defense contractors with stringent material restrictions, this documentation provides essential protection against regulatory non-compliance.

FlexPlus’s approach to material innovation exemplifies this expertise. Their breakthrough TPU circuit technology enables circuits on medical-grade thermoplastic polyurethane substrates, opening new possibilities for wearable devices and beauty tech applications. The company’s proprietary flexible heat dissipation flow channels represent another material science advancement, addressing thermal management challenges in high-power applications through specialized material constructions that traditional flex PCB designs cannot achieve.

Standards and Testing: The Quality Assurance Foundation

Industry standards provide the common language and benchmarks that enable consistent quality across the flexible circuit supply chain. Understanding which standards apply to your application—and verifying your supplier’s compliance—separates qualified manufacturers from those simply claiming capability.

IPC-6013 establishes qualification and performance requirements for flexible printed circuits, defining three classes based on inspection levels and performance requirements. Class 1 serves general electronic products where appearance matters more than performance. Class 2 covers dedicated service electronic products where high reliability and extended life are required. Class 3 applies to products where continued performance and reliability are critical, including medical devices, aerospace systems, and mission-critical military equipment.

Your application determines which class applies, but here’s the crucial point: not all suppliers can consistently manufacture to Class 3 requirements. Process capabilities that work fine for consumer electronics may prove inadequate for medical implants requiring ISO 13485 compliance and Class 3 workmanship standards. Verifying a supplier’s actual manufacturing class capability—not just their claims—requires examining their certifications, inspection procedures, and quality metrics.

IPC-2223 provides design guidelines specifically for flexible and rigid-flex circuits, covering everything from bend radius calculations to structural specifications and conductor spacing. Meanwhile, IPC-TM-650 Method 2.4.3 defines testing procedures for flexural endurance—essentially how many bending cycles a flexible circuit can withstand before failure. For dynamic applications in aerospace, automotive, or wearable devices, flexural endurance testing represents the critical validation that your design will survive real-world operating conditions.

Testing requirements extend beyond basic electrical continuity. Qualified suppliers implement comprehensive testing protocols including microsectioning to verify PTH quality, thermal cycling to validate material systems, and flex testing to confirm bend life performance. For rigid-flex designs, the testing complexity increases significantly as the supplier must verify both the rigid sections’ structural integrity and the flexible sections’ dynamic performance.

The Supplier Qualification Process: Beyond Checklist Compliance

Effective supplier qualification requires moving beyond checkbox audits to evaluate actual manufacturing capabilities and performance consistency. This process typically unfolds across three phases: documentation review, on-site assessment, and pilot production validation.

The documentation phase examines certifications, process flow diagrams, quality manuals, and statistical process control data. Red flags include: expired certifications, generic quality manuals that don’t address flexible circuit-specific processes, or reluctance to share process capability data. A transparent supplier readily provides this documentation and welcomes detailed technical discussions about their manufacturing processes.

On-site facility audits reveal capabilities that documentation alone cannot verify. Walk the production floor to observe process controls, equipment maintenance, cleanroom protocols, and material handling procedures. Examine the supplier’s equipment portfolio—do they have roll-to-roll processing capabilities for high-volume production alongside sheet-by-sheet processing for prototyping and mixed production runs? Evaluate their testing infrastructure, including whether they maintain calibrated equipment for critical measurements like impedance testing, microsectioning, and flex endurance validation.

Pilot evaluations provide the definitive test of a supplier’s capabilities. Submit a challenging but representative design that exercises key technical requirements—perhaps a rigid-flex circuit with multiple bend zones, fine-pitch traces, and Class 3 inspection requirements. Evaluate not just whether the supplier delivers functional prototypes but how they handle the engineering collaboration process. Do they provide proactive DFM feedback? How do they respond to technical questions? What’s their yield performance, and how transparent are they about any quality issues discovered during production?

FlexPlus’s qualification process with new customers exemplifies this comprehensive approach. The company provides complete DFMEA analysis before prototype production, identifies potential manufacturing risks, and recommends design improvements to optimize yield. This engineering partnership continues through pilot production and into volume manufacturing, with direct access to production engineers ensuring rapid resolution of any issues that emerge.

Procurement Strategies and Risk Management

Building resilient supply chains for flexible circuits requires strategic approaches that extend beyond traditional supplier relationships. Single-sourcing creates vulnerability to capacity constraints, quality issues, or business disruptions. Yet qualifying multiple flexible PCB suppliers demands significant engineering resources and creates its own complexities around design standardization and quality consistency.

An Approved Supplier List (ASL) strategy balances these competing concerns. Maintain qualified primary and secondary suppliers for critical flexible circuit components, with clear qualification criteria and periodic re-evaluation processes. Your ASL should document each supplier’s certified capabilities, lead time ranges, minimum order quantities, and specific technical strengths. Some suppliers excel at ultra-thin designs for wearables, others specialize in automotive-certified rigid-flex circuits, while still others lead in medical-grade flexible circuits with biocompatible materials.

Risk mitigation extends beyond supplier diversification. Build buffer inventory for long-lead-time materials like specialized polyimide substrates or custom stiffener materials. Establish clear communication protocols for design changes, ensuring all suppliers receive synchronized updates to prevent version control issues. Implement incoming inspection procedures that verify critical parameters before circuits enter your assembly process, catching quality issues before they impact your production line.

Strategic supplier partnerships deliver benefits beyond risk reduction. Working closely with a manufacturer like FlexPlus, which offers comprehensive services from design consultation through full PCBA assembly, reduces vendor count and production delays while minimizing quality issues through integrated service. When your flexible circuit supplier also handles component sourcing, automated placement, and testing, you eliminate interface points where quality problems often emerge.

Consider the total cost of ownership when evaluating suppliers, not just piece prices. A slightly higher circuit cost from a qualified supplier with certified processes, comprehensive engineering support, and proven delivery performance costs far less than the production disruptions, quality escapes, and brand damage resulting from an unqualified supplier’s failures.

Practical Outcomes for Procurement Teams

Translating these qualification principles into actionable procurement strategies requires systematic implementation. Start by developing a supplier qualification scorecard that weights certification requirements, technical capabilities, quality metrics, and engineering support based on your specific application needs. Medical device manufacturers should emphasize ISO 13485 compliance and Class 3 workmanship capabilities. Automotive suppliers must verify IATF 16949 certification and automotive-grade material traceability. Aerospace applications demand AS9100 certification and comprehensive material testing documentation.

Build comprehensive testing plans that specify acceptance criteria for electrical performance, mechanical reliability, and environmental durability. For dynamic flex applications, require flexural endurance testing to specified cycle counts at your actual bend radii. For thermal environments, mandate thermal cycling validation across your operating temperature range. These testing requirements should be contractually binding, with clear rejection criteria and corrective action processes.

Schedule regular supplier audits—at least annually for critical suppliers—to verify continued compliance with certification requirements and assess process improvements or equipment upgrades. Use these audits as opportunities to review quality metrics, discuss capacity planning, and strengthen technical collaboration. The best supplier relationships evolve into true partnerships where both companies invest in mutual success through shared technical development and continuous improvement initiatives.

The flexible PCB industry continues advancing rapidly, with innovations like TPU circuits, transparent PCBs, and breakthrough thermal management solutions expanding application possibilities. Partnering with suppliers who invest in R&D and push technological boundaries positions your company to leverage these innovations for competitive advantage. FlexPlus’s development of flexible heat dissipation flow channels and ultra-thin 25-micron designs with gold plating exemplifies how leading manufacturers drive industry progress through material science breakthroughs and process innovation.

Conclusion

The seven critical certification gaps that could halt your production line—inadequate quality management systems, missing industry-specific certifications, insufficient DFM capabilities, material compliance failures, improper testing protocols, weak supplier qualification processes, and inadequate risk management strategies—all share a common thread. They stem from treating flexible PCB procurement as a transactional commodity purchase rather than a strategic engineering partnership requiring rigorous evaluation and ongoing collaboration.

Your flexible circuits form the nervous system of your electronic products, connecting components, enabling functionality, and often determining whether your product survives its operating environment or fails in the field. The supplier you choose to manufacture these critical components deserves the same systematic evaluation you apply to any mission-critical business decision. By implementing comprehensive qualification frameworks, demanding certified processes and transparent documentation, and building strategic partnerships with manufacturers who invest in engineering excellence, you transform your supply chain from a potential vulnerability into a competitive advantage that accelerates your product development and protects your brand reputation.