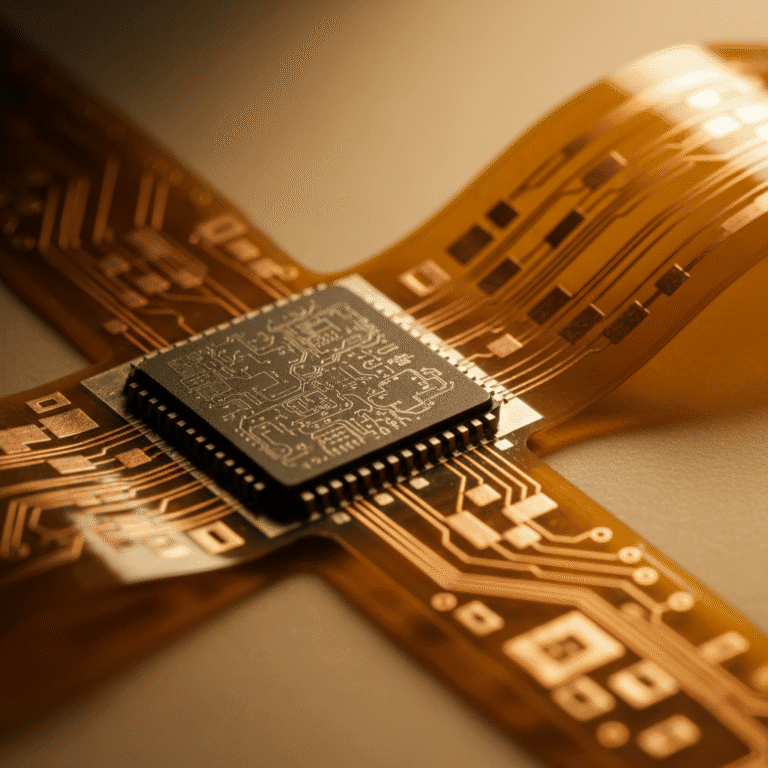

TPU Circuit Manufacturing: How Stretchable Electronics Are Revolutionizing Wearable Technology

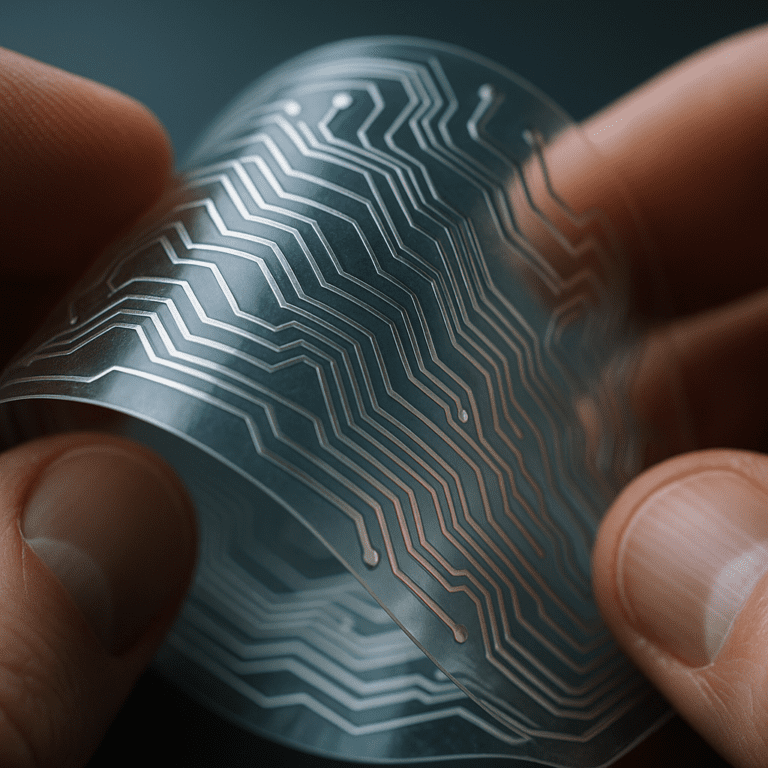

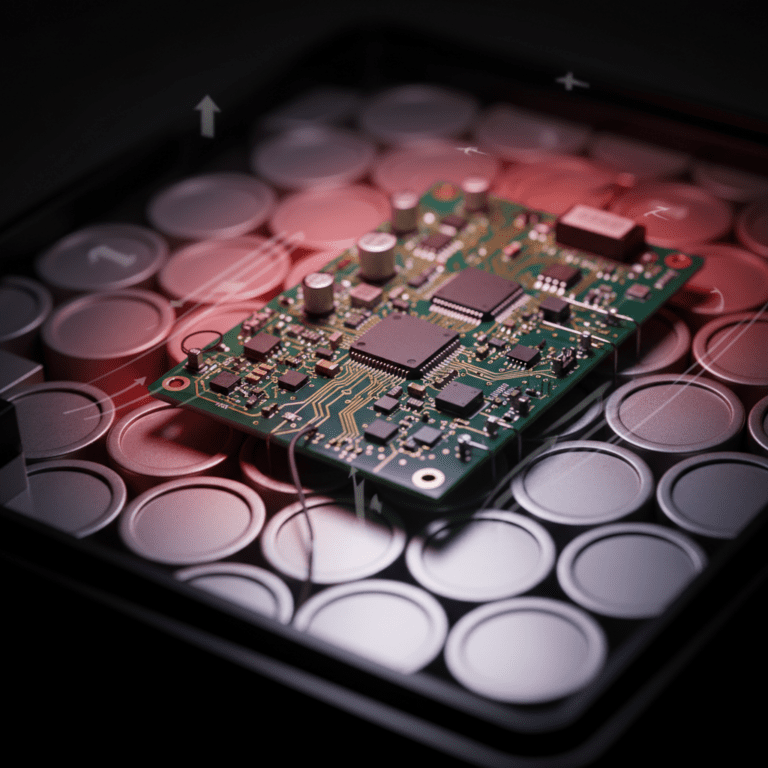

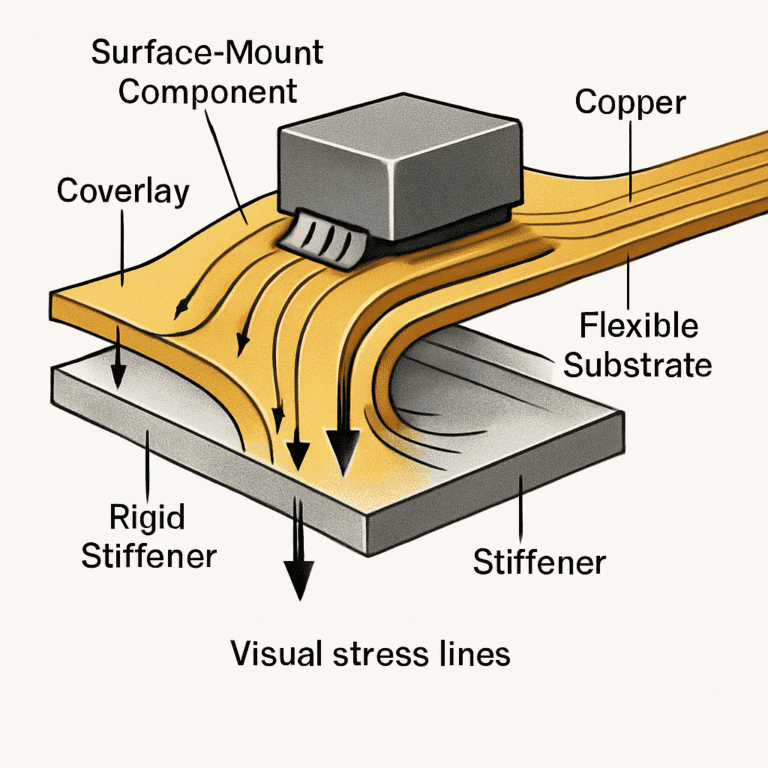

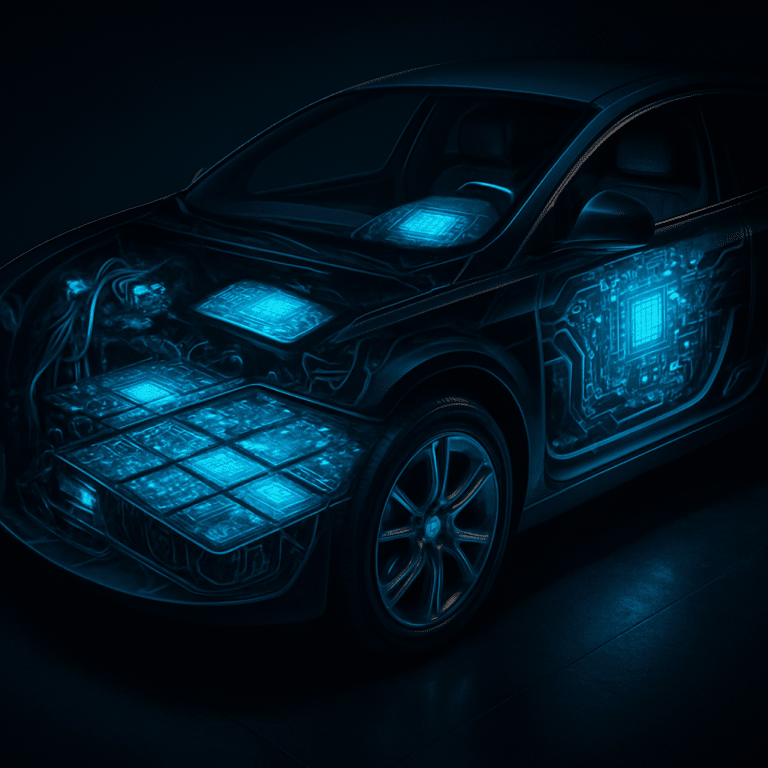

TPU circuit manufacturing is revolutionizing wearables with stretchable electronics that bend, flex, and conform to your body. From medical patches to smart textiles, these flexible circuits are transforming how we integrate technology into daily life, offering unprecedented comfort and functionality in next-generation devices. #TPU Circuit Manufacturing