The future of healthcare isn’t arriving with fanfare—it’s slipping quietly into our pockets, wrapping around our wrists, and even embedding itself beneath our skin. This silent revolution is powered by an unsung hero: miniaturized flexible PCB design. As medical devices shrink from bulky equipment to nearly invisible companions, they’re fundamentally changing how we monitor, diagnose, and treat health conditions. The technology enabling this transformation isn’t just making devices smaller; it’s making them disappear into the fabric of our daily lives.

The Push for Invisibility: Why Size Matters in Healthcare

In healthcare, bigger has never been better. For decades, patients have endured uncomfortable medical devices that restricted movement, caused irritation, and served as constant reminders of their health conditions. A pacemaker patient couldn’t forget their condition when they felt the bulky device beneath their skin. A diabetic had to interrupt their day multiple times to use finger-prick glucose monitors. These devices worked, but they didn’t integrate—they intruded.

Today’s healthcare landscape demands something different. Patients want continuous monitoring without constant awareness. They need diagnostic tools that travel with them, not equipment that keeps them tethered to hospitals. Medical professionals require real-time data streams from devices patients will actually wear consistently. This convergence of needs has created an urgent push toward miniaturization—not as a luxury, but as a necessity for effective modern healthcare.

The demand extends beyond patient comfort. Surgical tools need to reach previously inaccessible areas. Implantable devices must minimize tissue displacement. Wearable monitors need to be forgotten by their users to gather accurate, unbiased data. Every millimeter removed from a medical device potentially translates to better patient outcomes, higher compliance rates, and more effective treatment protocols. This is where miniaturized flex PCB design becomes not just an engineering achievement, but a healthcare imperative.

HDI PCBs: Packing Intelligence Into Impossibly Small Spaces

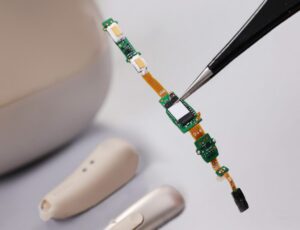

The backbone of medical device miniaturization is High-Density Interconnect (HDI) technology. Unlike traditional PCBs that space components relatively far apart, HDI PCBs use microvias—tiny holes measuring as small as 0.1mm—to create incredibly dense circuit layouts. This means more functionality, more sensors, more processing power, all compressed into spaces that would have been impossible just a decade ago.

Consider a modern continuous glucose monitor. This device, smaller than a coin, contains sensors, wireless transmitters, memory storage, and processing capabilities that would have required a briefcase-sized unit in the past. HDI technology makes this possible by stacking components vertically and creating multiple layers of interconnected circuits. Each layer communicates through those microscopic vias, creating a three-dimensional architecture of intelligence within a wafer-thin form factor.

But HDI technology alone doesn’t solve the healthcare miniaturization challenge. Medical devices must also conform to the human body—they need to bend, flex, and move with patients. A rigid circuit board, no matter how small, will always feel foreign against skin or inside tissue. This is where flexible PCBs enter the equation, bringing a dimension that HDI alone cannot provide.

Flexible PCBs transform the geometry of possibility. Instead of forcing medical devices into rigid rectangular shapes, engineers can now design circuits that wrap around limbs, curve with body contours, or fold into complex three-dimensional structures. A fitness tracker can hug a wrist smoothly. A cardiac monitor can conform to chest curvature. An implantable sensor can flex with organ movement without creating stress points that might cause failure or tissue damage.

The combination of HDI and flexible PCB technology represents a convergence of density and adaptability. Medical devices can now be both incredibly capable and remarkably unobtrusive. A smartwatch monitoring heart rhythm, blood oxygen, and ECG signals contains flexible HDI circuits that pack sophisticated medical-grade monitoring into a fashion accessory. This technological marriage has opened doors to wearable and implantable devices that earlier generations of engineers could only imagine.

Manufacturing Magic: How Extreme Miniaturization Becomes Reality

Achieving extreme miniaturization requires manufacturing techniques that border on the microscopic. Traditional PCB manufacturing simply cannot reach the precision levels required for next-generation medical devices. This has driven innovation in advanced manufacturing processes, with two technologies leading the charge: additive manufacturing (3D printing) and micro-electromechanical systems (MEMS).

Three-dimensional printing has revolutionized how engineers prototype and produce miniaturized circuits. Instead of etching away material from copper sheets—a subtractive process with inherent limitations—additive manufacturing builds circuits layer by layer with micron-level precision. This allows for complex three-dimensional circuit geometries that traditional manufacturing cannot produce. For medical devices requiring circuits that spiral, stack, or interweave in complex patterns, 3D printing provides solutions that were previously impossible.

MEMS technology takes miniaturization even further by integrating mechanical and electrical components at microscopic scales. MEMS sensors, smaller than a grain of sand, can detect pressure changes, measure acceleration, or respond to chemical markers. When integrated with wearable sensor devices in wireless body area networks, these components enable unprecedented monitoring capabilities. When integrated with flexible PCBs, these microscopic machines enable diagnostic capabilities in devices no larger than a bandage. A wearable sweat analyzer using MEMS sensors on a flexible circuit can monitor electrolyte levels, hydration status, and metabolic markers continuously—all while being completely forgotten by the wearer.

The manufacturing challenge extends beyond just making components smaller. Reliability cannot be compromised in medical applications. A fitness tracker might tolerate occasional glitches; a pacemaker cannot. This demands manufacturing processes with extraordinary consistency and quality control. Advanced techniques like laser drilling for microvias, sequential lamination for multilayer flex circuits, and automated optical inspection ensure that every miniaturized medical device meets stringent reliability standards.

At Flex Plus, this commitment to manufacturing excellence manifests in breakthrough capabilities like flexible substrate COB (Chip-on-Board) technology. By mounting ultra-thin chips directly onto flexible circuits, we achieve integration levels that push beyond traditional packaging limitations. The wafer offset angle tolerance controlled within ±5° and COB encapsulation thickness tolerance of 50-100μm represent the kind of precision that makes true miniaturization possible. These aren’t just manufacturing specifications—they’re the foundation for medical devices that can safely disappear into patients’ lives while maintaining absolute reliability.

The Engineering Tightrope: Balancing Size, Power, and Performance

Every engineer working on miniaturized medical devices faces the same fundamental challenge: as size decreases, complexity increases exponentially. It’s not enough to simply shrink components—you must also manage power consumption, heat dissipation, signal integrity, and electromagnetic compatibility, all within ever-tightening space constraints.

Power consumption becomes critical in miniaturized devices. A smartwatch with medical monitoring capabilities might need to run for days on a single charge while continuously sampling heart rate, blood oxygen, temperature, and motion data. This requires ultra-low-power circuit designs where every milliamp matters. Engineers must carefully select components that balance capability with efficiency, often customizing integrated circuits specifically for medical applications where off-the-shelf solutions consume too much power.

Heat dissipation presents another engineering challenge that intensifies with miniaturization. Smaller devices have less surface area to radiate heat, yet they often pack more processing power into those confined spaces. A medical device that becomes uncomfortably warm will be abandoned by patients, and excessive heat can damage sensitive electronics or, worse, harm tissue in implantable devices. Advanced thermal management solutions—including innovative approaches like flexible heat dissipation flow channels—have become essential for maintaining safe operating temperatures in miniaturized medical electronics.

Signal integrity and electromagnetic interference (EMI) grow more problematic as circuits become denser. When traces carrying different signals run close together, crosstalk can corrupt data. Understanding flexible PCB design rules becomes essential for maintaining performance in these dense layouts. When medical devices operate near smartphones, Wi-Fi routers, or other electronic equipment, electromagnetic interference can disrupt readings or functionality. Multilayer and rigid-flex PCBs help address these challenges by strategically routing sensitive signals through internal layers, using ground planes for shielding, and separating analog and digital circuits to maintain signal quality even in electrically noisy environments.

System-level considerations add yet another layer of complexity. Battery life must be maximized without adding bulk. Wireless connectivity options must be selected for range, power consumption, and compatibility with healthcare infrastructure. Sensors must be positioned for optimal data collection while maintaining the device’s small form factor. Enclosures must protect electronics from moisture, impacts, and body chemistry while remaining flexible and comfortable. Every decision involves trade-offs, and finding the optimal balance requires deep engineering expertise across multiple disciplines.

The Future Takes Shape: Where Miniaturization Leads Next

The trajectory of medical device miniaturization points toward a future where healthcare monitoring becomes truly continuous and invisible. We’re moving from devices patients put on and take off to technologies that become permanent companions, gathering data constantly and intervening proactively.

Personalized medicine will be the most profound beneficiary of this evolution. Current healthcare largely operates reactively—symptoms appear, tests are ordered, treatments begin. Miniaturized wearable and implantable devices enable a fundamental shift toward predictive, preventive medicine. A cardiac monitor detecting irregular rhythms before a patient feels symptoms can alert physicians to intervening before a heart attack occurs. A continuous metabolic sensor tracking glucose, ketones, and lactate levels can help diabetics optimize diet and medication in real-time rather than through trial and error.

Remote diagnostics represent another frontier opening through miniaturization. Telemedicine has proven its value, but it’s been limited to what can be observed through video calls and patient self-reporting. Miniaturized medical devices change this equation by providing objective, continuous data streams to remote physicians. A patient recovering at home from surgery can be monitored as closely as if they were in a hospital bed, with sensors tracking wound healing, infection markers, and vital signs 24/7. This extends specialized medical expertise beyond geographic boundaries while reducing healthcare costs and improving patient comfort.

The concept of smart implants is evolving rapidly. Today’s pacemakers are sophisticated, but tomorrow’s cardiac devices will integrate real-time monitoring with adaptive therapy, learning from each patient’s unique physiology and adjusting treatment dynamically. Neural implants for conditions like Parkinson’s disease or epilepsy will use miniaturized flexible circuits to interface with brain tissue more naturally, reducing side effects while improving therapeutic outcomes. Orthopedic implants will include sensors monitoring healing progress and detecting potential complications before they become serious problems.

Looking further ahead, miniaturized medical devices may integrate with emerging technologies like the Internet of Medical Things (IoMT) and artificial intelligence. Imagine a healthcare ecosystem where your wearable cardiovascular monitor communicates with your home’s environmental controls, adjusting temperature and humidity to optimize your heart health. Where your continuous glucose monitor talks to your smart refrigerator, suggesting meals based on your current metabolic state. Where patterns detected across thousands of patients inform treatment protocols that are then automatically customized to your specific physiology. This interconnected, intelligent healthcare future depends entirely on devices small enough, comfortable enough, and reliable enough to become invisible parts of daily life.

Engineering Tomorrow’s Healthcare: The Flex Plus Commitment

At Flex Plus (Xiamen) Co., Ltd, we see miniaturized flexible PCB design not as a technical specification but as a healthcare responsibility. For over 20 years, we’ve specialized in the advanced flexible and rigid-flex PCB solutions that make next-generation medical devices possible. Our ISO 13485 certification for biomedical-compatible flex PCBs reflects our understanding that in healthcare, quality isn’t negotiable—it’s fundamental.

Our approach to miniaturization extends beyond simply making things smaller. We’ve developed breakthrough capabilities like flexible COB integration that allow ultra-thin chips to be mounted directly onto flexible circuits, creating levels of integration that redefine what’s possible in compact medical devices. When engineers tell us they need circuits that bend, flex, and fit into spaces traditional manufacturing cannot reach, we respond with innovations like our ultra-thin designs achieving overall thickness as thin as 25 microns on double-sided flex PCBs with gold plating.

The diversity of medical applications we support—from wearable health monitors to implantable diagnostic devices—has taught us that one size never fits all in healthcare. That’s why we provide comprehensive design support from concept to mass production, offering DFM analysis, material consultation, and technical feedback that helps medical device innovators reduce risk and optimize performance. Whether it’s a rapid prototype needed within a week or scaling to high-volume production, our 8,000+ square meter factory with advanced sheet-by-sheet processing capabilities ensures we can support medical innovations at every stage of development.

We recognize that medical device manufacturers face unique challenges. Regulatory compliance, biocompatibility requirements, reliability standards that far exceed consumer electronics—these aren’t obstacles to work around but essential standards to uphold. Our certifications, including ISO 9001, IATF 16949, and IPC-6013 compliance, provide the foundation. But our real value comes from understanding how these standards translate into real-world healthcare improvements. When a cardiac monitor stays comfortable enough for a patient to wear continuously, it gathers data that saves lives. When an implantable sensor operates reliably for years without intervention, it improves patient outcomes while reducing healthcare costs. This is why we obsess over precision, from our ±5° wafer offset angle tolerance to our 50-100μm COB encapsulation thickness control.

The Invisible Revolution Continues

Medical devices are disappearing—not because they’re becoming less important, but because they’re becoming better. The bulky equipment that once reminded patients of their conditions every moment is giving way to companions so unobtrusive they can be forgotten. This transformation isn’t magic; it’s engineering. It’s the result of miniaturized flexible PCB designs that pack increasing intelligence into decreasing footprints while maintaining the reliability that healthcare demands.

The silent revolution making medical devices disappear into our lives represents a fundamental shift in how we approach health and wellness. We’re moving from episodic interactions with healthcare systems to continuous partnerships with intelligent devices that know us intimately and watch over us constantly. We’re transitioning from reactive medicine that treats symptoms to proactive healthcare that prevents problems before they begin. We’re evolving from one-size-fits-all protocols to personalized treatments optimized for each individual’s unique physiology.

Behind every innovation in this revolution—every fitness tracker that nudges us toward healthier choices, every implantable monitor that alerts physicians to emerging problems, every wearable device that makes chronic disease management less burdensome—sits a miniaturized flexible PCB. These circuits are the unsung infrastructure of modern healthcare, the invisible foundation supporting visible improvements in how we live, heal, and thrive.

As medical device manufacturers continue pushing boundaries, as patients demand increasingly unobtrusive monitoring solutions, and as healthcare systems seek more efficient ways to deliver care, the importance of advanced flexible PCB manufacturing will only grow. The devices of tomorrow will be smaller, smarter, and more integrated than today’s innovations—not because of any single breakthrough, but through continuous advancement in the foundational technologies that make miniaturization possible.

This is the future taking shape today, built one microscopic circuit at a time. And as these circuits disappear into devices that disappear into our lives, they’re quietly revolutionizing what healthcare can be—not something we visit occasionally, but something woven seamlessly into every moment, protecting and enhancing our health in ways we’ll increasingly take for granted. That’s the ultimate success of miniaturization: technology so effective, so unobtrusive, that it becomes invisible even as it becomes indispensable.