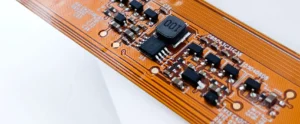

The smartphone in your pocket, the smartwatch on your wrist, and the advanced medical device monitoring your health all share a common thread: HDI flex circuits. These miniature marvels of engineering are quietly revolutionizing how we design and manufacture electronic devices. High Density Interconnect (HDI) flex circuits represent a fundamental shift in printed circuit board technology, combining the flexibility of traditional flex PCBs with unprecedented component density and performance capabilities.

HDI flex circuits achieve what seemed impossible just decades ago—packing more functionality into smaller spaces while maintaining reliability and performance. At their core, these circuits utilize advanced techniques like microvias, blind and buried vias, and ultra-fine traces to create pathways for electrical signals in spaces measured in microns. This isn’t just about making things smaller; it’s about enabling entirely new product categories that simply couldn’t exist without this technology.

Consider the evolution of smartphones. Each generation becomes thinner, lighter, and more powerful. This progression isn’t magic—it’s HDI flex circuit technology at work. By reducing the physical space required for electrical connections, designers can allocate more room for batteries, cameras, and other components that directly enhance user experience. The impact extends far beyond consumer electronics, touching everything from electric vehicle control systems to life-saving medical implants.

The Technical Foundation: Features That Make HDI Flex Circuits Essential

The revolutionary capabilities of HDI flex circuits stem from several key technical features that distinguish them from traditional PCB designs. Microvias represent perhaps the most significant advancement. These laser-drilled holes, typically measuring less than 150 microns in diameter, create electrical connections between layers with minimal space consumption. Unlike traditional mechanical drilling, laser technology enables via formation with precision measured in single-digit microns, opening possibilities for routing density that was previously unattainable.

Blind and buried vias further expand design flexibility. Blind vias connect an outer layer to one or more inner layers without penetrating the entire board thickness, while buried vias link internal layers without appearing on the surface. This three-dimensional approach to circuit routing dramatically increases the available wiring density. Designers can now create multiple signal pathways in the same footprint, essential for complex devices requiring hundreds or thousands of connections within millimeter-scale spaces.

The fine trace technology employed in HDI flex circuits pushes the boundaries of what’s possible in circuit design. Modern HDI manufacturing achieves line widths and spacing as narrow as 2 mils (approximately 50 microns), with some advanced facilities reaching even finer geometries. This precision enables higher circuit density while maintaining the electrical performance characteristics critical for high-speed data transmission.

These features combine to deliver tangible performance benefits. Signal integrity improves dramatically as shorter trace lengths reduce signal reflection, crosstalk, and electromagnetic interference. In high-speed applications—think 5G telecommunications equipment or advanced automotive sensors—maintaining signal integrity isn’t optional; it’s fundamental to device functionality. HDI flex circuits minimize the distance signals must travel, reducing propagation delay and enabling faster data transmission rates.

Space efficiency represents another crucial advantage. By stacking multiple layers of circuitry with microvias creating vertical connections, HDI flex circuits achieve component densities impossible with traditional PCB designs. This density translates directly into smaller, lighter end products—a critical requirement across industries from wearable technology to aerospace applications where every gram matters.

Manufacturing Innovation: The Processes Behind the Performance

The exceptional capabilities of HDI flex circuits don’t happen by accident. They result from sophisticated manufacturing techniques that represent decades of materials science and process engineering advancement. Direct metallization stands as one of the most significant innovations in HDI manufacturing. This process deposits copper directly onto non-conductive surfaces through electroless plating, creating reliable electrical connections without the weight and complexity of traditional through-hole plating. The result: lighter circuits with better electrical performance and enhanced reliability.

Sequential lamination, another cornerstone of HDI manufacturing, builds circuits layer by layer rather than laminating all layers simultaneously. This approach enables the creation of staggered and stacked microvias, maximizing routing density. Each layer undergoes drilling, plating, and circuit formation before the next layer is added, allowing for much finer feature sizes and tighter tolerances than conventional multilayer construction.

Laser drilling technology has transformed via formation in HDI circuits. CO2 and UV lasers precisely ablate material to create microvias with diameters and positional accuracy measured in microns. This precision enables the via-in-pad designs common in HDI circuits, where vias are placed directly within component pads to maximize routing density. The speed and accuracy of laser drilling make it economically viable to create thousands of microvias per board, something mechanical drilling simply cannot achieve at comparable cost and quality.

These advanced manufacturing techniques deliver dual benefits: enhanced reliability and reduced costs. By eliminating mechanical stress points associated with traditional drilling and enabling thinner dielectric layers, HDI manufacturing improves long-term reliability. Circuits withstand millions of flexing cycles in applications involving motion—critical for wearables, robotic systems, and automotive applications where vibration and movement are constant.

Cost reduction comes from layer count optimization. An HDI design might accomplish in four layers what would require eight layers in conventional PCB construction. Fewer layers mean less material, simpler manufacturing, and reduced weight—all translating to lower production costs and improved product economics. For manufacturers producing millions of units annually, these savings compound significantly.

The demand for these advanced manufacturing capabilities aligns perfectly with industry requirements for precision and high-performance PCBs. As devices become more sophisticated, the gap between what’s possible with conventional manufacturing and what’s required for next-generation products continues to widen. HDI flex circuit manufacturing bridges this gap, providing the foundation for innovation across multiple sectors.

Industry Impact: HDI Flex Circuits Enabling Innovation Across Sectors

The transformative impact of HDI flex circuits becomes clear when examining their applications across diverse industries. In the electric vehicle sector, these circuits are literally driving innovation. Modern EVs contain dozens of sophisticated electronic control units managing everything from battery performance to autonomous driving systems. HDI flex circuits enable the compact, reliable connections these systems require, fitting into constrained spaces while withstanding the harsh automotive environment of temperature extremes, vibration, and electromagnetic interference.

Head-up displays, advanced camera systems, and sensor arrays in electric vehicles all rely on HDI flex circuit technology. These applications demand both high-density interconnection for complex signal processing and the flexibility to conform to vehicle contours. A rigid PCB simply can’t curve around the windshield pillar or fit within the tight confines of a side mirror assembly. HDI flex circuits provide the solution, enabling automotive designers to place electronics wherever needed without compromising functionality or reliability.

Medical devices represent another critical application domain where HDI flex circuits are indispensable. Biomedical-compatible devices must be both reliable and miniature, fitting inside the human body or worn comfortably for extended periods. Cardiac monitoring devices, neural implants, and advanced diagnostic equipment all utilize HDI flex circuits to achieve functionality that would be impossible with traditional PCB technology. The ability to create ultra-thin, flexible circuits that withstand millions of flexing cycles proves essential for devices that move with the human body.

ISO 13485-certified manufacturing ensures that medical device HDI circuits meet stringent quality and traceability requirements. Every aspect of production, from material selection to final testing, follows documented procedures designed to ensure patient safety. This certification isn’t merely bureaucratic compliance—it represents a fundamental commitment to quality that medical device manufacturers absolutely require.

Consumer electronics continue to push HDI flex circuit technology forward. Smartphones exemplify this progression, with each generation packing more cameras, larger batteries, and faster processors into slimmer profiles. HDI flex circuits make this possible by routing complex signal pathways in minimal space. The main board in a modern flagship smartphone might contain eight or more layers of circuitry with thousands of microvias, all working seamlessly to deliver the performance users expect.

Wearable technology takes the challenge further, requiring circuits that are not only compact but also flexible enough to move with the user. Fitness trackers, smartwatches, and emerging augmented reality devices all depend on HDI flex circuits that can bend repeatedly without failure. The ability to create circuits that conform to curved surfaces while maintaining electrical performance enables entirely new product form factors.

Aerospace applications demand the ultimate in reliability, and HDI flex circuits deliver. Weight savings translate directly to improved fuel efficiency or extended range—critical factors in both commercial and military aviation. The vibration resistance and space efficiency of HDI flex circuits make them ideal for avionics, satellite systems, and other aerospace applications where failure isn’t an option. IATF 16949 certification ensures that manufacturing processes meet automotive industry standards also applicable to aerospace components, providing the quality assurance these demanding applications require.

Telecommunications infrastructure increasingly relies on HDI flex circuits for 5G equipment and optical transceivers. High-speed data transmission requires excellent signal integrity and minimal signal loss—characteristics that HDI design inherently provides. As networks evolve to support ever-higher bandwidths, the role of HDI flex circuits in maintaining signal quality becomes even more critical.

The Future Is Flexible, Dense, and Powerful

Looking forward, HDI flex circuit technology will only become more central to electronic device development. The convergence of artificial intelligence, Internet of Things, and advanced sensor technology creates unprecedented demands for compact, high-performance interconnection solutions. Devices must process more data, respond faster, and operate longer on smaller batteries—all while occupying less space. HDI flex circuits provide the foundation for meeting these seemingly contradictory requirements.

Emerging applications in low-altitude airspace technology, including drones and eVTOL vehicles, represent significant growth opportunities. These applications combine the harsh operating environment of aerospace with the cost sensitivity of consumer products. HDI flex circuits offer the reliability and performance these applications demand while maintaining manufacturing economics that enable commercial viability. Electric air taxis and aerial logistics systems will rely heavily on compact, lightweight electronics that HDI flex circuit technology uniquely enables.

The beauty technology sector demonstrates how HDI flex circuits enable innovation in unexpected places. Tech-driven beauty gadgets require sophisticated electronics in comfortable, aesthetically pleasing packages, leveraging high density interconnect flexible circuits to achieve unprecedented miniaturization. The flexibility and miniaturization that HDI circuits provide allow designers to create products that are both functional and wearable, opening new market categories that merge technology with personal care.

Smart helmet technology for applications ranging from Formula 1 racing to mining operations showcases another frontier for HDI flex circuits. These devices must integrate heads-up displays, communication systems, environmental sensors, and safety features into protective equipment that’s already constrained by size and weight requirements. HDI flex circuits make it possible to pack all this functionality into a helmet without compromising protection or comfort.

At Flex Plus (Xiamen) Co., Ltd, we understand that HDI flex circuits aren’t just products—they’re enablers of innovation. Our philosophy centers on providing cutting-edge solutions that support diverse industries in achieving their goals through superior PCB technology. With over 20 years of experience manufacturing flexible and rigid-flex circuits, we’ve developed deep expertise in the advanced manufacturing techniques that HDI circuits require.

Our IATF 16949, ISO 13485, and ISO 9001 certifications reflect our commitment to quality and precision. These aren’t just badges on our website—they represent systematic approaches to manufacturing that ensure every circuit we produce meets the exacting standards your applications demand. From electric vehicles to medical devices, from consumer electronics to aerospace systems, we provide the HDI flex circuit solutions that make next-generation products possible.

The future of electronics is smaller, smarter, and more powerful. HDI flex circuits are the foundation that makes this future possible. As devices continue to evolve, the role of these tiny powerhouses will only grow more essential. Whether you’re developing the next breakthrough wearable device, advancing automotive technology, or creating life-saving medical equipment, HDI flex circuits provide the connectivity, reliability, and performance your innovation requires.

The question isn’t whether your next device needs HDI flex circuit technology—it’s whether you’re partnering with manufacturers who truly understand how to deliver it. At Flex Plus, we combine advanced manufacturing capabilities with comprehensive engineering support, helping you navigate from concept to production with confidence. Because in today’s competitive landscape, having access to cutting-edge HDI flex circuit technology isn’t just an advantage—it’s a necessity.