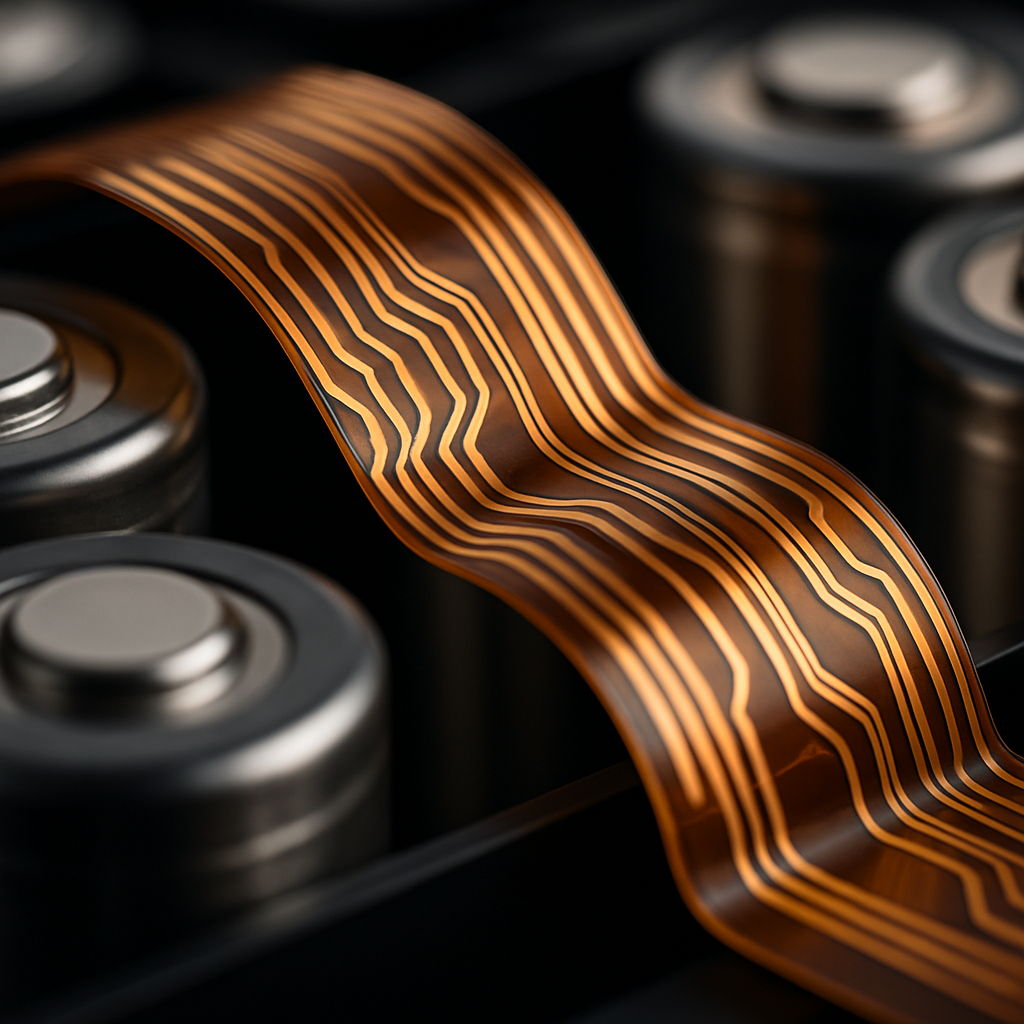

The smartphone in your pocket folds seamlessly. The medical device monitoring a patient’s vitals bends with body movement. The electric vehicle’s dashboard curves gracefully around its interior. Behind these engineering marvels lies a technology that’s revolutionizing how we design electronics: multilayer flexible printed circuit boards.

Unlike their simpler cousins—single or double-layer flex PCBs—multilayer flex PCBs stack three or more copper layers on a flexible substrate, creating complex electrical highways within incredibly thin, bendable packages. This isn’t just about adding layers; it’s about enabling electronics that were previously impossible to manufacture.

Think of it this way: a single-layer flex PCB is like a one-lane road. A double-layer is a two-way street. But a multilayer flex PCB? That’s a multi-level highway interchange, routing signals in three dimensions while maintaining the flexibility that modern devices demand. As electronics grow more sophisticated—packing more sensors, processors, and communication modules into smaller spaces—the question isn’t whether you need multilayer flex PCBs. It’s how quickly you can integrate them into your designs.

From automotive sensors that must survive extreme temperatures and constant vibration to medical implants that bend with human tissue, multilayer flex PCBs have become the backbone of industries where failure isn’t an option. Let’s explore why your complex electronics project might be the next one that needs more than two layers.

The Technical Foundation: What Makes Multilayer Flex PCBs Different

At its core, a multilayer flex PCB consists of three or more conductive copper layers separated by flexible insulating materials, typically polyimide. But this simple description doesn’t capture the engineering sophistication involved.

The magic happens in the interconnect density. Where a double-sided flex PCB limits you to two signal routing planes, multilayer designs offer three, four, six, or even eight separate copper layers. Each layer can carry different signals, power planes, or ground planes, dramatically increasing the circuit complexity you can achieve within the same footprint.

Consider a real-world scenario: An automotive sensor module needs to process signals from multiple temperature sensors, communicate via CAN bus, manage power distribution, and provide electromagnetic shielding—all within a 50mm × 30mm flexible circuit that must bend around the engine compartment. A double-layer design simply can’t accommodate this complexity without excessive connector counts or compromised signal integrity.

Multilayer flex PCBs solve this by stacking functionality vertically. The bottom layer might carry ground planes for EMI shielding. Middle layers route high-speed signals with controlled impedance. The top layer handles power distribution and low-speed control signals. This vertical integration eliminates the need for multiple separate PCBs connected by fragile wiring harnesses.

The space-saving capabilities are remarkable. In consumer electronics, particularly foldable smartphones like the Samsung Galaxy Z Fold series, multilayer flex PCBs enable screens that bend thousands of times without signal degradation. The circuit density achieved through multilayer construction allows manufacturers to integrate display drivers, touch sensors, and power management within the hinge mechanism itself—something impossible with rigid PCBs or simpler flex designs.

But greater complexity demands careful attention to design fundamentals. The bend radius becomes critical when routing signals through multiple layers. Each copper layer adds thickness, and the neutral axis—the plane within the flex PCB that experiences neither compression nor tension during bending—shifts with each additional layer. Engineers must calculate precisely how tight a bend radius the assembly can tolerate without cracking copper traces or delaminating layers.

Thermal management presents another challenge. While flexible substrates like polyimide offer excellent temperature resistance (typically -200°C to +400°C), dissipating heat through multiple copper layers requires strategic via placement and potential integration of thermal pathways. Understanding the materials used in flex PCB manufacturing helps engineers optimize thermal performance. At Flex Plus, we’ve pioneered flexible heat dissipation flow channels that address this exact challenge, creating thermal highways within the multilayer structure itself.

The materials matter enormously. High-quality polyimide substrates provide the mechanical flexibility while maintaining dimensional stability through thermal cycling. Copper conductors typically range from 18μm to 70μm (½ oz to 2 oz), with thinner copper offering better flexibility and heavier copper providing lower resistance for power applications. The adhesive systems bonding these layers must maintain integrity through thousands of flex cycles while withstanding the harsh chemical processes involved in manufacturing.

Electrical performance improves dramatically with multilayer designs. Dedicated ground and power planes reduce noise and crosstalk. Controlled impedance becomes achievable even in flexible substrates—essential for high-speed digital signals or RF applications. Signal integrity that would require bulky shielding or extensive routing tricks in two-layer designs becomes straightforward in multilayer construction.

Where Multilayer Flex PCBs Become Essential

The automotive industry has embraced multilayer flex PCBs as vehicles transform into sophisticated computer networks on wheels. Modern electric vehicles contain dozens of sensor clusters monitoring everything from battery cell temperatures to motor torque. Each sensor module needs robust signal processing, power management, and communication capabilities within assemblies that must survive -40°C winters, 125°C engine compartments, constant vibration, and exposure to moisture and chemicals.

A battery management system in an electric vehicle might use an eight-layer rigid-flex PCB that combines rigid sections for mounting connectors with flexible sections that snake between individual battery cells. The multilayer construction allows simultaneous voltage monitoring of dozens of cells, temperature sensing, current measurement, and high-speed communication with the vehicle’s main controller—all within a single integrated assembly that eliminates hundreds of discrete wire connections.

The reliability improvement is stunning. Traditional wire harnesses in automotive applications represent a significant failure point, with loose connections, broken wires, and connector corrosion causing warranty claims. By eliminating 87% of interconnection points through multilayer flex PCB integration, automotive suppliers achieve mean time between failure (MTBF) rates that were previously impossible.

Medical device manufacturers face even more stringent requirements. A wearable cardiac monitor must flex with body movement while maintaining precise signal integrity for EKG measurements. The multilayer flex PCB might integrate shielding layers to block electromagnetic interference, dedicated analog signal layers with carefully controlled impedance for EKG traces, digital processing layers for the microcontroller and memory, and power management layers—all within a circuit assembly thinner than a credit card.

The design challenges are substantial. Medical devices must meet biocompatibility standards, survive sterilization processes, and operate reliably for years. At Flex Plus, our ISO 13485 certification and medical-grade materials ensure that multilayer flex PCBs meet these rigorous standards. The polyimide substrates we use are biocompatible and can withstand repeated sterilization cycles without degradation.

Consumer electronics push multilayer flex PCBs in different directions—toward extreme miniaturization and cost optimization. The camera module in your smartphone likely contains a multilayer flex PCB connecting the image sensor, autofocus actuator, optical image stabilization system, and LED flash. This assembly must fit within a space barely 5mm thick while routing high-speed MIPI signals, multiple power rails, and control lines.

The precision required is extraordinary. Minimum trace widths of 0.05mm (2 mil) and layer-to-layer registration within 0.025mm ensure signal integrity at multi-gigabit data rates. These tolerances demand advanced manufacturing capabilities, including laser drilling for microvias and photolithography processes borrowed from semiconductor manufacturing.

Industrial control systems benefit from multilayer flex PCBs in applications involving moving machinery. Robotic arms use multilayer flex circuits that route dozens of sensor signals, motor control lines, and power feeds through constantly flexing joints. The multilayer construction allows complete signal separation, preventing the motor drive noise from interfering with sensitive position sensors.

The flex life requirements can be demanding—some industrial applications require millions of flex cycles. Design considerations include placing the neutral axis precisely at the center of the assembly, using rolled annealed copper that withstands flexing better than standard electrodeposited copper, and optimizing bend radius to minimize stress on individual copper layers.

The Manufacturing Journey: From Design to Reality

Manufacturing multilayer flex PCBs demands precision that borders on the microscopic. The process begins long before the first layer of copper meets polyimide—it starts with design for manufacturing (DFM) analysis.

At Flex Plus, our engineers work directly with customers during the design phase, identifying potential manufacturing issues before they become costly problems. Our professional PCB design services ensure manufacturing-ready files from the start. We evaluate layer stack-up configurations, via placement, bend radius requirements, and material selection. This collaborative approach reduces prototype iteration cycles dramatically. Where many manufacturers require multiple rounds of prototyping, our DFM expertise and quick turn PCB capabilities often deliver functional prototypes on the first build.

Material selection sets the foundation. High-quality polyimide substrates from certified suppliers ensure dimensional stability and consistent electrical properties. We maintain relationships with leading material manufacturers, giving us access to specialized substrates for demanding applications—from ultra-thin 25-micron polyimide for wearable devices to high-temperature polyimide for automotive applications.

The manufacturing process itself follows a carefully orchestrated sequence. Inner layer processing begins with copper-clad polyimide laminates. Photoresist coating, UV exposure through precision photomasks, and chemical etching create the circuit patterns on each layer. The registration accuracy between layers must be maintained within 25 microns—any misalignment causes via failures or short circuits.

Lamination represents a critical step where multiple layers bond together. Specialized adhesive systems or adhesiveless bonding techniques join the layers under precisely controlled heat and pressure. The challenge is achieving complete bonding without creating voids or delamination risks while maintaining the flexibility the finished product requires.

Drilling and via formation create the vertical connections between layers. Mechanical drilling handles larger holes for through-holes and component mounting. For high-density interconnects, laser drilling creates microvias with diameters as small as 0.1mm. The drilling depth must be precisely controlled—drill through too many layers and you short circuits together; stop too shallow and you don’t make electrical connection.

Plating processes deposit copper inside the drilled holes, creating conductive pathways between layers. Through-hole plating for multilayer flex PCBs requires careful control—the flexible substrate doesn’t provide the rigid mechanical support that traditional PCBs offer, making uniform copper deposition more challenging.

Surface finishing protects the copper and prepares it for soldering. Options include electroless nickel immersion gold (ENIG) for superior shelf life and bondability, immersion silver for cost-sensitive applications, or organic solderability preservatives (OSP) for environmentally friendly designs. For Flex Plus’s medical device customers, we offer specialized surface finishes that meet biocompatibility standards.

The challenges multiply with layer count. An eight-layer flex PCB requires seven lamination steps, each introducing potential quality risks. Maintaining registration across all layers while preserving flexibility demands process controls that few manufacturers master. Our 20+ years of specialized experience in flexible PCB manufacturing gives us the process maturity to achieve yields that exceed industry standards.

Cost considerations often surprise engineers new to multilayer flex PCBs. The tooling investment for multilayer designs exceeds that of simpler constructions. However, the system-level cost savings from eliminating connectors, reducing assembly complexity, and improving reliability often justify the higher PCB cost. A $50 rigid-flex PCB that replaces $200 worth of discrete PCBs, connectors, and wiring represents a net savings despite its higher unit cost.

Long-term reliability concerns focus on flex life. Repeated bending causes fatigue in copper conductors, potentially leading to trace cracking. Proper design—including optimized bend radius, rolled annealed copper, and strain relief features—ensures multilayer flex PCBs survive millions of flex cycles in demanding applications. We’ve conducted extensive flex testing on automotive applications, verifying performance through temperature cycling, vibration testing, and accelerated aging that simulates years of real-world use.

Quality control throughout manufacturing catches defects before they reach customers. Automated optical inspection (AOI) checks each layer for defects. Electrical testing verifies connectivity and impedance. For critical applications, we perform destructive cross-sectioning of sample boards, microscopically examining via quality, layer registration, and copper thickness. This comprehensive testing approach, certified under ISO 9001 and IATF 16949, ensures consistent quality whether you order ten prototypes or ten thousand production units.

Looking Ahead: Innovation in Multilayer Flex Technology

The evolution of multilayer flex PCBs continues accelerating, driven by emerging applications and advancing manufacturing capabilities. High-density interconnect (HDI) features—once exclusive to rigid PCBs—are migrating to flexible substrates, enabling trace widths and spacings of 50 microns or less. This increased density allows even more complex circuits within the same footprint.

Material innovation promises improved durability and performance. Next-generation polyimides offer enhanced tear resistance and improved flex life. Liquid crystal polymer (LCP) substrates provide lower dielectric constants for high-frequency applications, making multilayer flex PCBs viable for 5G antennas and millimeter-wave circuits. At Flex Plus, we’ve pioneered transparent PCB technology with transparency exceeding 90%, opening applications in augmented reality displays and transparent electronics.

The integration of rigid and flexible sections within the same assembly—rigid-flex PCBs—represents another evolutionary step. Modern rigid-flex designs can incorporate up to 12 layers, combining the reliability of rigid mounting areas with the space-saving advantages of flexible interconnections. For aerospace applications, this technology eliminates cable harnesses entirely, reducing aircraft weight by up to 60% in some subsystems.

Thermal management innovations continue advancing. Our proprietary flexible heat dissipation flow channels represent a breakthrough in managing heat within flexible assemblies. This technology creates engineered thermal pathways that conduct heat away from hot spots, enabling higher power densities in applications like high-brightness LED systems and power electronics.

Advanced manufacturing techniques promise to reduce costs while improving capabilities. Additive manufacturing processes—printing conductive traces rather than etching them—could eventually reduce material waste and enable rapid prototyping. Roll-to-roll processing for very high-volume production continues improving efficiency, making multilayer flex PCBs cost-competitive with rigid alternatives for consumer electronics.

The adoption of artificial intelligence in manufacturing optimization is beginning to impact yield rates and quality prediction. Machine learning algorithms analyze production data to predict potential defects before they occur, enabling real-time process adjustments that improve yield and reduce scrap.

At Flex Plus (Xiamen) Co., Ltd, our commitment to innovation extends beyond current capabilities to anticipate future customer needs. Our advanced flexible PCB manufacturing solutions focus on breakthrough technologies that solve real-world engineering challenges. We’re not satisfied with meeting industry standards—we’re setting them, whether through our industry-leading ultra-thin flex technology, our pioneering work in TPU circuits for medical and wearable applications, or our flexible COB integration solutions that achieve micron-level precision.

This philosophy of innovation and excellence drives everything we do. With over 20 years of specialized experience, certifications spanning ISO 9001, ISO 13485, IATF 16949, and ISO 14001, and a 16,000+ square meter state-of-the-art facility providing end-to-end manufacturing control, we deliver multilayer flex PCB solutions that meet the most stringent industry requirements. From rapid prototyping with turnaround times as short as three days to volume production with scalable capabilities, we partner with engineers and procurement teams to transform complex designs into reliable, manufacturable products.

As electronics continue evolving toward greater complexity, smaller form factors, and higher reliability requirements, multilayer flex PCBs will become not just advantageous but essential. The question for design engineers isn’t whether to adopt multilayer flex technology—it’s finding the right manufacturing partner to bring those designs to life with the precision, quality, and reliability that modern applications demand.