Selecting the right PCB assembly partner can make or break your product launch. For technical professionals across automotive, medical, industrial electronics, and aerospace sectors, this decision carries weight far beyond simple cost considerations. The wrong partner leads to quality inconsistencies, delayed timelines, and costly redesigns. The right partner becomes an extension of your engineering team, solving manufacturability challenges before they become production nightmares.

Design engineers face the challenge of translating intricate circuit layouts into manufacturable assemblies. Procurement specialists need suppliers who scale from prototypes to volume production without quality degradation. Quality assurance teams require partners with certified processes that meet stringent industry standards. Project managers need reliable delivery schedules that don’t derail entire product roadmaps.

These challenges intensify when products demand specialized capabilities—fine-pitch components in automotive sensors, biocompatible materials for medical implants, or aerospace-grade reliability in mission-critical systems. The assembly partner you choose directly impacts product performance, regulatory compliance, and market competitiveness.

Understanding What PCB Assembly Companies Actually Do

PCB assembly companies transform bare circuit boards into functional electronic assemblies through a comprehensive end-to-end process. This journey begins with component sourcing, where manufacturers procure resistors, capacitors, integrated circuits, and connectors specified in your Bill of Materials. The assembly phase follows, utilizing surface-mount technology (SMT) for miniaturized components and through-hole assembly for connectors and power components requiring mechanical strength.

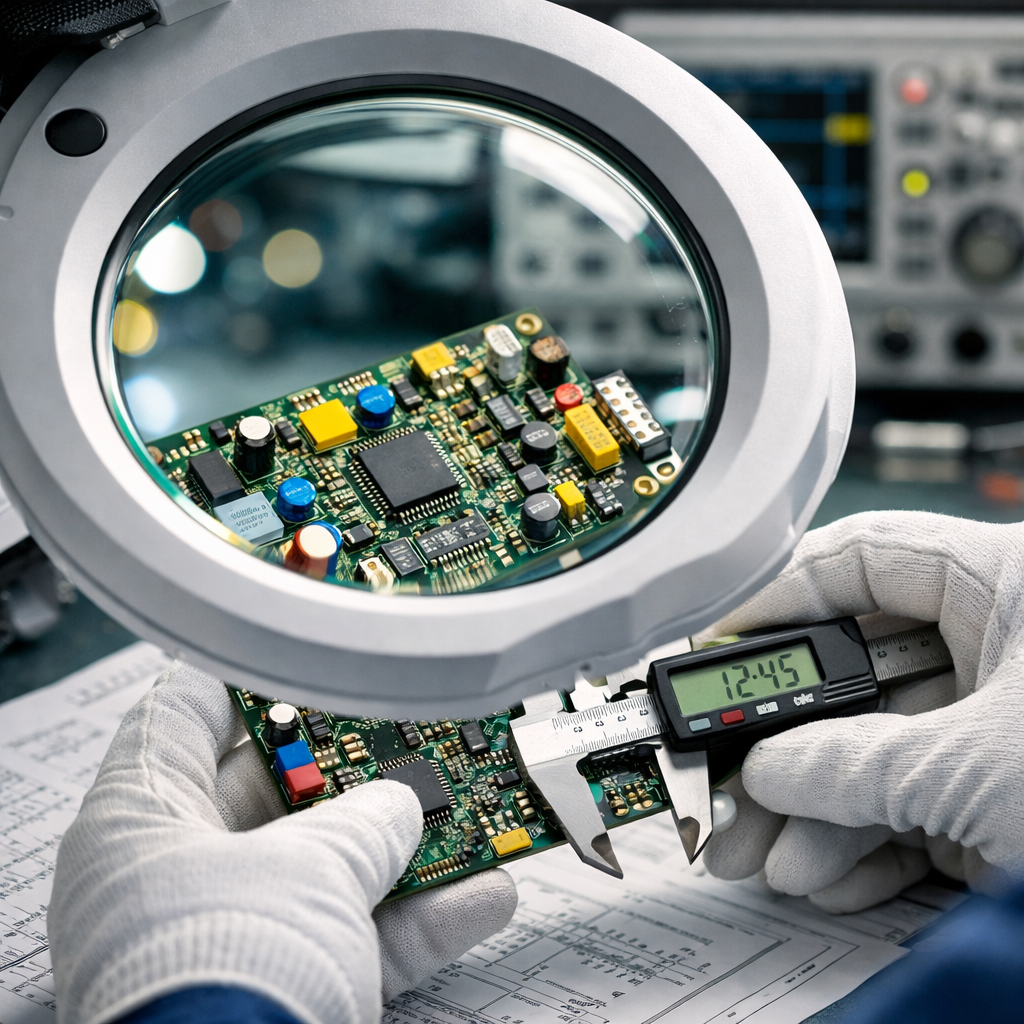

Soldering techniques vary based on component types and board complexity. Reflow soldering processes carefully control temperature profiles to ensure reliable solder joints without damaging heat-sensitive components. Wave soldering handles through-hole components efficiently in high-volume production. After assembly, rigorous testing verifies electrical functionality through automated optical inspection (AOI), X-ray inspection for hidden solder joints, and in-circuit testing to catch defects before final packaging.

Understanding service models helps you select the right approach for your project needs. Turnkey assembly means your manufacturing partner handles everything—component procurement, board fabrication, assembly, testing, and packaging. You provide design files and specifications; they deliver finished assemblies. This streamlined approach reduces vendor management overhead and accelerates time-to-market, particularly valuable for companies without dedicated procurement teams or established component supplier relationships.

Partial turnkey services split responsibilities. You might supply critical or long-lead-time components while the manufacturer sources standard parts. This hybrid approach offers control over specialized components while leveraging the manufacturer’s purchasing power for commodity items. It works well when you have existing supplier relationships for proprietary components or need to manage specific component lifecycles.

Kitted or consigned services require you to deliver all components to the assembly house. The manufacturer focuses purely on assembly and testing. While this model offers maximum component control, it demands sophisticated supply chain management on your end. You bear the risk of component shortages, obsolescence, and inventory management. This approach makes sense for companies with mature procurement operations or products with highly specialized component requirements.

Core Services and Capabilities That Separate Leaders from Followers

When comparing potential assembly partners, prototyping support reveals much about their engineering capabilities. Leading manufacturers offer comprehensive Design for Manufacturing (DFM) support, analyzing your designs for potential assembly challenges before committing to production. They identify issues like insufficient spacing between components that complicate automated assembly, awkward connector placement interfering with board access, or thermal management concerns that could cause field failures.

The gap between prototype and volume production destroys many promising products. Look for partners who seamlessly transition from quick-turn prototypes to high-volume manufacturing. FlexPlus demonstrates this capability through rapid prototyping with standard turnarounds within one week and emergency requests completed in three days, then scaling smoothly to volume production without compromising quality standards established during prototyping.

Manufacturing capabilities determine what you can actually build. Surface-mount technology (SMT) capacity matters—specifically, the ability to handle fine-pitch components as small as 0.4mm spacing. This capability becomes critical for compact consumer electronics and high-density medical devices. Through-hole assembly capacity remains essential for connectors, power components, and applications requiring mechanical robustness. Mixed-technology assembly, combining SMT and through-hole on the same board, demands coordinated process control to avoid damaging components during multiple assembly stages.

Advanced capabilities separate capable manufacturers from exceptional ones. High-density interconnect (HDI) expertise enables miniaturized designs with minimum trace widths down to 0.05mm (2mil). X-ray inspection capability ensures reliable solder joints on ball grid arrays (BGAs) and other components with hidden connections. Conformal coating application protects assemblies from moisture, chemicals, and environmental stress in harsh operating conditions.

Quality systems provide the foundation for consistent production. ISO 9001 certification demonstrates commitment to quality management systems, but industry-specific certifications reveal deeper expertise. ISO 13485 certification signals competence in medical device manufacturing with stringent traceability and process control requirements. IATF 16949 certification indicates automotive industry expertise meeting demanding reliability and quality standards. IPC-A-610 acceptance criteria ensure consistent workmanship standards across production batches.

These certifications aren’t mere paperwork—they represent systematic approaches to process control, continuous improvement, and risk management that protect your production from costly surprises.

Understanding the True Cost of PCB Assembly

Pricing transparency separates professional manufacturers from those hiding costs in vague quotes. The Bill of Materials (BOM) cost typically represents the largest expense, particularly for complex assemblies. Component prices fluctuate with market conditions, and experienced manufacturers leverage purchasing relationships to secure favorable pricing even during shortages. They also catch BOM issues early—obsolete part numbers, unnecessarily expensive components when equivalent alternatives exist, or single-source components creating supply chain vulnerabilities.

Assembly labor costs vary with board complexity and component density. Fine-pitch components require sophisticated placement equipment and skilled operators. Double-sided assemblies double handling time. Mixed-technology boards combining SMT and through-hole components add process steps. Volume dramatically impacts per-unit costs—setup costs spread across thousands of units become negligible, but the same setup divided by fifty prototypes significantly increases unit pricing.

Testing and inspection costs reflect quality assurance rigor. Automated optical inspection (AOI) catches placement errors and solder defects. X-ray inspection for BGAs and hidden joints adds cost but prevents field failures. Functional testing verifies that assembled boards perform as designed, catching electrical issues before shipping. Companies cutting corners on testing deliver cheaper quotes but costlier field failures.

Packaging and logistics seem minor but impact total project cost. Proper packaging prevents damage during shipping—ESD-protective bags for sensitive electronics, cushioning for heavy assemblies, moisture barrier bags for boards requiring dry storage before secondary operations. International shipping requires customs documentation and duty management. Experienced manufacturers handle these details, preventing delivery delays and damage claims.

Surface finishes affect both cost and performance. Hot air solder leveling (HASL) offers economical protection for general applications. Electroless nickel immersion gold (ENIG) provides excellent solderability and wire bonding compatibility for advanced packages, though at higher cost. Immersion silver and immersion tin offer cost-performance compromises for specific applications. Your assembly partner should recommend appropriate finishes based on component types, soldering processes, and operating environment.

Hidden costs emerge from poor partner selection. Rework costs from assembly defects, redesign costs from unidentified DFM issues, expedited shipping costs recovering from delivery delays, and opportunity costs from missed market windows dwarf apparent savings from lowest-bid suppliers.

Practical Tips for Evaluating PCB Assembly Providers

Define your project needs clearly before approaching potential partners. Specify production volumes—prototype quantities, initial production runs, and anticipated volume ramps. Detail technical requirements including component types, board complexity, density, special processes like conformal coating, and any regulatory requirements. Establish timeline expectations for prototyping, pre-production runs, and volume manufacturing. This clarity enables meaningful comparisons between suppliers.

Request detailed quotes breaking down component costs, assembly labor, testing and inspection, tooling or setup fees, and shipping. Itemized quotes reveal where costs accumulate and identify red flags—suppliers quoting unrealistically low component costs may substitute inferior parts or lack purchasing relationships delivering stated pricing. Vague “all-inclusive” quotes hide costs that emerge later as change orders.

Evaluate beyond price alone. The cheapest quote often signals problems—inadequate testing procedures, minimal engineering support, or optimistic lead times assuming perfect execution. Calculate total cost of ownership including engineering support value, quality failure risk, delivery reliability, and communication efficiency. A slightly higher quote from a partner providing comprehensive DFM analysis and reliable delivery often costs less than a rock-bottom quote from a manufacturer requiring multiple revision cycles and expedited shipping.

Consider supply chain logistics carefully. Lead times vary between manufacturers based on component sourcing efficiency, production scheduling practices, and internal process control. Component availability dramatically impacts production schedules—manufacturers with strong supplier relationships navigate shortages better than those relying on spot market purchases. Geographic location affects shipping costs and times but also communication—real-time conversations solving problems beat asynchronous email exchanges spanning time zones.

Review references and track records rigorously. Request customer references in your industry—medical device manufacturers for medical projects, automotive suppliers for automotive applications. Industry experience matters because regulatory requirements, reliability standards, and design constraints vary dramatically across sectors. Ask specific questions about communication responsiveness, problem-solving approaches when issues arise, and consistency between prototype and production quality.

Assess engineering support capabilities through initial interactions. Responsive manufacturers answer technical questions thoroughly, provide DFM feedback on submitted designs, and propose optimization opportunities reducing cost or improving reliability. Manufacturers treating you like order-takers rather than partners signal problems ahead when complex issues require collaborative problem-solving.

The Current Industry Landscape

The PCB assembly industry includes established leaders providing comprehensive manufacturing services to electronics companies globally. Major players like Jabil, Flex Ltd., and Foxconn operate worldwide with facilities in multiple regions, serving customers from prototyping through volume production. These companies offer full turnkey services including design support, component procurement, assembly, testing, and supply chain management.

Mid-sized specialists focus on particular market segments or technical capabilities. Some concentrate on quick-turn prototyping with rapid response times. Others specialize in high-reliability applications for aerospace, defense, or medical devices, maintaining certifications and processes meeting stringent industry standards. Regional manufacturers serve local markets with shorter shipping times and cultural alignment.

Quality systems distinguish professional manufacturers from commodity assemblers. Leading companies maintain multiple ISO certifications demonstrating systematic quality management. Industry-specific certifications like ISO 13485 for medical devices or IATF 16949 for automotive applications indicate specialized expertise and process maturity. IPC standards compliance ensures workmanship quality and reliability.

Global reach enables manufacturers to serve customers worldwide while maintaining consistent quality across facilities. This geographic distribution provides redundancy protecting customers from regional disruptions, local presence reducing shipping times and costs, and access to regional component markets and specialized suppliers.

The most capable assembly partners combine manufacturing scale with engineering partnership. They don’t simply execute assembly instructions—they collaborate on design optimization, component selection, and process development. This partnership approach transforms them from vendors into strategic partners supporting product success from concept through production.

Making the Right Choice: Balancing Cost, Quality, Capacity, and Agility

Successful PCB assembly partnerships balance multiple factors beyond initial price quotes. Cost competitiveness matters, but quality consistency prevents expensive field failures and warranty claims that dwarf assembly cost savings. Manufacturing capacity determines whether your partner scales with your business growth or becomes a bottleneck constraining market opportunities. Delivery agility enables rapid response to market demands, component shortages, or design changes inevitable in product development.

The optimal partner combines technical capabilities matching your requirements, quality systems ensuring consistent production, engineering support optimizing designs for manufacturability, supply chain strength navigating component markets, and communication effectiveness solving problems collaboratively.

Flex Plus (Xiamen) Co., Ltd embodies these qualities through 20+ years specializing in flexible and rigid-flex PCB solutions. Our end-to-end manufacturing control eliminates middleman delays and quality inconsistencies. Direct communication with production engineers enables rapid problem-solving and design optimization. Comprehensive certifications—ISO 9001, ISO 13485, IATF 16949, ISO 14001—demonstrate systematic quality management and industry-specific expertise.

Our commitment extends beyond manufacturing to genuine engineering partnership. We provide DFM analysis identifying manufacturability challenges early, material consultation optimizing substrate and component selection, and rapid prototyping enabling fast iteration cycles. Advanced capabilities including ultra-thin designs down to 25 microns, TPU circuit innovation for wearable applications, and flexible COB integration position us at technology’s leading edge.

When selecting your PCB assembly partner, look beyond price to find a manufacturer sharing your commitment to innovation, quality, and reliable delivery. The right partner doesn’t just assemble boards—they help you succeed in competitive markets through technical excellence and collaborative problem-solving. Your choice today determines your product’s success tomorrow.