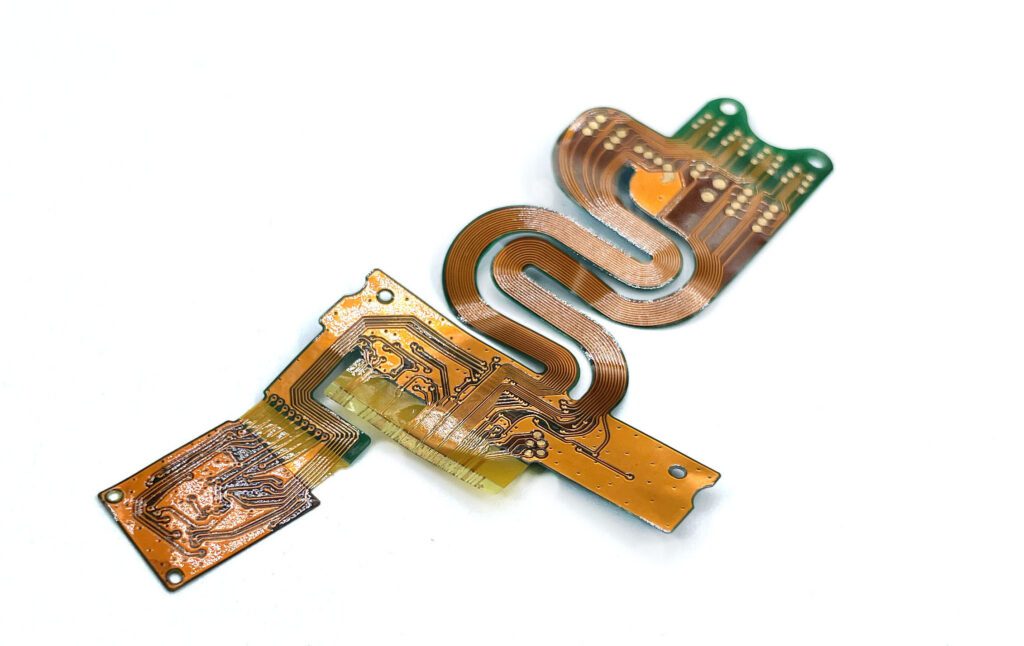

Dynamic Flex PCB Design: Why Your Bending Circuit Fails After 1000 Cycles

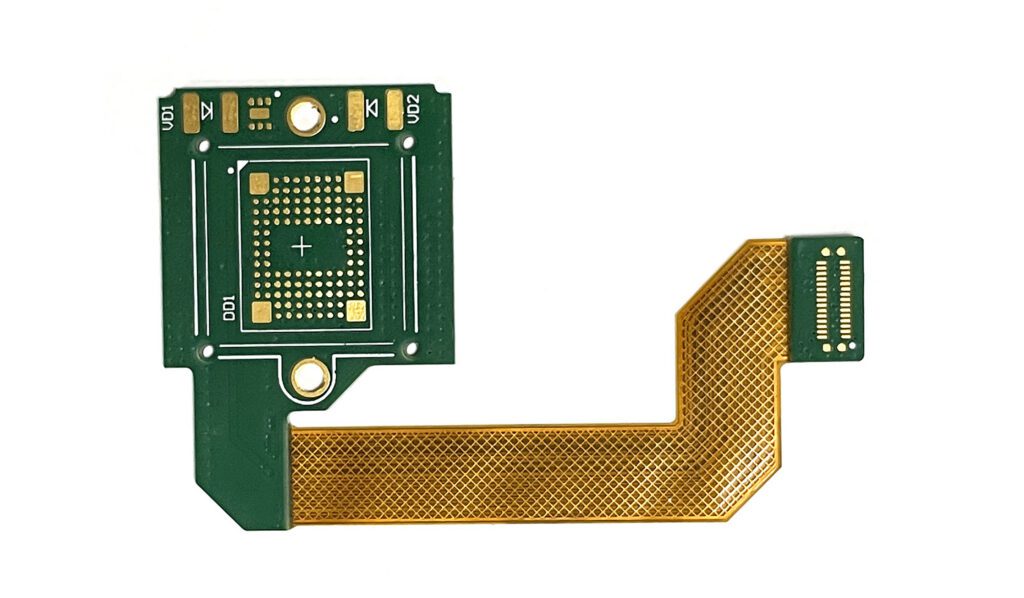

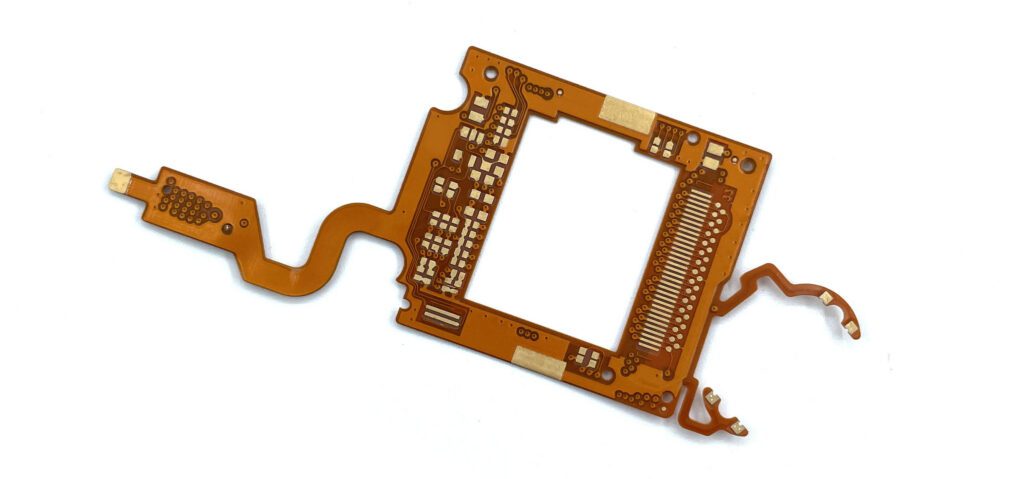

Frustrated by flex PCBs cracking after 1000 cycles? Learn why dynamic flex circuits fail and discover proven engineering strategies for material selection, bend radius optimization, and stress management that ensure reliability beyond 100,000 cycles in mission-critical applications. #dynamic flex pcb design