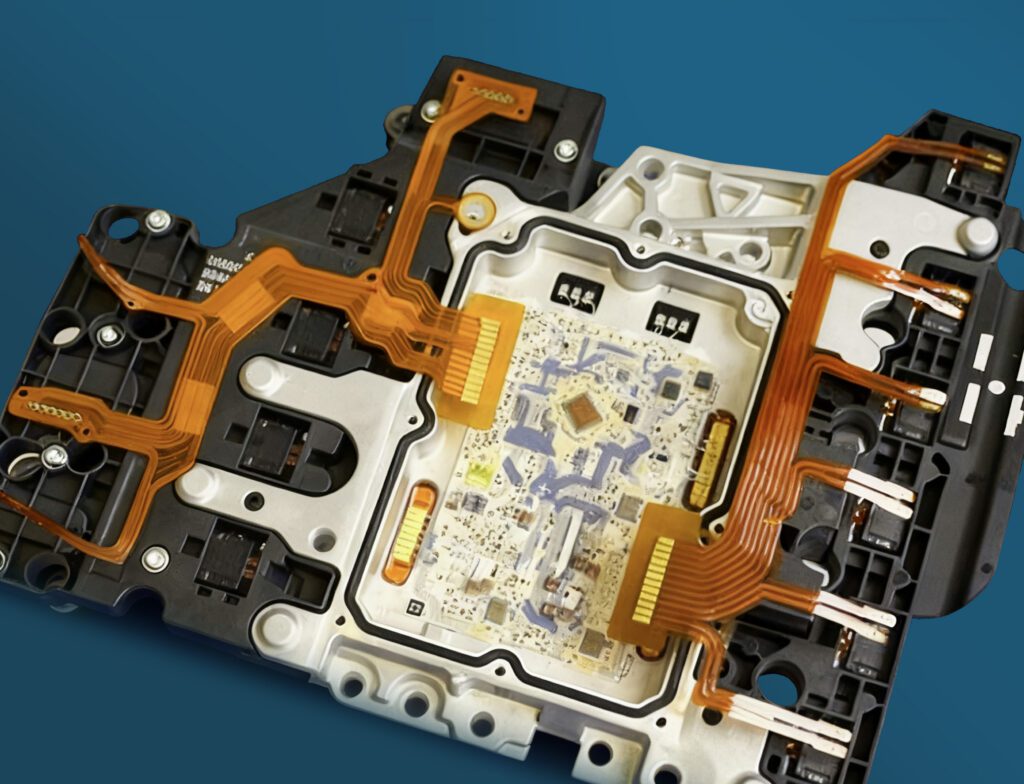

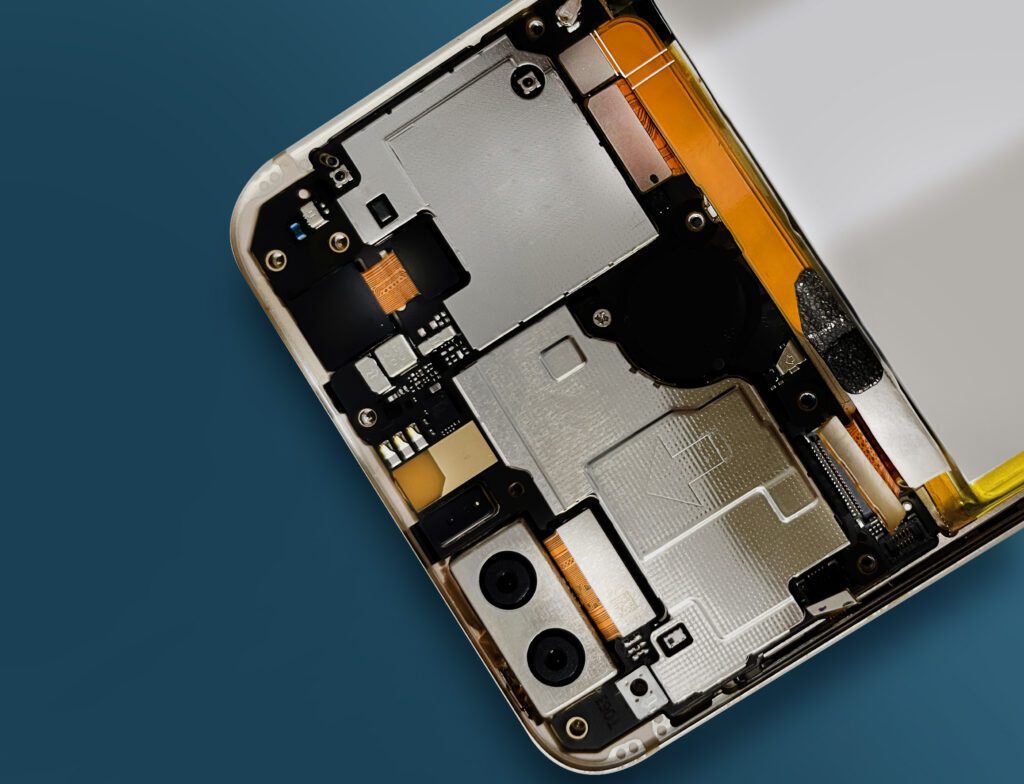

Flex PCB Stiffener Design: Preventing Component Failure in High-Stress Flex Circuits

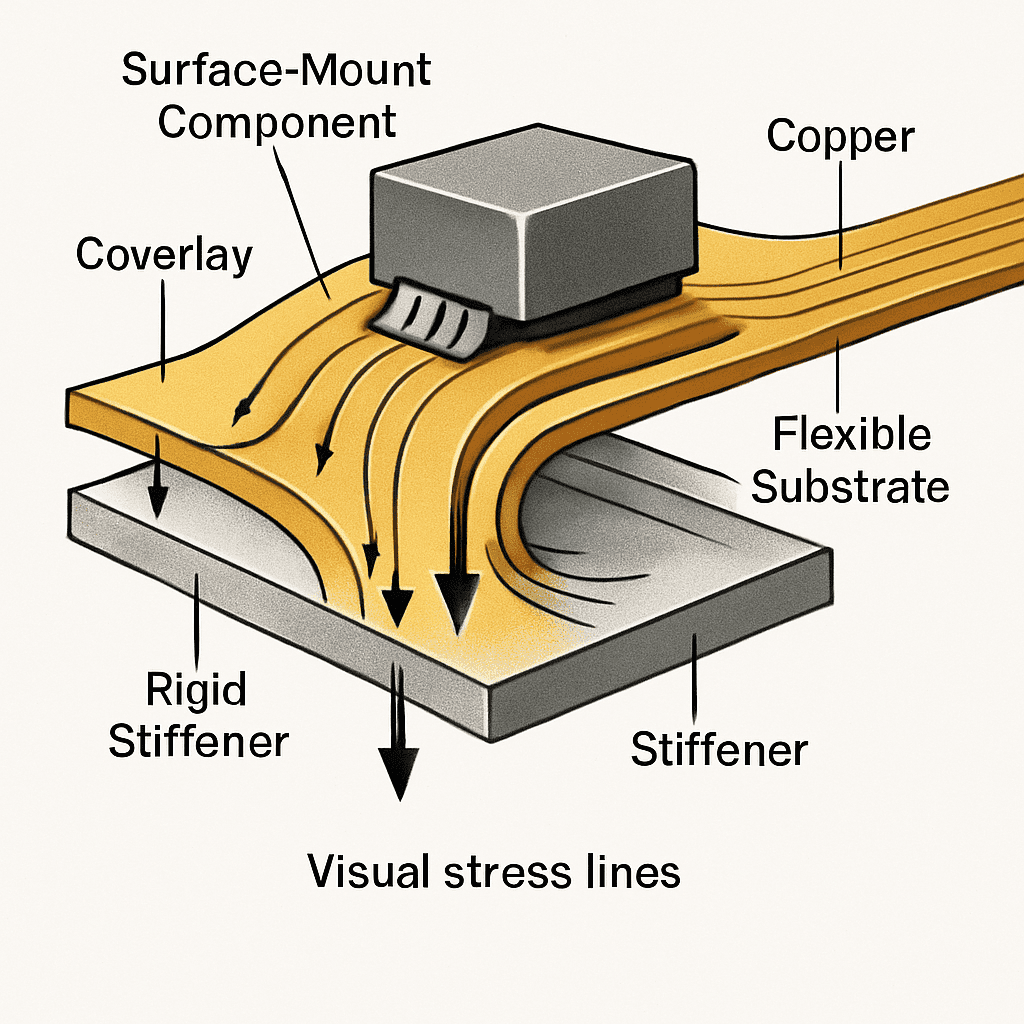

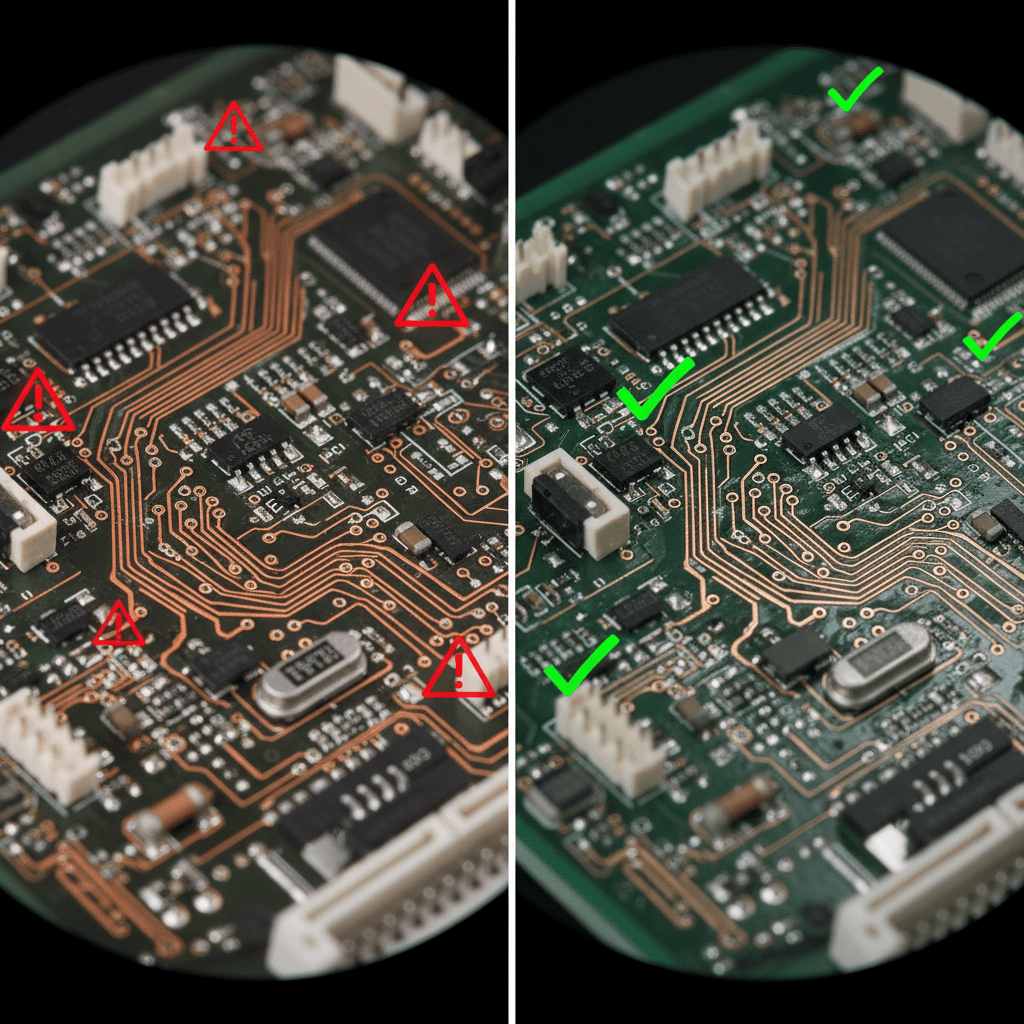

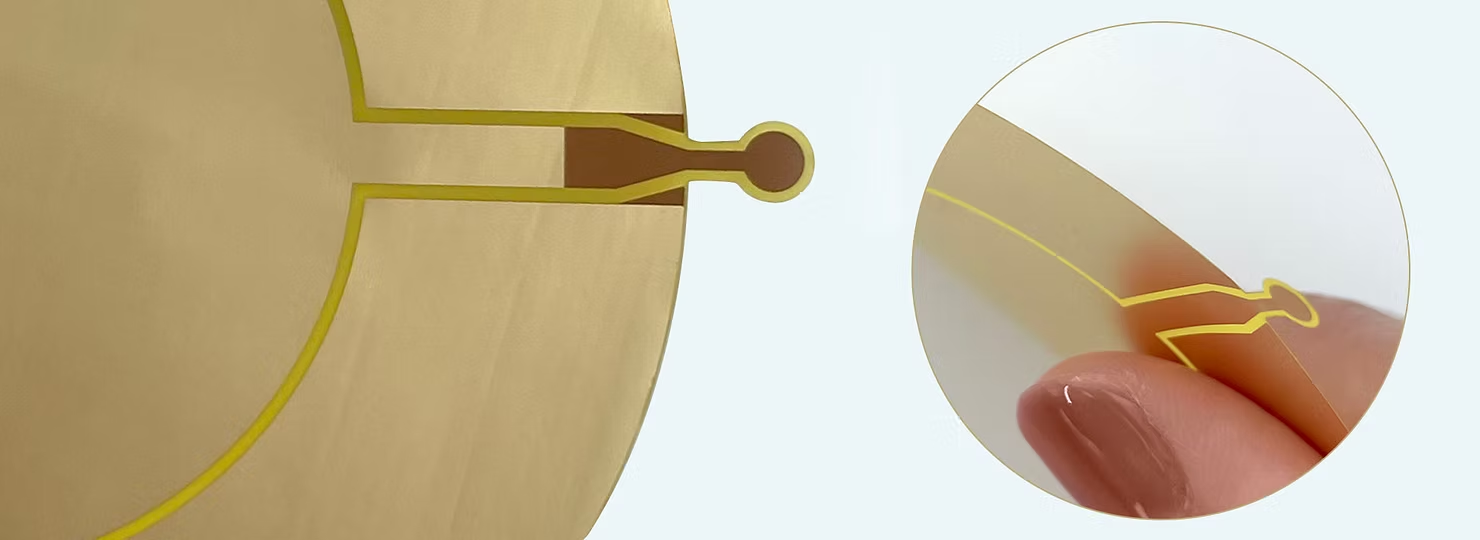

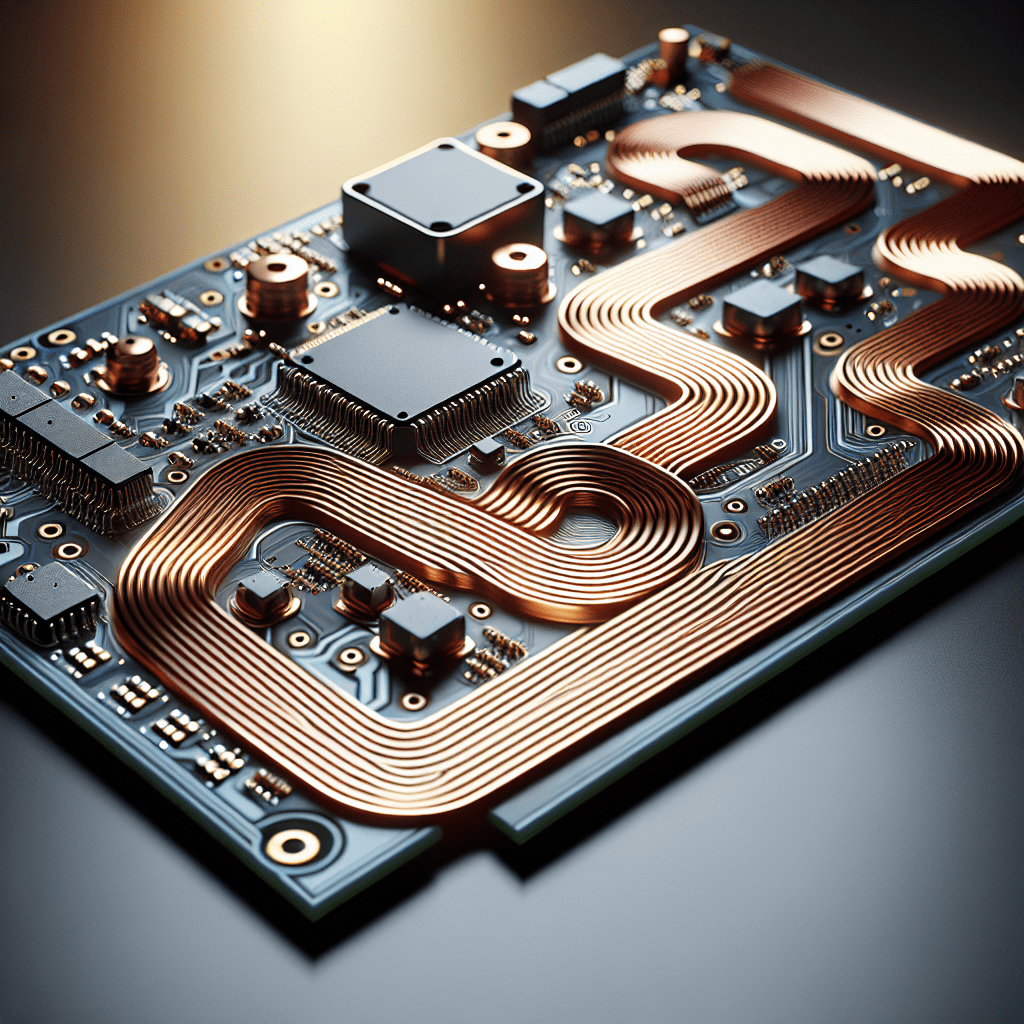

Strategic stiffener placement protects critical zones in flex circuits from mechanical stress, preventing component and connector failures in automotive, medical, and industrial applications. Learn material selection, design guidelines, and manufacturing best practices for reliable high-stress flexible PCB implementations. #flex pcb stiffener