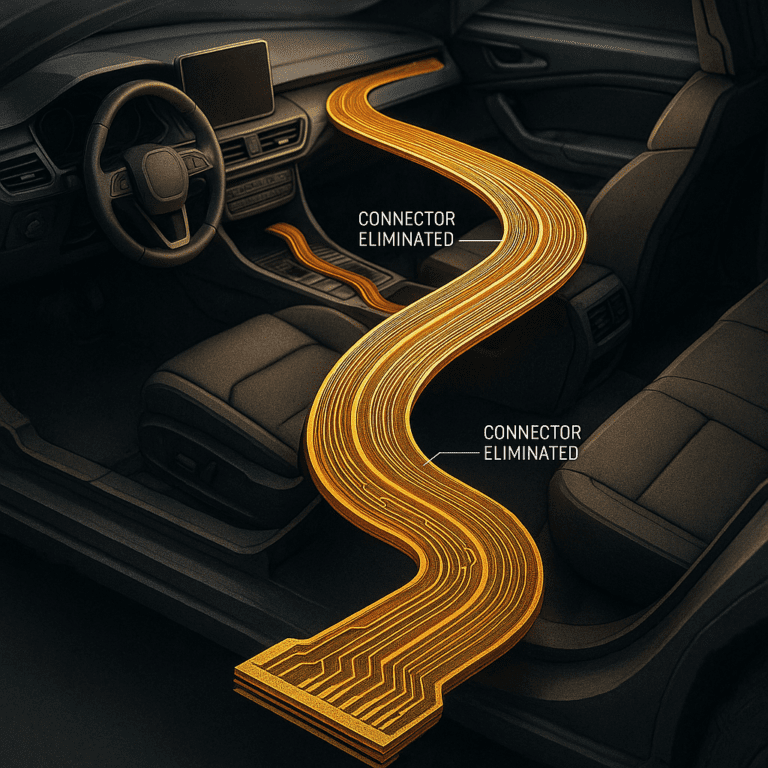

Flexible Interconnection: The Hidden Engineering Challenge Transforming Wearables, EVs, and Medical Devices

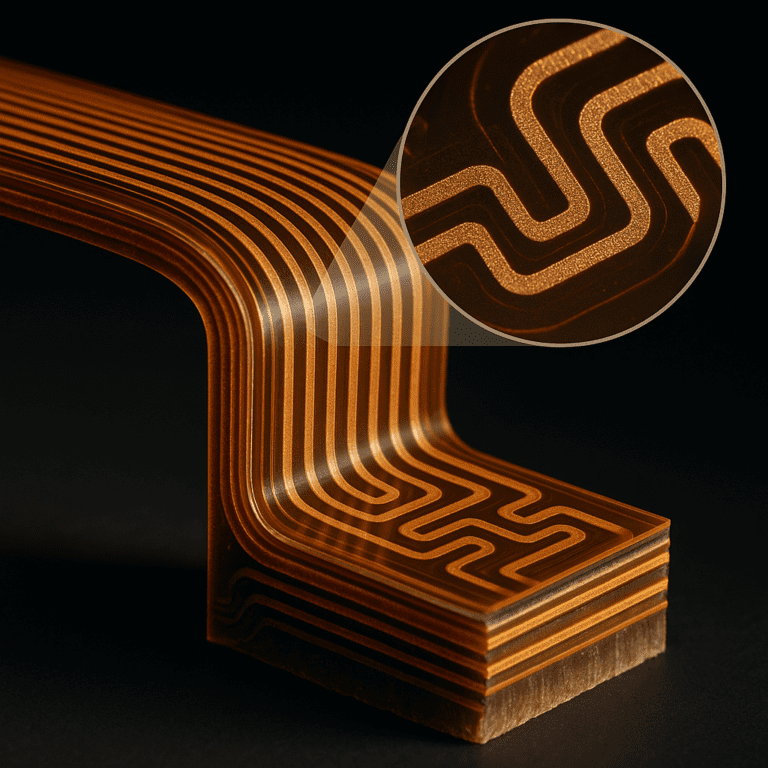

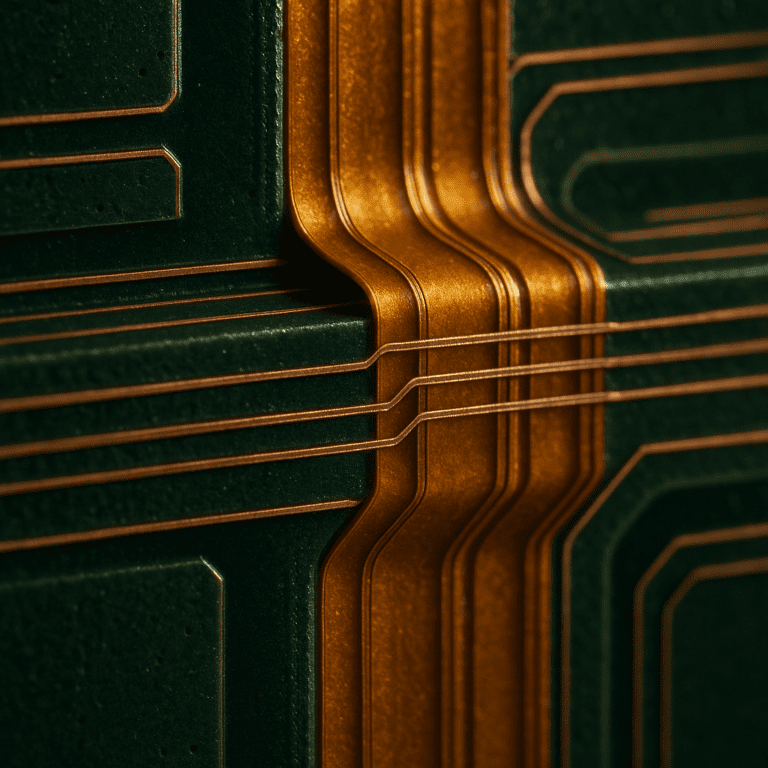

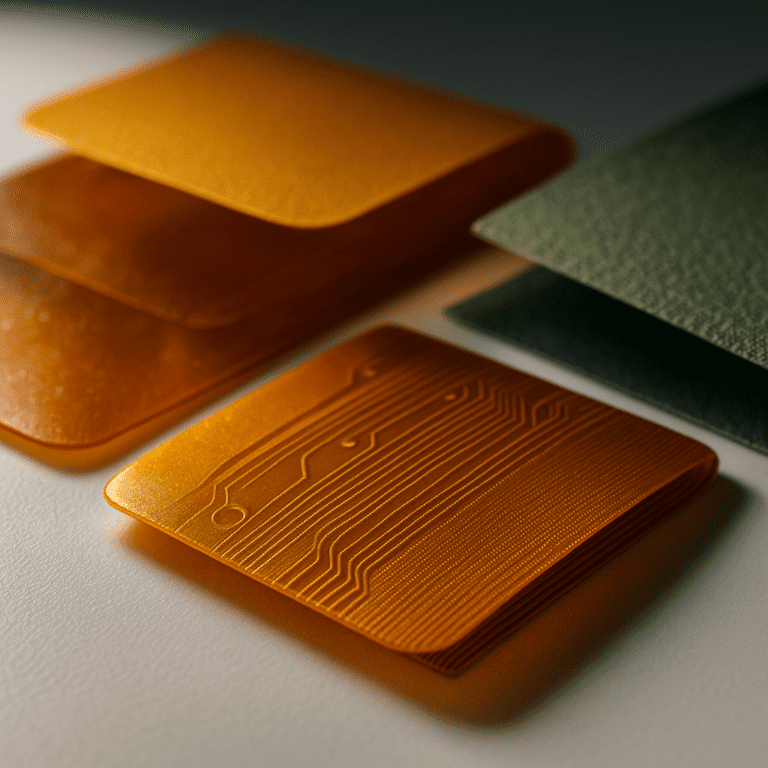

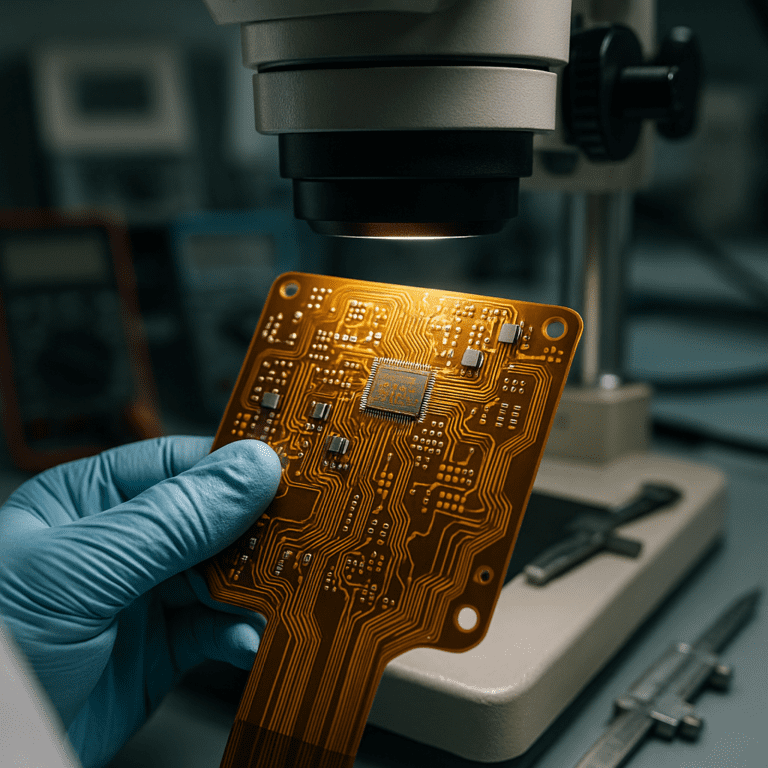

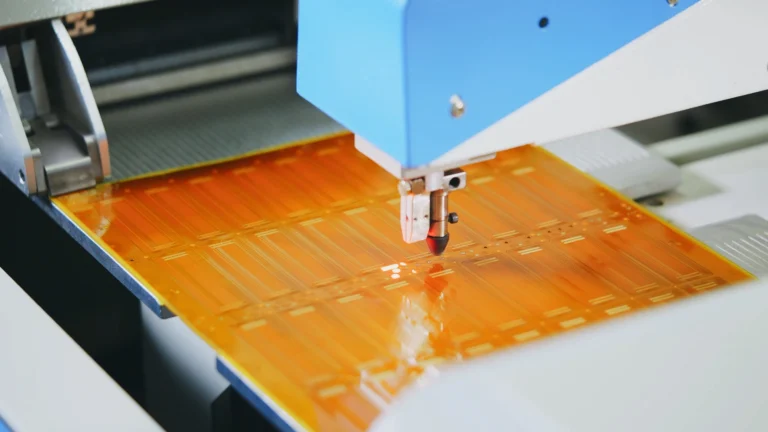

Modern electronics face a critical engineering challenge: maintaining electrical integrity in circuits that bend, twist, and flex thousands of times. From EV battery systems to medical implants, flexible interconnection technology separates reliable products from field failures—demanding sophisticated material selection, advanced design methodologies, and manufacturing expertise. #flexible interconnection