Rapid Prototyping Success: How Material Choices Cut Flexible PCB Development Time in Half

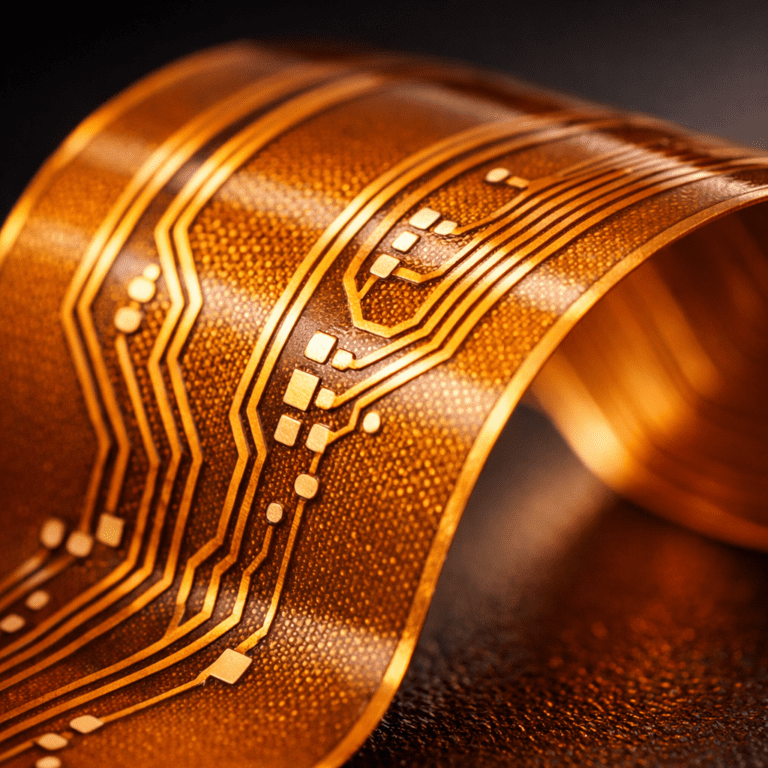

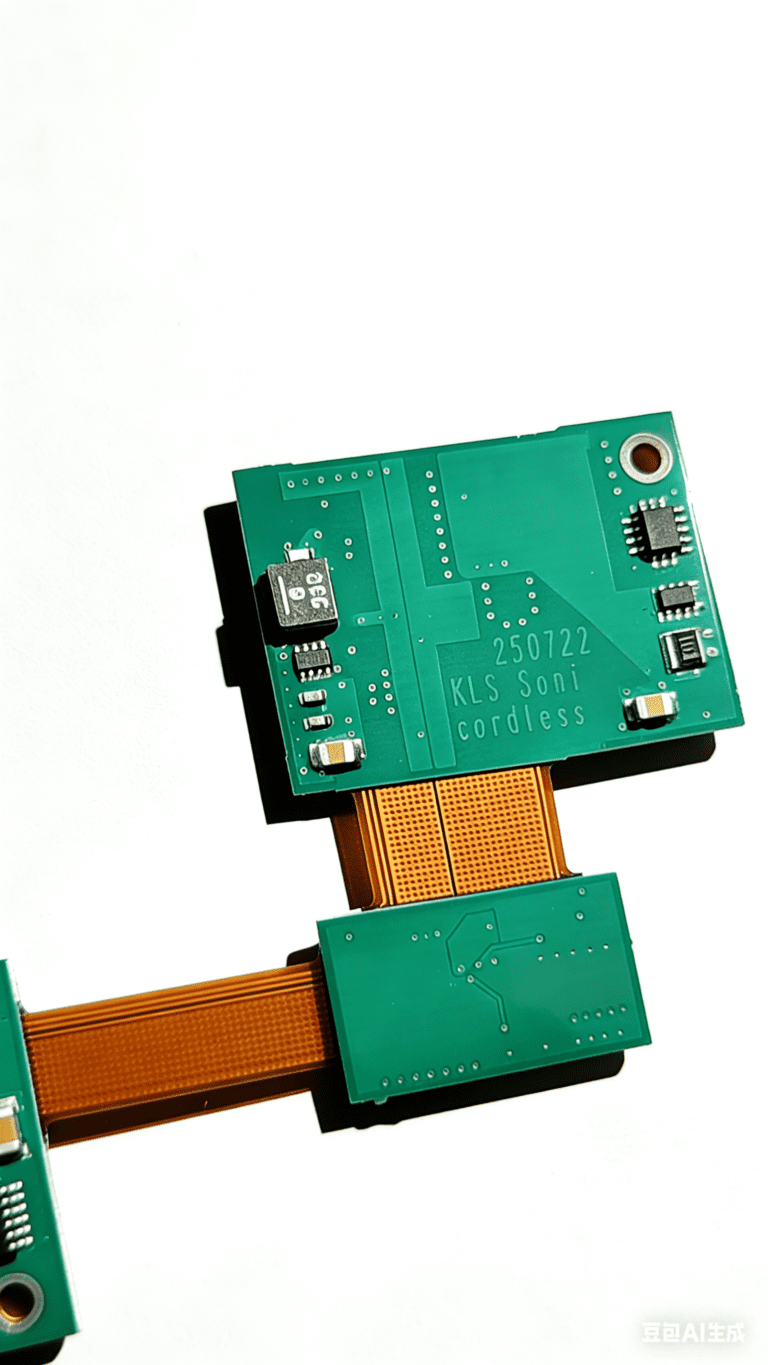

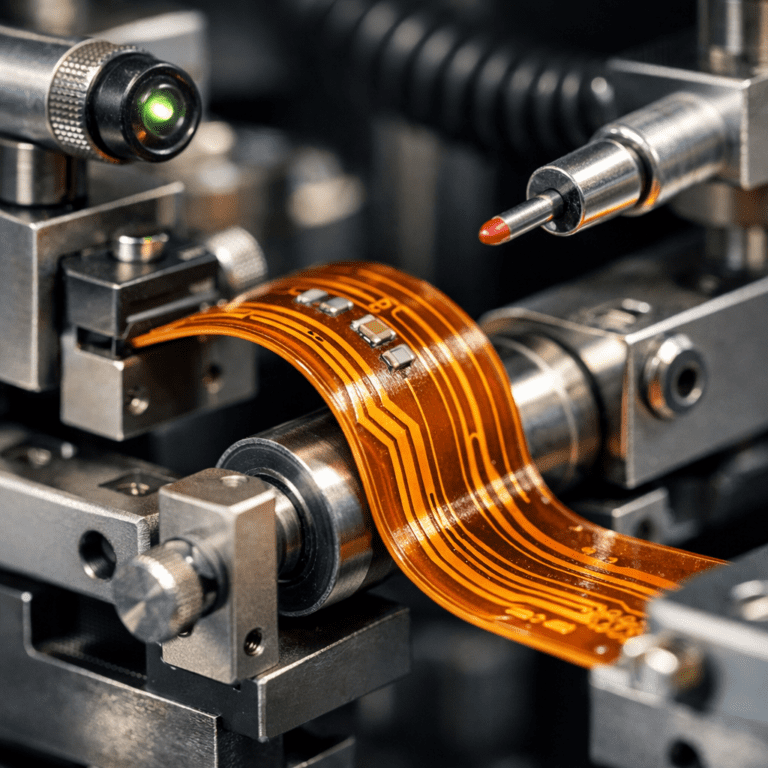

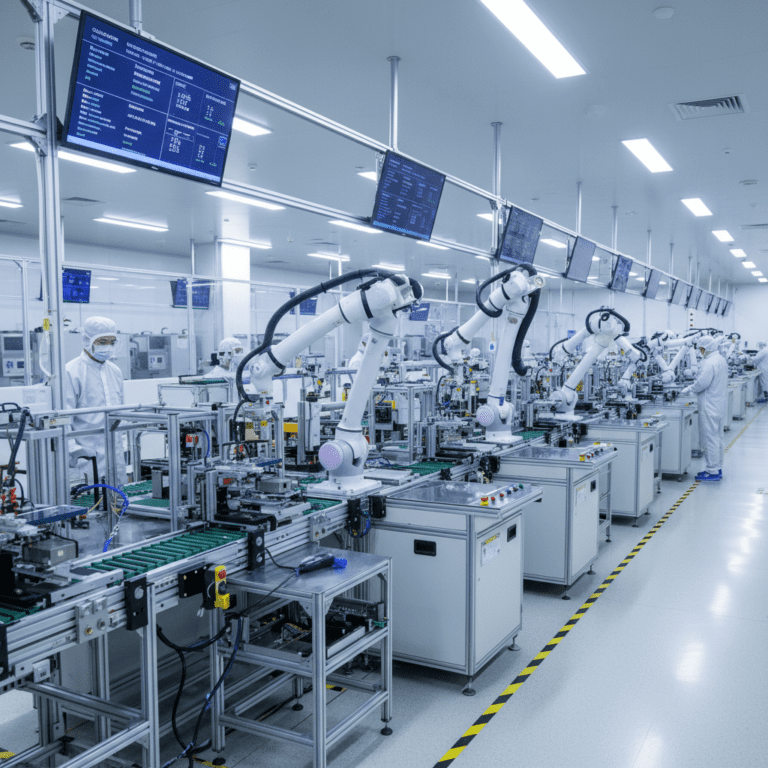

Smart material selection in flexible PCB development isn’t just about specs—it’s about slashing prototyping cycles. When engineers align substrate choices with application demands upfront, they eliminate costly redesigns and achieve working prototypes in half the time. Partner with experts who deliver both material knowledge and manufacturing speed. #Rapid Prototyping