In 2023, a major automotive manufacturer recalled thousands of electric vehicles due to interconnection failures in their battery management systems. The root cause? Traditional rigid circuit boards couldn’t withstand the constant vibration and thermal cycling inherent in EV operation. This incident highlights a critical but often overlooked challenge in modern electronics: flexible interconnection technology isn’t just about making circuits bendable—it’s about maintaining electrical integrity while materials stretch, twist, and deform thousands of times over a product’s lifetime.

Flexible interconnections represent the nervous system of next-generation flexible electronics. From smartwatches that conform to your wrist to medical implants that move with your body, these technologies enable designs impossible with traditional rigid PCBs. Yet behind every successful flexible device lies a complex web of engineering decisions about materials, architecture, and manufacturing processes. Understanding these fundamentals separates products that perform reliably from those that fail in the field.

The Core Engineering Challenge: Maintaining Performance Through Motion

The fundamental challenge in flexible interconnection design centers on a seemingly simple question: how do you maintain consistent electrical performance when the physical medium carrying signals constantly changes shape?

When a copper trace on a flexible substrate bends, it experiences mechanical stress that can alter its resistance, create microcracks, or even cause complete failure. A smartwatch flex circuit might bend 100,000 times during normal use. An automotive sensor in an EV battery pack endures continuous vibration across temperature ranges from -40°C to 125°C. Medical implants must function flawlessly while flexing with body movement for years without maintenance.

Traditional rigid PCB design rules don’t apply here. A trace width that works perfectly on FR-4 might crack after a few dozen bending cycles on polyimide. The challenge multiplies when you consider that modern flexible circuits often carry not just power and simple signals, but high-speed data, requiring careful management of impedance and signal integrity even as the board flexes.

Engineers address these challenges through three primary approaches: innovative trace architectures, advanced material selection, and sophisticated mechanical design.

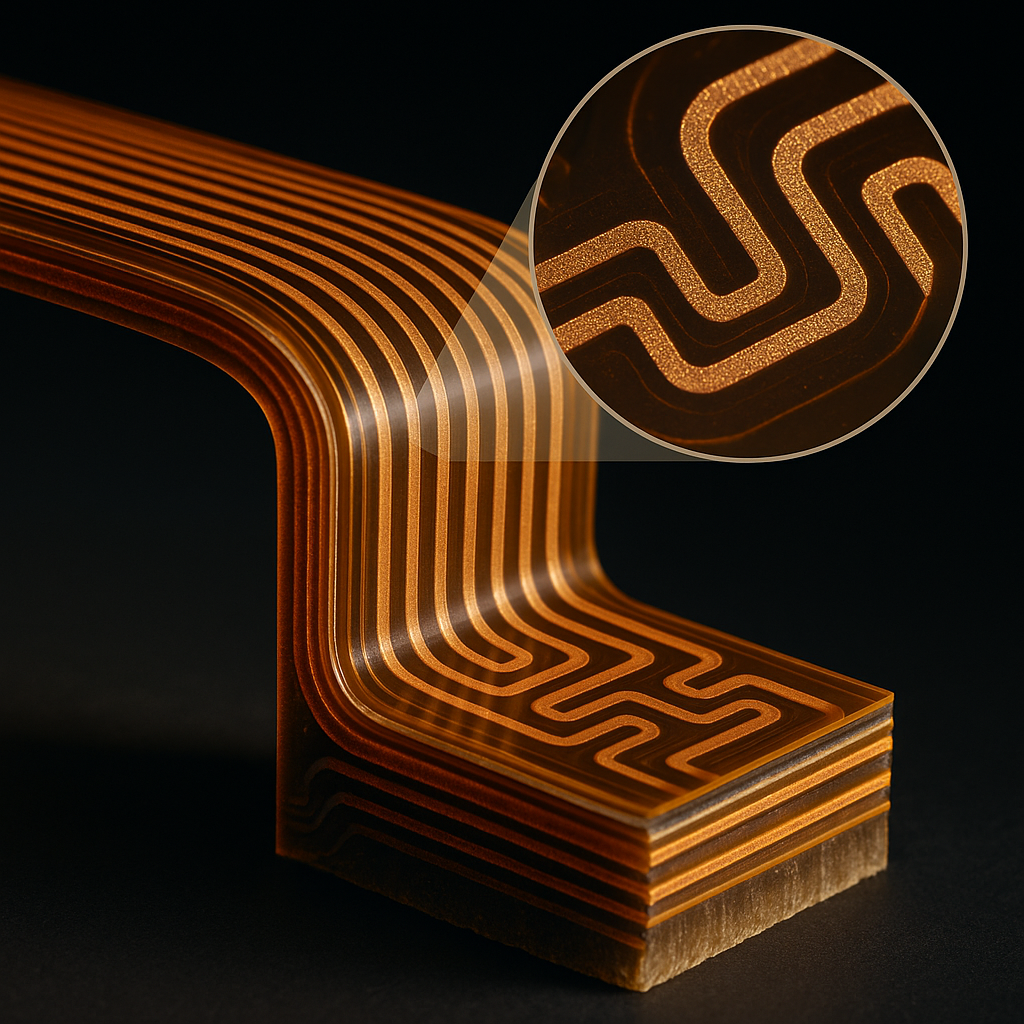

Serpentine trace patterns represent one of the most effective architectural solutions. Instead of routing traces in straight lines, designers create meandering patterns that absorb mechanical stress through geometry. When the substrate bends, these patterns stretch and compress without subjecting the copper to breaking strain. The trade-off? Serpentine traces occupy more board space and can introduce signal integrity concerns at high frequencies. At FlexPlus, our design teams work closely with customers to optimize serpentine geometries—balancing mechanical reliability against electrical performance requirements specific to each application.

Liquid metal interconnects offer a radical alternative for applications requiring extreme flexibility. Gallium-based alloys remain liquid at room temperature and can stretch far beyond the limits of solid conductors. Early research applications in wearable sensors have demonstrated promising results. However, liquid metal interconnects introduce their own challenges: containment within flexible substrates, potential leakage, and integration with standard manufacturing processes remain active research areas.

Conductive polymer materials provide a middle ground between rigid copper traces and liquid metals. These materials combine reasonable conductivity with inherent flexibility, though they typically can’t match copper’s electrical performance. They find applications in specialized areas like textile-integrated circuits and ultra-flexible sensors where some electrical performance can be traded for mechanical advantages.

Material selection extends beyond the conductors themselves. The substrate—typically polyimide chosen for its excellent thermal and mechanical properties—must be selected carefully based on the application’s flexibility requirements, operating temperature range, and expected cycle count. At FlexPlus, we maintain relationships with leading material suppliers globally, ensuring our customers have access to the latest substrate innovations while our 20+ years of experience guides material selection for optimal performance.

Emerging Technologies Reshaping Flexible Interconnection

The field of flexible interconnection is advancing rapidly, driven by demanding applications in consumer electronics, automotive, and medical devices. Two technologies stand out for their transformative potential: 3D interconnects and rigid-flex integration.

Three-dimensional interconnects represent a paradigm shift from traditional planar flexible circuits. Instead of confining all connections to a flat plane, 3D interconnects route signals through the thickness of the substrate or create vertical structures that connect multiple flexible layers. This approach dramatically increases routing density and enables more compact device designs.

The manufacturing implications are significant. Creating reliable vertical interconnections in flexible substrates requires precise via formation and plating processes. Traditional rigid PCB via technologies don’t translate directly to flexible materials, which expand and contract differently than FR-4. Advanced laser drilling systems coupled with specialized electroplating processes enable reliable 3D interconnects, but process control becomes critical. A via that performs flawlessly when flat might fail after a few dozen bending cycles if the plating stress isn’t properly managed.

At FlexPlus, our state-of-the-art facility incorporates advanced laser systems capable of creating micro-vias down to 0.05mm diameter—enabling high-density 3D interconnect designs while maintaining the mechanical integrity necessary for flexible applications. Our engineering team provides comprehensive design feedback to help customers optimize 3D via placement for both electrical performance and mechanical reliability.

Rigid-flex integration solves a different problem: many devices need flexibility in some areas while requiring rigid mounting zones for components, connectors, or mechanical attachment points. Traditional approaches used separate rigid and flexible PCBs connected by cables or connectors—introducing potential failure points and consuming valuable space.

Modern rigid-flex technology eliminates these separations by manufacturing rigid and flexible sections as a single integrated assembly. The manufacturing process sequences precisely controlled lamination cycles, creating rigid areas where multiple layers are bonded together and flexible areas where only essential layers remain. The transition zones between rigid and flexible sections require careful engineering—abrupt thickness changes create stress concentrations that can lead to delamination or cracking.

The benefits extend beyond just eliminating connectors. Rigid-flex designs can reduce device size by up to 60% compared to traditional approaches while improving reliability by eliminating 87% of interconnection points—each connector or cable represents a potential failure mode. For medical devices requiring ISO 13485 certification or automotive electronics needing IATF 16949 compliance, this reliability improvement directly translates to better field performance and lower warranty costs.

Scalable fabrication methods increasingly determine which flexible interconnect technologies succeed commercially. Roll-to-roll processing—where circuits are manufactured on continuous flexible substrates wound on large rollers—offers significant cost advantages for high-volume production. This approach works particularly well for simpler circuit designs and long, narrow formats common in applications like LED lighting strips or automotive wiring harnesses.

However, roll-to-roll processing has limitations. Complex multilayer designs, rigid-flex constructions, and circuits requiring tight dimensional tolerances often require sheet-based processing where individual panels are manufactured separately. Understanding these manufacturing implications during the design phase prevents costly redesigns when moving from prototype to production. FlexPlus maintains both roll-to-roll and sheet processing capabilities, enabling us to select the optimal manufacturing approach based on each design’s specific requirements.

Application Spectrum: Where Flexible Interconnection Creates Value

The true measure of any technology lies in its practical applications. Flexible interconnection technology has moved far beyond early applications in simple consumer electronics, now addressing critical challenges across multiple industries with stringent reliability and certification requirements.

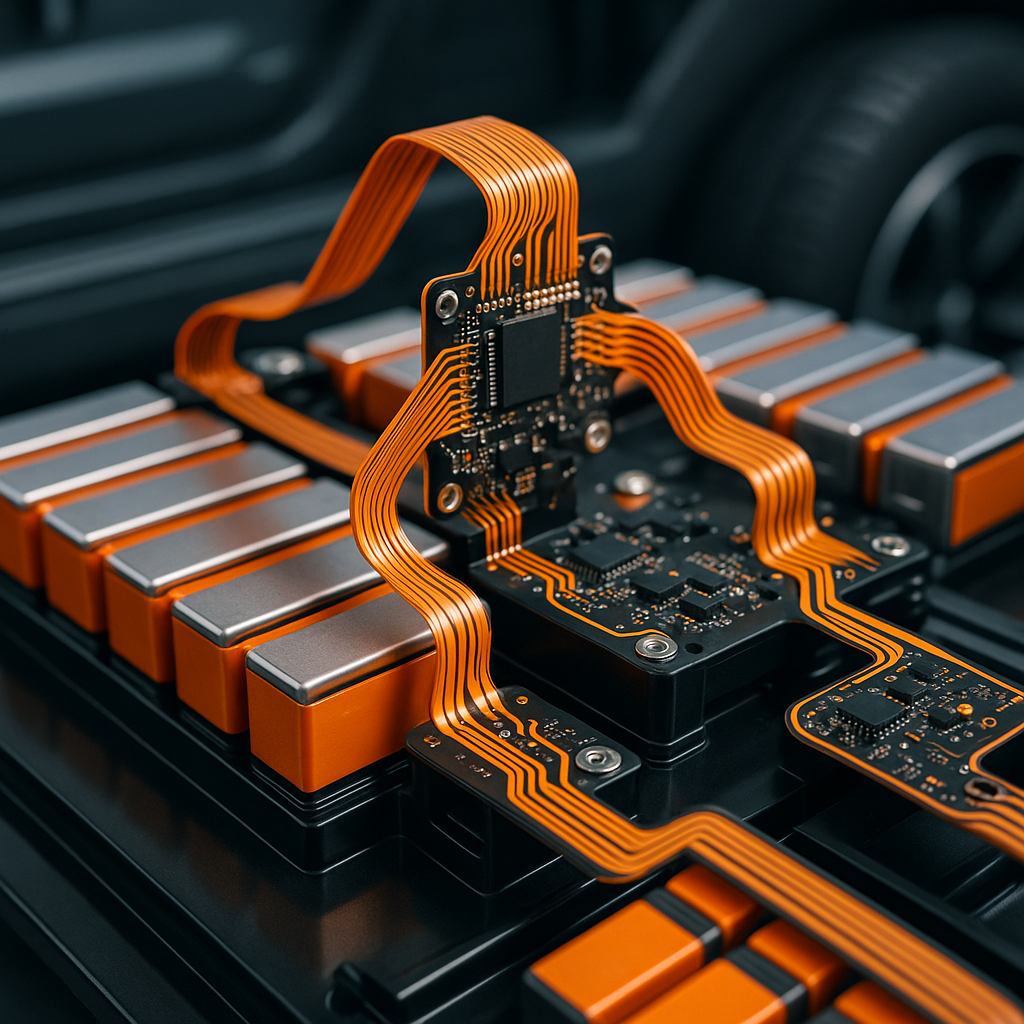

Automotive electronics, particularly in electric vehicles, represent one of the most demanding application areas. Battery management systems require flexible circuits that can withstand continuous vibration, wide temperature excursions, and exposure to automotive fluids while maintaining precise voltage and temperature monitoring for hundreds of individual cells. A single interconnection failure could lead to thermal runaway—a catastrophic safety issue.

These circuits typically employ specialized polyimide substrates rated for 150°C continuous operation, copper weights ranging from 1oz to 2oz to handle high currents, and carefully engineered stress relief features at connection points. The circuits must meet IATF 16949 quality standards and undergo rigorous qualification testing including temperature cycling, vibration testing, and accelerated life testing. FlexPlus’s automotive-certified facility produces flexible circuits for major EV manufacturers and Tier 1 suppliers, with our engineering team providing crucial design support to ensure manufacturability while meeting stringent automotive requirements.

Medical device applications present different but equally challenging requirements. A cardiac monitor must flex with body movement while reliably transmitting biosignals. An implantable device might need to function flawlessly for a decade inside the human body. Beyond electrical and mechanical performance, medical flexible circuits must meet biocompatibility requirements and undergo ISO 13485-certified manufacturing processes.

Recent innovations in flexible interconnection technology are enabling entirely new classes of medical devices. Ultra-thin flexible circuits—down to 25 microns in some applications—can be integrated into bandages or worn directly on skin with minimal discomfort. Our advanced flexible substrate COB (Chip-on-Board) technology enables direct die attachment to flexible circuits, creating complete miniaturized electronic systems that conform to complex body contours. This integration reduces overall system thickness while improving reliability by eliminating traditional component packaging and connection points.

Consumer electronics continue to drive flexible interconnection innovation, though the requirements differ from industrial applications. Smartphones contain dozens of flexible circuits connecting displays, cameras, antennas, and other subsystems within impossibly thin form factors. Wearable devices like smartwatches and fitness trackers demand circuits that can flex thousands of times daily while maintaining signal integrity for sensors and wireless communication.

The consumer electronics industry’s rapid product cycles and cost pressures create unique challenges. Designs must be optimized for high-volume manufacturing while incorporating the latest component technologies. FlexPlus’s comprehensive design support—from initial concept review through DFM analysis and prototype iteration—helps consumer electronics companies navigate these challenges, reducing time-to-market while ensuring designs transition smoothly to mass production.

Aerospace applications push flexible interconnection technology to its limits. Circuits must function across extreme temperature ranges, survive vibration and shock loads during launch or combat maneuvers, and maintain reliability without maintenance for years. The stakes are particularly high—a flexible circuit failure in a satellite’s solar array deployment mechanism or an aircraft’s flight control system could result in mission loss or safety hazards.

These applications typically require additional qualification testing beyond standard industrial requirements: outgassing testing for vacuum compatibility, radiation tolerance verification, and extensive lot-to-lot traceability. The additional requirements translate to higher costs, but the reliability improvements justify the investment for mission-critical applications.

Design Optimization: Tools and Methodologies

Creating successful flexible interconnect designs requires more than just understanding materials and manufacturing processes. Engineers need sophisticated tools and proven methodologies to optimize layouts, ensure signal integrity, and validate mechanical reliability before committing to production.

Simulation and modeling have become indispensable for flexible circuit design. Unlike rigid PCBs where trace geometry remains constant, flexible circuits must be analyzed across their full range of motion. Electromagnetic simulation tools can predict how impedance changes as a circuit flexes—critical for high-speed digital signals or RF applications. Mechanical finite element analysis helps identify stress concentrations and predict fatigue life under cyclic loading.

However, simulation accuracy depends heavily on accurate material models and boundary conditions. The mechanical properties of multilayer flexible stackups—with alternating layers of polyimide, adhesive, and copper—don’t always match simple material databases. At FlexPlus, we maintain an extensive material characterization database built over 20+ years of production experience, enabling our customers to simulate designs with confidence that results will correlate to manufactured hardware.

Design for Manufacturing (DFM) analysis catches potential production issues before they cause delays or quality problems. Trace spacing that looks acceptable on a CAD drawing might violate manufacturing tolerances when accounting for registration tolerances across multiple lamination cycles. Via aspect ratios that work fine in rigid PCBs might be unreliable in flexible substrates. Pad sizes adequate for components on rigid boards might not provide sufficient adhesion strength when the substrate flexes.

FlexPlus’s comprehensive DFMEA (Design Failure Mode and Effects Analysis) process systematically reviews designs for manufacturability issues. Our production engineers work directly with customers to identify potential problems and recommend optimizations. This collaborative approach—enabled by our direct manufacturer model rather than a broker relationship—reduces prototype iteration cycles and accelerates time-to-market.

Signal integrity considerations become more complex in flexible designs. A high-speed differential pair that maintains excellent impedance matching on a rigid board might see impedance variations as the flexible substrate bends, potentially causing signal degradation. Ground reference planes in flexible circuits must be carefully designed to provide return current paths without creating mechanical stress concentrations.

Recent advances in stackup design and materials have improved high-speed performance of flexible circuits. Low-loss polyimide materials reduce signal attenuation at multi-gigahertz frequencies. Controlled impedance specifications—achievable through precise material thickness control and trace geometry—enable reliable high-speed data transmission even in flexible applications. Our technical team provides detailed impedance modeling and optimization recommendations to ensure signal integrity requirements are met across the full range of mechanical flexing.

Future Directions: Sustainability and Advanced Materials

The flexible interconnection field continues advancing rapidly, driven by emerging applications and evolving material technologies. Two trends stand out for their potential to reshape the industry: sustainability initiatives and novel conductor materials.

Sustainable manufacturing practices are becoming increasingly important as electronics companies face pressure to reduce environmental impact. Traditional flexible circuit manufacturing involves numerous chemical processes—copper electroplating, photoresist development, and surface treatments—each generating waste streams requiring careful management. FlexPlus’s ISO 14001 environmental certification demonstrates our commitment to minimizing environmental impact while maintaining production quality.

Emerging sustainable alternatives include additive manufacturing approaches like printed electronics that deposit conductive inks only where needed, eliminating etching waste. Recyclable substrate materials and lead-free surface finishes reduce long-term environmental impact. However, these technologies must mature to match the reliability and performance of established processes before widespread adoption in demanding applications like automotive or medical devices.

Advanced conductor materials promise performance improvements beyond traditional copper. Graphene—a single-atom-thick carbon sheet—offers excellent electrical conductivity combined with exceptional mechanical flexibility. MXenes (a class of two-dimensional materials) provide similar benefits with easier processing. These materials remain primarily in research laboratories today, but early results suggest they could enable flexible circuits that bend to smaller radii, withstand more flexing cycles, and operate at higher frequencies than current technologies allow.

The path from laboratory demonstration to production-qualified manufacturing involves significant challenges. Material suppliers must achieve consistent quality at scale. Manufacturing equipment and processes must be developed and validated. Qualification testing must demonstrate reliability under real-world conditions. This progression typically requires years of development, but the potential benefits justify the investment for applications where current materials reach their limits.

FlexPlus maintains close relationships with material suppliers and research institutions globally, tracking emerging technologies and evaluating their potential application in production environments. Our advanced R&D capabilities enable us to quickly evaluate new materials and processes when customers need solutions beyond current industry capabilities.

Conclusion: Engineering Partnership for Complex Challenges

Flexible interconnection technology has matured from a niche specialty to a critical enabler of modern electronics across industries from consumer devices to mission-critical automotive and medical applications. Yet the engineering challenges remain formidable—maintaining electrical performance through mechanical deformation, ensuring reliability over product lifetimes measured in years or millions of flex cycles, and manufacturing complex designs at production volumes with consistent quality.

Success requires more than just manufacturing capability—it demands deep materials knowledge, sophisticated design tools, comprehensive testing and validation, and close collaboration between design teams and production engineers. Whether you’re developing next-generation wearable sensors, high-reliability automotive electronics, or innovative medical devices, understanding flexible interconnection fundamentals and partnering with experienced manufacturers transforms these challenges into competitive advantages.

The flexible circuits enabling tomorrow’s innovations are being designed and manufactured today. The question isn’t whether flexible interconnection technology will continue advancing—it’s whether your products will benefit from these advances through careful engineering and manufacturing partnerships that turn complex challenges into reliable, high-performance solutions.