The electronics industry is witnessing a quiet revolution. Across factory floors from Silicon Valley to Shenzhen, engineers are abandoning traditional rigid circuit boards in favor of something more sophisticated: rigid with flexible PCB technology. This isn’t just another trend—it’s a fundamental shift in how we design and manufacture electronic devices.

Walk into any modern electric vehicle assembly line, peek inside the latest medical imaging device, or examine the guts of a cutting-edge drone, and you’ll notice something different. Gone are the bulky connector assemblies and multiple separate boards linked by wire harnesses. Instead, you’ll find elegant circuit solutions that bend, fold, and adapt to complex three-dimensional spaces while maintaining the structural integrity needed for reliable performance.

The numbers tell the story. The PCB market is experiencing explosive growth, with a compound annual growth rate of 14.7% between 2023 and 2030. But it’s not just about growth—it’s about transformation. Engineers aren’t simply making more circuit boards; they’re reimagining what circuit boards can be.

Understanding Rigid-Flex PCB Architecture

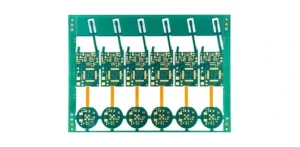

At its core, a rigid with flexible PCB combines two distinct technologies into one integrated solution. Think of it as the best of both worlds: rigid sections provide stable mounting surfaces for components and connectors, while flexible sections allow the board to bend, fold, or flex into configurations that would be impossible with traditional rigid boards.

The architecture is more sophisticated than it might first appear. A typical rigid-flex board construction consists of multiple layers of flexible polyimide substrate laminated together with rigid FR4 sections. The flexible portions typically use polyimide films ranging from 25 to 125 microns in thickness, while the rigid sections follow standard PCB construction with fiberglass-reinforced epoxy laminate.

For electric vehicle manufacturers, this architecture solves a critical challenge. Modern EVs require electronics in increasingly tight spaces—behind dashboard displays, within door panels, around battery management systems. These space-constrained applications benefit from folding electronics design strategies that maximize functionality while minimizing volume. A rigid with flexible PCB can snake through these confined areas while providing solid mounting points for heavy components like power management chips or connector assemblies.

Medical device companies have discovered similar advantages. In portable ultrasound equipment or wearable health monitors, space comes at a premium. Rigid-flex technology allows designers to create compact devices that were previously impossible. The rigid sections house sensitive processors and memory chips, while flexible portions wrap around curved surfaces or fold to fit within small enclosures.

Telecommunications equipment manufacturers use rigid-flex boards in optical transceiver modules, where the technology enables high-density component placement while managing the complex routing required for high-speed signals. The flexible sections handle the dynamic flexing that occurs during installation and operation, while rigid areas provide the dimensional stability critical for optical alignment.

The Compelling Advantages Driving Adoption

Space efficiency stands as perhaps the most obvious benefit. By eliminating connectors and reducing the need for multiple separate boards, rigid-flex designs can reduce overall assembly volume by 40% to 60% compared to traditional approaches. For smartphone manufacturers racing to pack more features into slimmer devices, this space savings directly translates to competitive advantage.

But the benefits extend far beyond miniaturization. Weight reduction matters enormously in aerospace applications and drone manufacturing. Every gram counts when you’re trying to extend flight time or increase payload capacity. Rigid-flex boards weigh significantly less than equivalent assemblies using multiple rigid boards connected by cables and connectors.

Reliability improvements prove even more significant. Traditional assemblies fail most often at connector interfaces—the points where separate boards connect to each other or to cable harnesses. Each connector represents a potential failure point, vulnerable to vibration, thermal cycling, and simple wear. Rigid-flex designs eliminate many of these connections, directly improving overall system reliability.

One aerospace manufacturer reported a 35% reduction in field failures after switching from traditional multi-board assemblies to integrated rigid-flex solutions. The elimination of approximately 20 connector pairs per assembly removed that many potential failure modes.

For industrial control systems operating in harsh environments—high vibration, extreme temperatures, chemical exposure—this reliability advantage becomes critical. The fewer mechanical connections in a system, the fewer opportunities for failure.

Design versatility offers yet another advantage. Engineers can route flexible sections in three dimensions, creating assemblies that conform to available space rather than forcing product design around rectangular circuit boards. This freedom transforms the design process, allowing product designers to optimize for user experience, thermal management, or structural requirements without being constrained by electronics packaging.

Beauty tech manufacturers have embraced this versatility, creating sleek devices where electronics wrap seamlessly around curved surfaces. Smart helmet designers use rigid-flex boards that follow the helmet’s contour, placing sensors and processors exactly where needed without compromising safety or comfort.

Critical Design Considerations

Designing a successful rigid with flexible PCB requires careful attention to several critical factors. Material selection comes first. The flexible portions typically use polyimide film as the base material due to its excellent flexibility, high-temperature tolerance, and electrical properties. For applications requiring biocompatibility—medical implants or wearable health devices—material choices become even more constrained.

Stack-up configuration demands meticulous planning. The number of layers, their arrangement, and the placement of ground planes all affect both electrical performance and mechanical behavior. Understanding proper stackup design principles becomes essential for optimizing your rigid-flex architecture. A typical rigid-flex design might use a four-layer flexible section (signal-ground-ground-signal) transitioning to an eight-layer rigid section where component density increases.

Bend radius emerges as a critical parameter. Every flexible circuit has a minimum bend radius—bend it tighter and you risk copper fracture. Dynamic applications, where the flex section moves repeatedly, require larger bend radii than static applications where the board flexes only during assembly. The minimum dynamic bend radius is typically 10 times the board thickness, while static applications might safely use 6 times thickness.

Trace routing requires special consideration in flexible areas. Sharp corners concentrate stress and should be avoided. Instead, designers use curved traces with generous radii, following proven flex PCB layout techniques that prevent premature failures. Trace width and spacing also affect flexibility—wider traces are stiffer. Staggering traces on different layers prevents creating stiff sections where traces on multiple layers align.

For AR wearables and AI glasses requiring ultra-thin profiles, these design considerations become even more demanding. The entire assembly might need to flex within a 3mm radius while maintaining signal integrity for high-speed data transmission. This requires advanced simulation and careful material selection.

Industrial automation systems present different challenges. These applications might not require tight bending, but they demand robust designs that withstand vibration and thermal cycling over years of operation. Here, reinforcement materials, proper layer transitions, and strain relief features become paramount.

Mastering Transition Zones

The transition zone—where rigid sections meet flexible sections—represents the most challenging aspect of rigid-flex design. Engineers must master flex-rigid interface engineering to prevent catastrophic failures at these critical junctions. This area experiences concentrated stress and requires careful engineering to ensure reliability.

Best practices start with understanding the stress distribution. When a rigid-flex board bends, stress concentrates at the rigid-flex interface. The rigid section wants to remain flat, while the flexible section wants to bend. This creates shearing forces that can delaminate layers or crack conductors.

Successful designs incorporate several strategies to manage this stress. First, use gradual transitions rather than abrupt changes in stiffness. This might involve stepping down the layer count before entering the flexible section, or using partially stiffened areas to create a mechanical buffer.

Second, design the flex area to extend beyond where bending actually occurs. If your assembly requires a 90-degree fold, don’t place the rigid-flex interface exactly at the fold line. Instead, extend the flexible section so bending occurs away from the transition zone.

Third, consider using teardrop-shaped pads where traces transition from rigid to flexible sections. This geometry distributes stress more evenly than rectangular pads, reducing the likelihood of trace separation.

These principles apply across industries. In drone manufacturing, where weight and reliability both matter intensely, proper transition zone design can mean the difference between a successful product and field failures. The vibration and thermal cycling experienced during flight create demanding conditions that expose any weakness in the rigid-flex interface.

Smart helmet manufacturers for F1 racing face similar challenges, but with the added complexity of impact resistance. The rigid-flex assembly must survive not just normal operation but also the violent accelerations of a crash. This requires extensive testing and validation of transition zone designs.

Real-World Applications Driving Innovation

The proof of rigid-flex technology’s value lies in its real-world applications. In the low-altitude airspace industry, companies developing electric vertical takeoff and landing (eVTOL) vehicles face unique challenges. These aircraft require sophisticated avionics in extremely weight-sensitive packages. Rigid-flex boards enable the integration of flight control systems, navigation electronics, and communication systems in assemblies that would be impossible with traditional approaches.

One eVTOL manufacturer reduced their avionics assembly weight by 2.3 kilograms by switching to rigid-flex technology—a meaningful improvement in an industry where every kilogram affects range and payload capacity. Beyond weight savings, the integrated design improved reliability by eliminating 47 connectors from the system.

Beauty tech represents another frontier where rigid with flexible PCB technology shines. Modern beauty devices integrate sophisticated electronics—LED arrays for light therapy, ultrasonic transducers, temperature sensors, and wireless communication—all within ergonomically curved packages that fit comfortably in the user’s hand. Rigid-flex boards make these designs possible, conforming to the device’s shape while providing stable mounting for components.

Medical device manufacturers have found rigid-flex technology essential for advancing portable and implantable devices, particularly those requiring biocompatible materials that meet stringent safety standards. Consider a wearable cardiac monitor that must wrap comfortably around the patient’s chest while housing processing electronics, wireless communication, and multiple sensors. The rigid sections provide structural support and stable mounting for the processor and battery, while flexible sections allow the device to conform to the body’s contour.

Telecommunications companies use rigid-flex boards extensively in optical transceiver modules. These devices must route high-speed differential pairs while managing the complex three-dimensional geometry where optical and electrical interfaces meet. The rigid sections provide precise dimensional control for optical alignment, while flexible sections handle the routing between different planes.

The Path Forward

The shift toward rigid with flexible PCB technology reflects broader trends in electronics design. As devices become smaller, more capable, and more integrated, traditional design approaches reach their limits. Rigid-flex technology provides a path forward, enabling designs that would be impossible with conventional approaches.

This evolution aligns perfectly with the philosophy driving innovation in flexible circuit manufacturing. Success requires not just technical capability but a commitment to partnership with customers, deep expertise in both design and manufacturing, and the quality systems to ensure consistent results.

The future belongs to companies that can combine certified excellence with innovation. ISO 13485 certification ensures that medical device manufacturers receive boards meeting stringent biocompatibility and quality requirements. IATF 16949 certification provides the automotive industry with confidence that boards will survive the demanding conditions of vehicle operation. IPC-6013 compliance ensures that boards meet industry standards for design and manufacture.

But certification alone isn’t enough. True leadership requires pushing boundaries—developing ultra-thin designs for next-generation wearables, creating heat dissipation solutions for high-power applications, advancing COB integration technologies that combine bare die placement directly onto flexible substrates for ultimate miniaturization.

As engineers continue pushing the boundaries of what’s possible in electronic design, rigid with flexible PCB technology will play an increasingly central role. The question isn’t whether to adopt this technology, but how quickly your organization can master it. Those who embrace rigid-flex design early will find themselves with significant competitive advantages: smaller products, higher reliability, reduced assembly costs, and greater design freedom.

The revolution in circuit board technology isn’t coming—it’s already here. Top engineers aren’t ditching traditional boards on a whim; they’re responding to the fundamental requirements of next-generation electronic products. Rigid with flexible PCB technology provides the foundation for innovation across industries, from electric vehicles to medical devices, from telecommunications to aerospace. The only question is whether you’ll lead this transition or follow.