In today’s rapidly evolving electronics landscape, flexible PCBs have become critical components in everything from medical devices to electric vehicles. The quality, reliability, and performance of your end product depend significantly on the flexible PCB manufacturer you choose. Making the wrong choice can lead to costly delays, performance issues, or even complete product failure.

Whether you’re developing cutting-edge medical devices requiring ISO 13485 certification or automotive electronics components needing IATF 16949 compliance, selecting the right flexible PCB manufacturing partner is a decision that deserves careful consideration.

1. What Are Your Specific Capabilities Relative to My Project Requirements?

Before approaching any flexible PCB manufacturer, you need a clear understanding of your project requirements. This includes technical specifications like:

- Circuit complexity and layer count

- Size dimensions and thickness constraints

- Flexibility requirements (static flex vs. dynamic flex)

- Environmental conditions the PCB must withstand

- Production volume needs (prototype to mass production)

- Budget constraints

A reputable manufacturer like Flex Plus will thoroughly evaluate your specifications against their capabilities. For instance, if your project requires ultra-thin designs with precise 2/2mil line width/spacing or multilayer flexible PCBs up to 8 layers, you need a manufacturer with the appropriate technical expertise and equipment.

Advanced manufacturers can help optimize your design for manufacturability, potentially saving costs while maintaining functionality. For example, Flex Plus engineers routinely provide design feedback to optimize flexible PCB designs for both performance and manufacturing yield.

When discussing capabilities, ask for specific examples of similar projects they’ve completed. An experienced flexible PCB manufacturer should be able to showcase their expertise through case studies or samples.

2. Are You a Local or International Manufacturer, and How Will This Impact Our Collaboration?

The geographical location of your flexible PCB manufacturer affects several aspects of your project:

Communication: Working with international manufacturers may introduce time zone challenges and potential language barriers. Ask how they handle communication and if they have dedicated account managers who speak your language.

Logistics: International shipping adds time and complexity to your supply chain—understand their shipping methods, transit times, and import procedures. Flex Plus enhances sustainability with an environmentally friendly wood trays that strictly adheres to European standards, featuring 0 – formaldehyde, zero pollution, and packaging fully labeled as passing all required certifications.

Cost structure: While international manufacturers often offer competitive pricing, factor in additional costs like customs duties, shipping, and potential delays.

Intellectual property protection: Ensure the manufacturer has robust IP protection measures, especially for sensitive designs.

Companies like Flex Plus have developed systems to minimize international collaboration challenges. With extensive experience serving over 2,500 customers across North America, Europe, Japan, Taiwan, and Southeast Asia, they’ve established efficient communication protocols and logistics solutions that bridge geographical gaps.

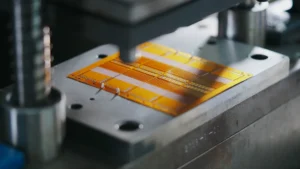

3. What Manufacturing Equipment and Technology Do You Use?

The quality and capabilities of a flexible PCB manufacturer are directly related to their equipment and technology investments. Ask specific questions about:

- The age and specifications of their production equipment

- Capabilities for fine-line processing (minimum line width/spacing)

- Advanced technologies like laser drilling for microvias

- Inspection equipment (AOI, flying probe testers, etc.)

- In-Circuit Testing (ICT): Software directs a “bed-of-nails” fixture, connectors or probes to check on board components, shorts/opens, resistance, and capacitance on assembled boards.

- Process controls and automation level

Leading manufacturers invest continuously in advanced equipment. For instance, Flex Plus utilizes state-of-the-art production lines capable of sheet-by-sheet processing, with specialized equipment for ultra-thin flexible PCB production down to overall 0.025 mm thickness.

Ask about their quality control systems and how they verify PCB performance at each manufacturing stage. Advanced inspection technologies like automated optical inspection (AOI) and electrical testing ensure that defects are caught before the PCBs reach your production line.

4. What Certifications and Standards Do You Comply With?

Certifications are critical indicators of a manufacturer’s commitment to quality and their ability to serve specific industries. Depending on your application, certain certifications are non-negotiable:

ISO 9001: The baseline quality management system certification

ISO 13485: Essential for medical device applications

IATF 16949: Required for automotive electronics components

IPC-6013: The specific standard for flexible printed boards

UL Certification: Important for safety-critical applications

ISO 14001: Demonstrates environmental management commitment

A manufacturer’s certifications reveal much about their quality processes and industry focus. For example, Flex Plus maintains full compliance with ISO 9001, ISO 13485, IATF 16949, IPC-6013, UL, and ISO 14001 certifications, enabling them to serve customers across medical, automotive, industrial, and consumer electronics sectors with consistent quality and regulatory compliance.

Ask to see current certification documentation and inquire about their internal audit processes to maintain compliance with these standards.

5. What Production Volumes Can You Handle and How Quickly?

Understanding a manufacturer’s production capacity is essential, particularly if you anticipate scaling from prototypes to high-volume production. Ask about:

- Minimum order quantities for prototypes

- Maximum production capacity for large-volume orders

- Typical lead times for prototypes and production runs

- Ability to scale production quickly when needed

- Capacity utilization and potential for rush orders

Manufacturers with flexible production capabilities can better accommodate your needs throughout the product lifecycle. For example, Flex Plus offers quick turn prototyping (within one week) while also maintaining high-volume production lines capable of meeting substantial order quantities. Their manufacturing facility spans over 8,000 square meters, their monthly production capabilities are 15,000 square meters, providing ample capacity for projects of all sizes.

Also inquire about their approach to prototyping and whether they offer specialized quick-turn services for faster development cycles. The ability to rapidly iterate through prototypes can significantly accelerate your product development timeline.

6. What Materials Do You Recommend for My Application?

Material selection dramatically impacts the performance, reliability, and cost of flexible PCBs. A knowledgeable manufacturer should provide guidance on:

- Substrate materials (polyimide thickness options)

- Copper foil types and thicknesses

- Adhesive systems for multilayer constructions

- Coverlay or solder mask options

- Specialized materials for unique requirements

Experienced manufacturers like Flex Plus work with a range of high-quality materials, from standard polyimide substrates to specialized options like TPU circuits for biocompatible applications. They should explain how different materials affect flexibility, durability, and electrical performance based on your specific application.

Ask about their material sourcing practices and quality control procedures. High-quality manufacturers maintain strict supplier qualification processes and incoming material inspection to ensure consistency.

For specialized applications, inquire about their experience with unique materials. For example, Flex Plus has developed expertise in TPU circuits with stretchable and biocompatible properties for medical applications, offering sizes from 10-600mm and various copper foil options from 18-70μm.

7. Can You Provide References and Examples of Similar Projects?

7. Can You Provide References and Examples of Similar Projects?

Perhaps the most telling indicator of a manufacturer’s capabilities is their track record with similar projects. Request:

- References from customers in your industry

- Case studies of similar applications

- Samples demonstrating relevant capabilities

- Details about their longest customer relationships

Quality manufacturers are proud of their work and willing to share success stories. While confidentiality agreements may limit some disclosures, experienced manufacturers like Flex Plus can provide anonymized case studies or general references to demonstrate their expertise in your application area.

Ask specifically about their experience with challenging aspects of your project. For instance, if you need long flexible PCBs, ask about their experience with extended-length circuits—Flex Plus can produce flexible PCBs up to 3 meters by sheer sheet by sheet processing.

Red Flags to Watch For

When evaluating responses from flexible PCB manufacturers, be alert to these warning signs:

Vague answers about capabilities: If a manufacturer can’t provide specific details about their processes and equipment, they may be a broker rather than a true manufacturer.

Reluctance to discuss quality metrics: Quality-focused manufacturers track and share metrics like yield rates and defect levels.

No design support or feedback: The best manufacturers offer design for manufacturing guidance to improve yields and reduce costs.

Unrealistic promises: Be wary of manufacturers promising extremely short lead times without explaining how they’ll achieve them.

Poor communication: If communication is difficult during the quoting process, it will likely worsen during production.

A trustworthy manufacturer like Flex Plus emphasizes transparent communication and realistic expectations while demonstrating their commitment to quality through certifications and proven processes.

Consider Visiting the Manufacturing Facility

When possible, visiting the manufacturing facility provides invaluable insights that can’t be conveyed through email or video calls. During a visit, you can:

- Observe cleanliness and organization

- Meet the engineering and production teams

- Verify equipment capabilities firsthand

- Review quality control processes

- Discuss your project with technical experts

Many reputable manufacturers welcome customer visits and use them as opportunities to showcase their capabilities. Flex Plus maintains an open-door policy for potential customers to tour their 8,000+ square meter factory and witness their advanced production lines and quality control systems in action.

Request Samples and Prototypes

Before committing to a large production run, request samples or prototype runs to evaluate quality. This gives you the opportunity to:

- Verify manufacturing precision

- Test performance in your application

- Evaluate finishing quality

- Assess flexibility and durability

- Check compatibility with your assembly process

Quality-focused manufacturers like Flex Plus offer specialized prototype services with accelerated timelines, understanding that these early samples are crucial for your development process. Their quick-turn prototyping capability can deliver samples within one week, including DFM analysis and material consultation.

Conclusion: Make an Informed Decision

Selecting the right flexible PCB manufacturer is a critical decision that affects your product’s quality, timeline, and cost. By asking these seven crucial questions, you’ll gain deeper insights into each manufacturer’s capabilities and determine if they’re the right partner for your project.

Look for manufacturers like Flex Plus who offer the complete package: certified excellence through ISO 13485 and IATF 16949, advanced technical capabilities, transparent communication, comprehensive design support, and proven experience with similar applications. Their commitment to quality, innovation, and customer service demonstrates the kind of partnership that leads to successful flexible PCB projects.

By thoroughly evaluating potential manufacturing partners before committing to your next flexible PCB project, you’ll minimize risks and position your product for success in increasingly competitive markets.