In today’s fast-paced electronics industry, the difference between a market-leading device and an also-ran often comes down to the smallest components. Among these critical elements, flexible printed circuit boards (FPCBs) have emerged as game-changers for products requiring compact design, durability, and reliability. However, not all FPCB manufacturers are created equal, and choosing the right partner can significantly impact your product’s performance, time-to-market, and overall success.

Whether you’re developing next-generation electric vehicle control systems, miniaturized medical devices, or cutting-edge consumer electronics, the FPCB manufacturer you select will fundamentally influence your product’s functionality, reliability, and competitive advantage. This article examines five critical differences among FPCB manufacturers that can make or break your electronic product development journey.

1. Technical Capabilities: The Foundation of Excellence

The technical prowess of an FPCB manufacturer represents perhaps the most significant differentiator in determining your project’s success. This encompasses several key areas:

Design Proficiency

Leading FPCB manufacturers employ dedicated teams of experienced engineers who specialize in flexible circuit design. These professionals understand the unique challenges of working with flexible substrates and can optimize designs for manufacturability, reliability, and performance.

Top manufacturers are proficient in addressing special requirements such as controlled impedance, EMI shielding, and high-speed signal integrity. They can accurately translate your electrical and mechanical requirements into manufacturable designs that maintain signal integrity even when bent or folded in demanding applications.

For medical device companies developing implantable products or automotive electronics suppliers building IATF 16949-certified components, this expertise is invaluable. The best FPCB partners don’t just fabricate your design – they enhance it through design for manufacturing (DFM) analysis that identifies potential issues before production begins.

Material Selection Expertise

Material choice significantly impacts FPCB performance, especially in harsh environments. Premium manufacturers offer comprehensive knowledge of substrate materials beyond basic polyimide, including:

- High-temperature materials for automotive under-hood applications

- Biocompatible materials for medical devices

- Specialized laminates for high-frequency applications

- TPU circuits for stretchable applications

A manufacturer with deep material expertise can recommend the optimal substrate, copper weight, adhesive system, and surface finish for your specific application requirements. This knowledge prevents costly redesigns and ensures your product performs as expected in real-world conditions.

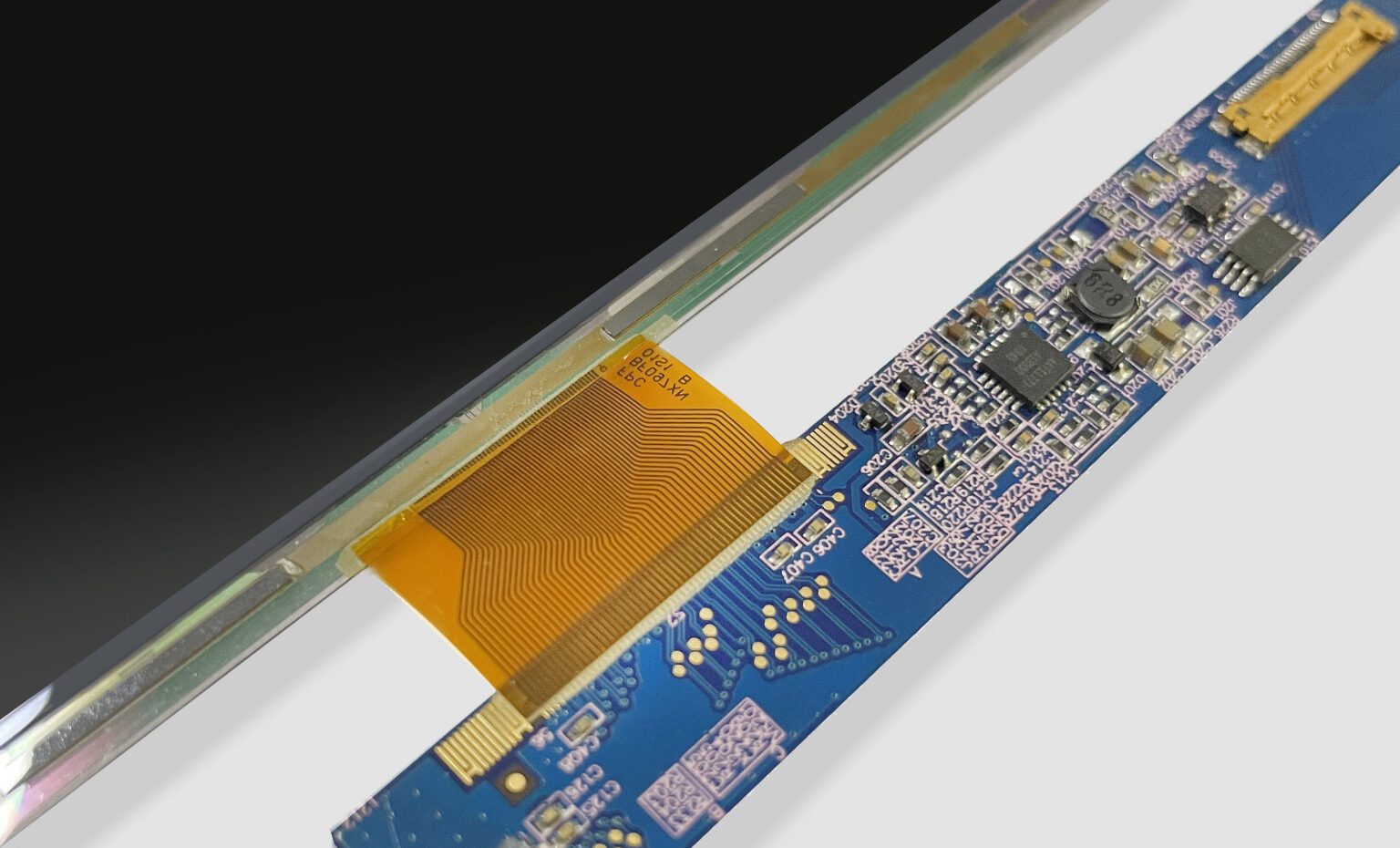

Advanced Production Techniques

The manufacturing capabilities gap between average and exceptional FPCB producers is substantial. Industry leaders invest in advanced equipment that enables:

- Fine-line capabilities (down to 2/2mil line width/spacing)

- Multilayer constructions (up to 8+ layers)

- Long flex circuits (up to 3 meters in specialized facilities)

- HDI (High-Density Interconnect) flex circuits

- Rigid-flex combinations that eliminate connectors

For telecommunications equipment manufacturers and smartphone companies, these advanced capabilities enable the creation of increasingly complex circuits in ever-smaller form factors.

Prototyping and Testing Processes

Speed-to-market often determines product success. Elite FPCB manufacturers offer quick-turn prototyping services, sometimes delivering functional prototypes within a week. They maintain dedicated prototyping lines separate from mass production to ensure rapid iteration without disrupting regular production schedules.

Moreover, comprehensive testing capabilities – including automated optical inspection (AOI), electrical testing, bend testing, and environmental simulation – ensure that prototypes and production units meet stringent performance requirements before reaching your assembly line.

2. Quality Control Systems: The Reliability Differentiator

Quality control methodologies represent another crucial distinction between FPCB manufacturers. Top-tier suppliers implement robust systems that go beyond basic inspection to include:

Defect Prevention Strategies

Leading manufacturers employ a preventive approach to quality rather than relying solely on inspection. This includes:

- Statistical Process Control (SPC) to monitor critical parameters in real-time

- Failure Mode and Effects Analysis (FMEA) to anticipate potential issues

- Poka-yoke (mistake-proofing) systems to prevent manufacturing errors

- Advanced vision systems that detect defects invisible to the human eye

These preventive measures result in significantly higher first-pass yields and fewer field failures, which is particularly critical for medical devices requiring ISO 13485 certification.

Yield Optimization Techniques

The economics of FPCB production are heavily influenced by manufacturing yield. Elite manufacturers invest in yield optimization through:

- Automated material handling to reduce contamination

- Climate-controlled clean rooms for sensitive processes

- Precise process parameter control

- Continuous improvement systems that analyze defect patterns

These investments translate to more consistent quality and better value, especially in high-volume applications like consumer electronics.

Regulatory Compliance Standards

For many industries, regulatory compliance isn’t optional. Superior FPCB manufacturers maintain multiple certifications including:

- ISO 9001 quality management systems

- ISO 13485 for medical device components

- IATF 16949 for automotive applications

- IPC-6013 standards for flexible circuit performance

- UL certification for safety-critical applications

- ISO 14001 for environmental management

These certifications aren’t just paperwork; they represent disciplined management systems that ensure consistent quality and compliance with industry standards. For international electronics companies operating across multiple markets, working with a fully certified manufacturer simplifies regulatory approval processes.

The importance of quality systems becomes apparent when considering the consequences of FPCB failures. In medical devices, a failed flexible circuit can compromise patient safety. In automotive applications, it could lead to recall campaigns costing millions. For consumer products, it might result in warranty claims and brand damage. Premium FPCB manufacturers build quality systems specifically to mitigate these risks.

3. Manufacturing Control: In-House vs. Outsourced

Another key differentiator is the level of manufacturing control maintained by the FPCB supplier. This aspect is often overlooked but can significantly impact product quality and delivery reliability:

Fully Integrated Manufacturers

The most reliable FPCB partners are true manufacturers with comprehensive in-house capabilities including:

- Complete production lines from raw material preparation to final testing

- Dedicated facilities with specialized equipment

- Direct control over all critical processes

- Engineering teams on the production floor

This contrasts with trading companies or brokers who may represent themselves as manufacturers but actually outsource production, adding layers of communication, cost, and potential quality issues.

Vertical Integration Benefits

Vertically integrated FPCB manufacturers offer significant advantages:

- Faster problem resolution when issues arise

- More consistent quality control

- Greater flexibility for design modifications

- Better cost control and transparency

- Shorter lead times, especially for complex designs

For R&D engineers requiring rapid prototyping or OEM partners seeking certified solutions, this direct control over the manufacturing process provides invaluable peace of mind.

4. Engineering Support: Beyond Basic Manufacturing

The level of engineering support provided represents another critical difference between FPCB suppliers:

Design Collaboration

Top FPCB manufacturers act as true engineering partners, offering:

- Design review and optimization services

- Material selection guidance

- Stack-up recommendations for multilayer designs

- Signal integrity analysis for high-speed applications

- 3D modeling support for complex rigid-flex combinations

This collaborative approach is particularly valuable for precision electronics designers pushing the boundaries of miniaturization and functionality.

Problem-Solving Capabilities

When challenges arise – as they inevitably do in complex electronic products – the technical problem-solving capabilities of your FPCB manufacturer become invaluable. Leading manufacturers offer:

- Failure analysis laboratories

- Materials characterization capabilities

- Process engineering expertise

- Root cause analysis methodologies

These resources can mean the difference between a quick solution and a prolonged development delay.

5. Communication and Service: The Human Factor

While technical capabilities form the foundation of FPCB manufacturing excellence, the human elements of communication and service often determine the actual experience of working with a manufacturer:

Responsive Communication

The best FPCB partners provide:

- Clear points of contact with technical expertise

- Prompt responses to inquiries and concerns

- Transparent updates on project status

- Proactive notification of potential issues

This level of communication is particularly important when working across time zones or language barriers, as is often the case with international projects.

Flexible Adaptation to Changing Needs

Market requirements often shift during product development. Superior FPCB manufacturers demonstrate flexibility through:

- Accommodation of design changes

- Scalable production capabilities

- Adjustable delivery schedules

- Willingness to explore novel solutions

This adaptability can be crucial for companies in fast-moving markets like consumer electronics or emerging technologies.

Making Your Decision: Selecting the Right FPCB Manufacturing Partner

When evaluating potential FPCB manufacturers for your next electronic product, consider these five differentiators carefully. The right partner will offer not just competitive pricing but the technical capabilities, quality systems, manufacturing control, engineering support, and responsive service needed to ensure your product’s success.

Look beyond immediate cost to consider total value, including reliability, time-to-market advantages, and reduced risk of failures or redesigns. For complex applications in medical devices, electric vehicles, telecommunications equipment, or precision consumer electronics, these factors often outweigh basic per-unit pricing in determining the true cost of ownership.

The electronics industry continues to demand increasingly sophisticated flexible circuit solutions as products become smaller, more capable, and more durable. By partnering with an FPCB manufacturer that demonstrates excellence across these five critical differentiators, you position your next electronic product for success in even the most competitive markets.

In this evolving landscape of electronic innovation, companies like Flex Plus (Xiamen) Co., Ltd. stand out by offering a unique combination of certified manufacturing excellence, advanced technical capabilities, and innovative approaches to flexible circuit challenges. As you evaluate FPCB manufacturers for your next project, look for a partner whose philosophy aligns with your needs for quality, innovation, and reliable performance – factors that will ultimately determine whether your next electronic product thrives in the marketplace.