When a medical device malfunctions mid-procedure or an electric vehicle’s control system fails on the highway, the consequences extend far beyond warranty claims. These catastrophic failures often trace back to a single root cause: inadequate testing during flexible PCB manufacturing. For companies scaling from prototype to mass production, understanding and implementing robust testing standards isn’t just about compliance—it’s about protecting your brand reputation and ensuring end-user safety.

The stakes are particularly high in high-volume production environments. A single defect that slips through quality control can multiply into thousands of field failures, resulting in costly recalls, regulatory scrutiny, and damaged customer relationships. This is why industry-leading manufacturers like FlexPlus prioritize comprehensive quality assurance protocols backed by internationally recognized testing standards.

The Foundation: Key Testing Standards That Define Reliability

The flexible PCB manufacturing process relies on several critical standards to ensure consistent quality across manufacturers. The most important among these are IPC-2223, IPC-TM-650, and IPC-6013—each serving a distinct but complementary role in the quality assurance ecosystem.

IPC-2223 serves as the sectional design standard specifically for flexible and rigid-flex printed boards. Unlike generic PCB standards, IPC-2223 addresses the unique challenges of flexible circuits, including layer stack-up configurations, minimum bend radius requirements, and via placement in dynamic flex regions. This standard helps designers and manufacturers speak the same language when discussing flexible circuit specifications.

For manufacturers serving medical device companies or automotive suppliers, IPC-2223 compliance isn’t optional—it’s the foundation upon which all other quality measures are built. The standard defines critical parameters like how to calculate minimum bend radius as a multiplier of flex thickness, accounting for variables like copper weight and adhesive thickness. A flex circuit designed without these guidelines may pass initial inspection but fail catastrophically after repeated flexing in real-world applications.

IPC-TM-650 represents a comprehensive test methods manual that provides detailed procedures for evaluating material properties and circuit performance. This isn’t a design standard but rather a cookbook of proven test methodologies. Each test method within IPC-TM-650 receives a unique identifier—for example, 2.4.9 for peel strength testing or 2.5.7.2 for dielectric withstanding voltage (HiPot) testing.

IPC-6013 focuses specifically on qualification and performance specifications for flexible and rigid-flex printed boards. This standard establishes three distinct classes of circuits—Class 1, 2, and 3—each with escalating requirements for inspection, testing, and performance. Understanding which class applies to your application determines the intensity of quality control measures required.

At FlexPlus, our 20+ years of experience has taught us that standards compliance isn’t about checking boxes—it’s about building systematic processes that catch potential failures before they reach production lines. Our ISO 9001, ISO 13485, and IATF 16949 certifications reflect this commitment to process excellence across diverse industries.

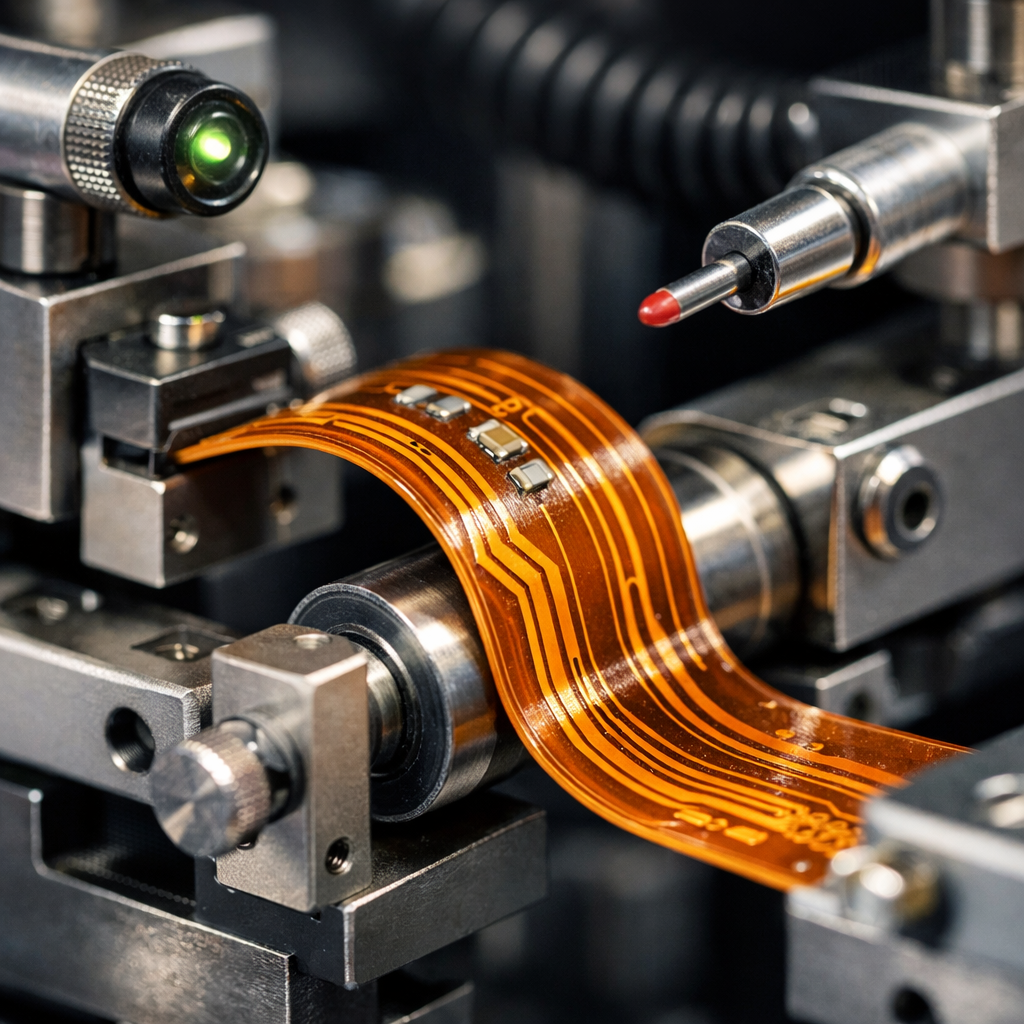

Critical Tests That Prevent Mechanical Failures

Within the IPC-TM-650 manual, several specific tests directly correlate with preventing field failures in flex circuits. These tests evaluate the fundamental mechanical properties that determine whether a flexible PCB will survive its intended application.

Peel strength testing (IPC-TM-650 2.4.9) measures the bond strength between copper foil and the flexible dielectric substrate. This test uses a 90-degree peel configuration with strictly defined sample dimensions—typically 50.8 × 50.8mm—to ensure reproducible results. The test subject pulls the copper foil away from the substrate at a controlled rate while measuring the force required.

Industry standards require minimum room-temperature peel strength of 1.5 N/mm for reliable circuits. However, the test becomes more demanding when evaluating high-temperature performance. After exposure to temperatures like 288°C (simulating soldering processes), the peel strength must still exceed 0.7 N/mm. Circuits that fail this threshold risk delamination during assembly or field use.

Consider a real-world scenario from the automotive flex PCB industry: A flex circuit connecting sensors in an electric vehicle’s battery management system experienced intermittent failures during thermal cycling tests. Investigation revealed that while room-temperature peel strength met specifications, the adhesive system degraded significantly at elevated temperatures. The manufacturer had skipped high-temperature peel strength verification, assuming room-temperature results were sufficient. This oversight nearly resulted in a costly recall affecting thousands of vehicles.

Bend and flex endurance testing simulates the repeated flexing that circuits experience in applications like smartphone hinges, wearable devices, or robotic arms. The test fixture repeatedly bends the circuit through a specified angle and radius while monitoring for electrical failures. The number of cycles before failure indicates the circuit’s mechanical durability.

IPC-2223 provides guidance on minimum bend radius calculations, but flex endurance testing validates whether the actual design meets real-world requirements. A circuit designed for a consumer electronics product might require 100,000 flex cycles, while a medical device application might demand 1,000,000 cycles or more.

FlexPlus‘s experience with wearable medical devices highlights why this testing matters. A client developing a continuous glucose monitoring patch initially specified a bend radius based on theoretical calculations. However, flex endurance testing revealed that the adhesive system failed after only 50,000 cycles—far short of the required 500,000 cycles for the device’s intended lifespan. By identifying this issue during qualification testing rather than after product launch, we helped the client reformulate the material stack-up and achieve reliable performance.

Dielectric testing (IPC-TM-650 2.5.7.2) verifies the insulation integrity between conductors and layers. This HiPot test applies high voltage between circuit layers to ensure the dielectric material can withstand electrical stress without breakdown. For high-voltage applications like EV power distribution or industrial motor controls, dielectric strength directly impacts safety.

The test typically applies voltages ranging from 250V to several thousand volts, depending on the circuit’s operating voltage and safety class. Any current leakage or breakdown during testing indicates compromised insulation—a defect that could cause catastrophic failures in the field.

Thermal Testing: Assessing Reliability Under Environmental Stress

Temperature extremes represent one of the most common causes of flex PCB failures in applications ranging from automotive electronics to aerospace systems. Two distinct testing methodologies—temperature cycling and thermal shock—evaluate thermal reliability through different mechanisms.

Temperature cycling subjects circuits to gradual temperature transitions between hot and cold extremes, typically ranging from -55°C to +125°C or beyond, depending on application requirements. Each complete cycle might take 30 minutes to several hours, with the circuit dwelling at each temperature extreme before transitioning. The test evaluates how materials with different coefficients of thermal expansion (CTE) interact over hundreds or thousands of cycles.

This testing methodology excels at revealing fatigue failures that develop gradually. The repeated expansion and contraction of copper traces, vias, and substrate materials creates mechanical stress at interfaces. Over time, these stresses can propagate into cracks, particularly at via barrels or in regions where rigid and flexible sections join.

For rigid-flex designs—where FlexPlus offers configurations from 2 to 12 layers—temperature cycling becomes especially critical. The junction between rigid and flexible sections creates a stress concentration point where CTE mismatch is most pronounced. Our experience shows that circuits which pass initial electrical testing may develop intermittent failures after 500-1000 temperature cycles if the design doesn’t properly accommodate these stresses.

Thermal shock testing uses rapid temperature transitions—often changing 100°C or more within seconds—to evaluate material compatibility under extreme thermal stress. Rather than simulating gradual environmental changes, thermal shock replicates scenarios like moving a cold device into a hot environment or the extreme temperature gradients experienced during wave soldering.

The rapid temperature change creates internal stresses within materials that don’t have time to equilibrate thermally. This can reveal adhesion failures between layers, cracking in plated through-holes, or delamination that wouldn’t appear during gentler temperature cycling.

At FlexPlus, we’ve observed that circuits designed for aerospace or military applications—where thermal shock is a genuine operational concern—require different material selections than those intended for consumer electronics. Adhesive systems must maintain bond strength across temperature extremes, and copper weights must be carefully balanced to minimize internal stress without compromising electrical performance.

A telecommunications equipment manufacturer learned this lesson when their optical transceiver modules experienced field failures in data centers. The circuits passed standard temperature cycling tests but failed in environments with aggressive HVAC systems that created rapid temperature swings. Thermal shock testing during qualification would have revealed this vulnerability before product launch.

Comprehensive Quality Assurance Through Advanced Inspection

Mechanical and thermal testing provide critical reliability data, but comprehensive quality assurance requires electrical verification and defect detection across 100% of production units. This is where automated inspection technologies become essential for high-volume manufacturing.

Automated Optical Inspection (AOI) uses high-resolution cameras and sophisticated image processing algorithms to detect surface defects that human inspectors might miss. The system captures detailed images of each circuit and compares them against known-good reference images, identifying issues like:

- Missing or misaligned copper features

- Coverlay registration errors

- Contamination or foreign material

- Improper solder mask application

- Scratches or handling damage

For fine-pitch designs with minimum trace widths of 0.05mm (2mil)—a capability FlexPlus offers for high-density interconnect applications—AOI becomes indispensable. Human visual inspection simply cannot consistently detect defects at this scale across thousands of circuits per day.

Flying Probe Testing provides electrical verification without requiring expensive test fixtures. Two or more independently controlled probes make contact with test points on the circuit, measuring resistance, capacitance, and continuity. This approach offers several advantages for flexible PCB manufacturing:

- No fixture costs make it economical for prototype and low-volume production

- Fast program changes accommodate design iterations

- Can test circuits with irregular shapes or non-standard test point locations

- Provides detailed fault diagnostics for process improvement

However, flying probe testing becomes time-consuming for high-volume production. At FlexPlus, we typically recommend flying probe testing for prototype verification and design validation, transitioning to bed-of-nails fixtures for production volumes exceeding several thousand units per month.

X-ray inspection reveals hidden defects invisible to optical inspection. This technology proves critical for evaluating:

- Via formation and copper plating quality

- Internal layer alignment in multilayer constructions

- Hidden delamination or voids

- Solder joint quality in assembled boards

For medical device manufacturers requiring ISO 13485 compliance, X-ray inspection often becomes a mandatory process step. The ability to detect internal defects non-destructively provides assurance that circuits meet stringent reliability requirements without destroying production units.

FlexPlus‘s investment in X-ray inspection capabilities reflects our commitment to serving industries where hidden defects are unacceptable. A single void in a via barrel might cause intermittent failures that are nearly impossible to diagnose in the field. Catching these defects during manufacturing prevents costly field failures and protects patient safety in medical applications.

Understanding Class-Based Testing Requirements

IPC-6013 establishes three distinct classes of flexible circuits, each with progressively stringent inspection and testing requirements. Understanding which class applies to your application determines the appropriate level of quality assurance investment.

Class 1 circuits serve general electronic products where cosmetic imperfections are acceptable and reliability requirements are moderate. Consumer electronics that aren’t safety-critical often fall into this category. Class 1 inspection allows visual defects that don’t affect functionality, and sampling plans may inspect as few as 10% of production units.

Class 2 circuits represent dedicated service electronic products where extended life and uninterrupted service are desired but not critical. Most commercial applications—including many automotive electronics, telecommunications equipment, and industrial controls—specify Class 2 requirements. Inspection becomes more thorough, with higher sampling rates and tighter acceptability criteria.

Class 3 circuits support high-reliability applications where continued performance is critical and equipment downtime cannot be tolerated. Medical implantable devices, aerospace avionics, and military systems typically require Class 3 qualification. At this level:

- 100% inspection of critical features becomes mandatory

- Acceptance criteria exclude most cosmetic defects

- Documentation requirements intensify significantly

- Supplier qualification processes become extensive

FlexPlus‘s IATF 16949 certification for automotive applications and ISO 13485 certification for medical devices demonstrates our capability to meet Class 3 requirements when applications demand it. However, we also work with clients to rightsize quality requirements—overspending on Class 3 controls for Class 2 applications unnecessarily increases costs without improving reliability.

A common mistake in high-volume production is applying uniform inspection criteria across all circuit areas. IPC-6013 allows reduced inspection in non-critical regions while maintaining intensive scrutiny of critical areas. For example, a flex circuit might require Class 3 inspection at interconnection points and dynamic flex regions while allowing Class 2 criteria for static sections. This targeted approach optimizes quality assurance costs while maintaining reliability where it matters most.

Practical Quality Assurance Workflows

Implementing testing standards effectively requires systematic workflows that integrate inspection and testing throughout the manufacturing process rather than treating quality assurance as a final checkpoint.

Defining acceptance criteria upfront prevents disputes and ensures alignment between customer expectations and manufacturing capabilities. At FlexPlus, we engage clients in Design for Manufacturing (DFM) reviews before production begins. These sessions establish:

- Which IPC class applies to each circuit region

- Critical-to-quality characteristics requiring 100% inspection

- Acceptable quality levels (AQL) for sampling plans

- Test methods and pass/fail criteria for reliability testing

This proactive approach eliminates the frustration of discovering misaligned expectations after production investment.

Maintaining comprehensive test documentation creates traceability required for regulated industries and provides data for process improvement. FlexPlus‘s quality management system captures:

- Incoming material test results

- In-process inspection data at each manufacturing stage

- Final electrical test records

- Environmental and reliability test results for qualification lots

- Non-conformance reports and corrective actions

For medical device manufacturers, this documentation becomes part of the device history record supporting regulatory submissions. For automotive suppliers, it provides evidence of IATF 16949 compliance during customer audits.

Design-for-test strategies build testability into circuit designs from the outset. Simple design choices significantly impact manufacturing quality:

- Including test points at strategic locations enables comprehensive electrical testing

- Designing consistent pad sizes simplifies AOI programming

- Avoiding blind vias in critical signal paths reduces X-ray inspection requirements

- Incorporating visual fiducials improves automated inspection accuracy

FlexPlus‘s engineering team provides DFM feedback identifying testability issues before prototype fabrication. A client designing a rigid-flex circuit for an industrial sensor initially positioned test points in the flexible region where probe access would be difficult. By relocating test points to rigid sections, we enabled reliable electrical testing without risking damage to the flexible circuit during probing.

Process feedback loops complete the quality assurance system by using test data to drive continuous improvement. When defects appear during inspection or testing, root cause analysis determines whether issues stem from:

- Design weaknesses requiring engineering changes

- Material variations requiring supplier corrective action

- Process parameter drift requiring equipment adjustment

- Training gaps requiring operator skill development

At FlexPlus, our 20+ years of manufacturing experience has built institutional knowledge about failure modes and their prevention. When we identify a recurring defect pattern, we don’t just screen out defective units—we modify processes to prevent defect generation. This approach, supported by our ISO 9001 quality management system, drives year-over-year improvements in first-pass yield and reliability.

Conclusion: Building Reliability Into Every Circuit

Preventing field failures in high-volume flexible PCB production requires more than occasional testing—it demands systematic application of industry standards throughout design and manufacturing. The testing standards we’ve explored—IPC-2223 for design guidance, IPC-TM-650 for test methodologies, and IPC-6013 for acceptance criteria—provide the framework for building reliability into every circuit.

Key takeaways for engineering teams scaling to production include:

Combine multiple test methods for comprehensive quality control. Peel strength testing, flex endurance evaluation, thermal cycling, and electrical verification each reveal different potential failure modes. Relying on any single test method creates blind spots where defects can hide.

Match testing intensity to application requirements through appropriate IPC class selection. Class 3 controls aren’t always necessary, but cutting corners on safety-critical applications invites catastrophic consequences. Understanding where your application falls on the reliability spectrum determines the appropriate quality investment.

Invest in design-for-test and design-for-manufacturing collaboration early in development. The most cost-effective time to prevent defects is during design—before tooling investment and production ramp-up. Partnering with manufacturers who provide DFM feedback, like FlexPlus’s engineering team, catches issues when they’re inexpensive to fix.

Build process feedback loops that transform test data into continuous improvement. Testing reveals not just defective units but also opportunities to refine processes, improve yields, and prevent future failures.

At FlexPlus, our commitment to testing standards and quality assurance reflects two decades of experience serving industries where failure isn’t an option. Whether you’re developing medical implantables requiring ISO 13485 compliance, automotive electronics demanding IATF 16949 certification, or consumer products balancing cost and reliability, we bring the expertise to navigate testing requirements and deliver circuits that perform reliably in the field.

The investment in comprehensive quality assurance pays dividends throughout a product’s lifecycle—preventing costly recalls, protecting brand reputation, and ensuring that when your product reaches customers, it works as intended. In high-volume production, there’s no substitute for robust testing standards properly applied.