Flex PCB Manufacturing Capabilities

Technical Specifications & Engineering Support

Explore our comprehensive flexible PCB manufacturing capabilities. From detailed technical specifications to advanced processing techniques, this page serves as your complete technical reference guide for partnering with Flex Plus on your next project.

Flex PCB Manufacturing Capabilities

Technical Specifications & Engineering Support

Explore our comprehensive flexible PCB manufacturing capabilities. From detailed technical specifications to advanced processing techniques, this page serves as your complete technical reference guide for partnering with Flex Plus on your next project.

Comprehensive Manufacturing Capabilities

Detailed technical specifications for flexible and rigid-flex PCB manufacturing

| Capability | Specification |

|---|---|

| Board Type | Single-Sided FPC / Double-Sided FPC / Multilayer FPC (3-8 Layers) / Rigid-Flex PCB (2-12 Layers) / Dual-Access FPC (Bare Back FPC) / Split FPC / Sculptured FPC / TPU Circuit |

| Board Size | Standard length: Up to 1.6 meters Specialized length: Up to 4 meters TPU Circuit: 10-600mm |

| Board Thickness | TPU substrate: 0.15-1.0mm Note: Varies by product type and layer count |

| Ultra-Thin Design | Down to 25 micron with gold plating on Double-Sided Flex PCB |

| Minimum Line Width/Space | 0.05mm / 0.05mm (2mil/2mil) |

| Copper Weight | 18μm – 70μm (½ oz – 2 oz) TPU Circuit: 18-70μm copper foil |

| Base Material | Polyimide (PI) / FR-4 / Thermoplastic Polyurethane (TPU) |

| Max Layer Count | Flexible PCB: 8 layers Rigid-Flex PCB: 12 layers |

| Circuit Layers (TPU) | 1-2 layers |

| Special Features | • Flexible heat dissipation flow channels • Transparent PCB (transparency ≥ 90%) • 3D contour shaping (Sculptured FPC) |

| Lead Time | Standard: Within 1 week Emergency: 3 days |

| Quality Standards | ISO Certifications: ISO 9001 / ISO 13485 / IATF 16949 / ISO 14001 FPC Standards: IPC-6013 (USA) / IPC/JPCA (Japan) / TPCA (Taiwan) Safety: UL Certification |

| Factory Size | 16,000+ square meters |

Comprehensive Manufacturing Capabilities

Detailed technical specifications for flexible and rigid-flex PCB manufacturing

| Capability | Specification |

|---|---|

| Board Type | Single-Sided FPC / Double-Sided FPC / Multilayer FPC (3-8 Layers) / Rigid-Flex PCB (2-12 Layers) / Dual-Access FPC (Bare Back FPC) / Split FPC / Sculptured FPC / TPU Circuit |

| Board Size | Standard length: Up to 1.6 meters Specialized length: Up to 4 meters TPU Circuit: 10-600mm |

| Board Thickness | TPU substrate: 0.15-1.0mm Note: Varies by product type and layer count |

| Ultra-Thin Design | Down to 25 micron with gold plating on Double-Sided Flex PCB |

| Minimum Line Width/Space | 0.05mm / 0.05mm (2mil/2mil) |

| Copper Weight | 18μm – 70μm (½ oz – 2 oz) TPU Circuit: 18-70μm copper foil |

| Base Material | Polyimide (PI) / FR-4 / Thermoplastic Polyurethane (TPU) |

| Max Layer Count | Flexible PCB: 8 layers Rigid-Flex PCB: 12 layers |

| Circuit Layers (TPU) | 1-2 layers |

| Special Features | • Flexible heat dissipation flow channels • Transparent PCB (transparency ≥ 90%) • 3D contour shaping (Sculptured FPC) |

| Lead Time | Standard: Within 1 week Emergency: 3 days |

| Quality Standards | ISO Certifications: ISO 9001 / ISO 13485 / IATF 16949 / ISO 14001 FPC Standards: IPC-6013 (USA) / IPC/JPCA (Japan) / TPCA (Taiwan) Safety: UL Certification |

| Factory Size | 16,000+ square meters |

Need help interpreting these specifications?

Our engineering team can help you determine the optimal configuration for your application. We offer comprehensive DFM analysis (DFMEA), material consultation, and technical feedback to reduce risk and optimize yield.

Need help interpreting these specifications?

Our engineering team can help you determine the optimal configuration for your application. We offer comprehensive DFM analysis (DFMEA), material consultation, and technical feedback to reduce risk and optimize yield.

Advanced Manufacturing Capabilities

What sets our factory apart in flexible PCB manufacturing

Complete In-House Manufacturing Control

End-to-End Production

As a dedicated flex PCB manufacturer, we offer end-to-end control over production, unlike brokers or trading companies. Our 16,000+ square meter facility and advanced equipment ensure precision, quality, and customization for every project.

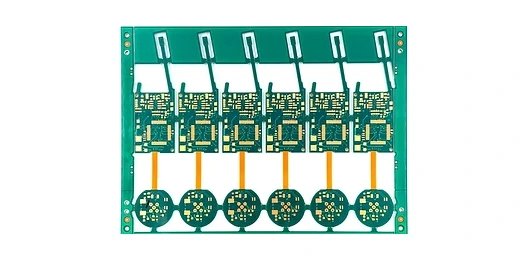

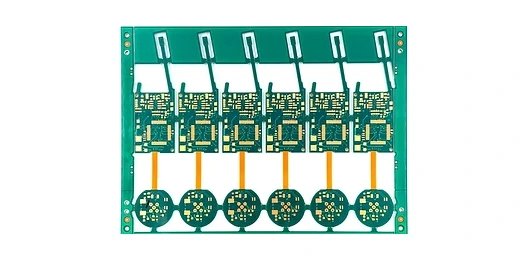

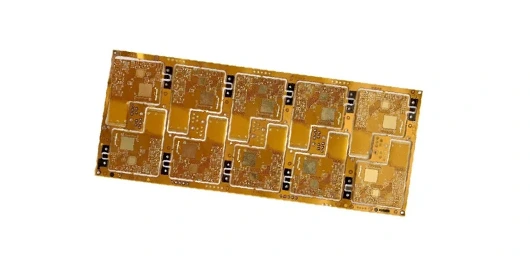

Rigid-Flex PCB Technology

Hybrid Circuit Solutions

Advanced hybrid technology combining rigid PCB sections for component mounting with flexible circuits for dynamic bending. Eliminates connectors and reduces assembly complexity in a single integrated structure.

Applications: Aerospace systems, medical devices, consumer electronics, automotive sensors, military equipment

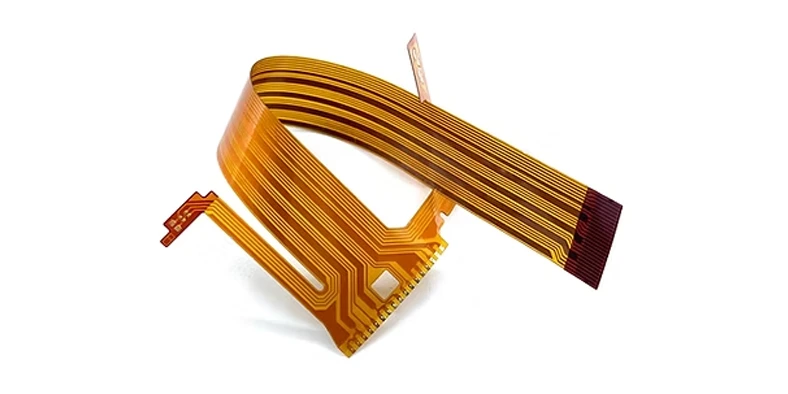

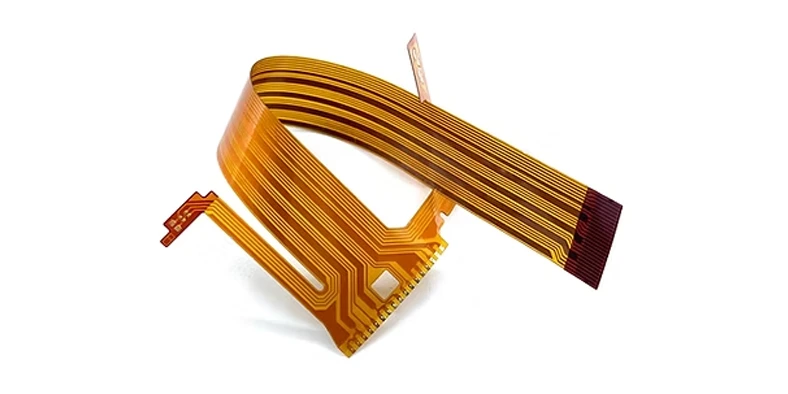

Long-Format Flex PCB Capability

From Ultra-Miniature to 3 Meters

Our dedicated workshops and advanced equipment enable us to produce a wide range of flexible PCBs, from ultra-miniature micro Flex PCBs to long-format designs.

Applications: Automotive harnesses, industrial sensors, LED lighting systems

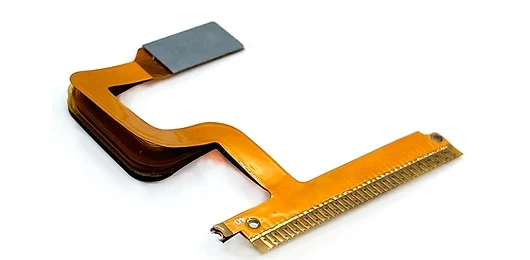

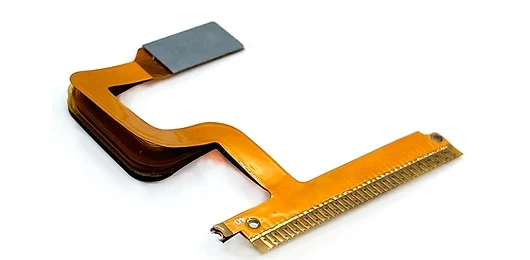

Ultra-Thin Flex Technology

Down to 25 Microns

Advanced R&D capabilities including ultra-thin designs with overall thickness as thin as 25 micron with gold plating on Double Sided Flex PCB.

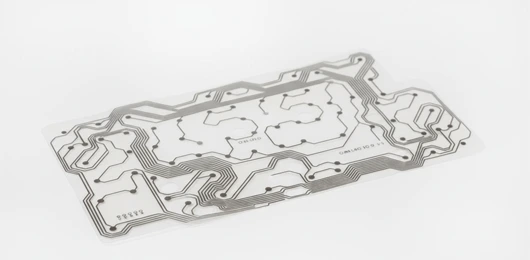

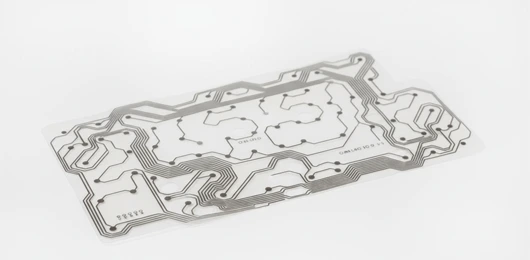

TPU Circuit Innovation

Next-Generation Stretchable Electronics

Breakthrough technology: various types of printing circuits on TPU material (completely printing circuits on TPU) for next-generation applications.

Applications: Wearable devices, medical equipment, beauty tech gadgets

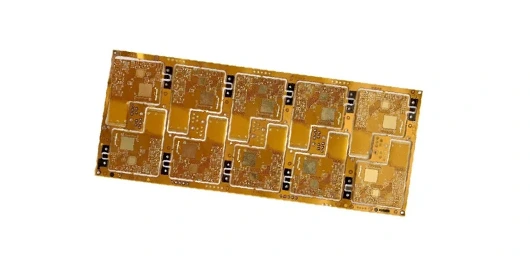

High-Density Interconnect

Precision Manufacturing

Advanced capabilities for high-density interconnect (HDI) designs with minimum line width and spacing of 0.05mm (2mil/2mil).

Thermal Management Solutions

Flexible Heat Dissipation

Pioneering breakthrough technology: flexible heat dissipation flow channels integrated into flex PCB designs.

Transparent PCB Technology

≥90% Light Transmission

Revolutionary transparent PCBs with transparency ≥ 90% for optical and display integration applications.

Advanced Manufacturing Capabilities

What sets our factory apart in flexible PCB manufacturing

Complete In-House Manufacturing Control

End-to-End Production

As a dedicated flex PCB manufacturer, we offer end-to-end control over production, unlike brokers or trading companies. Our 16,000+ square meter facility and advanced equipment ensure precision, quality, and customization for every project.

Rigid-Flex PCB Technology

Hybrid Circuit Solutions

Advanced hybrid technology combining rigid PCB sections for component mounting with flexible circuits for dynamic bending. Eliminates connectors and reduces assembly complexity in a single integrated structure.

Applications: Aerospace systems, medical devices, consumer electronics, automotive sensors, military equipment

Long-Format Flex PCB Capability

From Ultra-Miniature to 3 Meters

Our dedicated workshops and advanced equipment enable us to produce a wide range of flexible PCBs, from ultra-miniature micro Flex PCBs to long-format designs.

Applications: Automotive harnesses, industrial sensors, LED lighting systems

Ultra-Thin Flex Technology

Down to 25 Microns

Advanced R&D capabilities including ultra-thin designs with overall thickness as thin as 25 micron with gold plating on Double Sided Flex PCB.

TPU Circuit Innovation

Next-Generation Stretchable Electronics

Breakthrough technology: various types of printing circuits on TPU material (completely printing circuits on TPU) for next-generation applications.

Applications: Wearable devices, medical equipment, beauty tech gadgets

High-Density Interconnect

Precision Manufacturing

Advanced capabilities for high-density interconnect (HDI) designs with minimum line width and spacing of 0.05mm (2mil/2mil).

Thermal Management Solutions

Flexible Heat Dissipation

Pioneering breakthrough technology: flexible heat dissipation flow channels integrated into flex PCB designs.

Transparent PCB Technology

≥90% Light Transmission

Revolutionary transparent PCBs with transparency ≥ 90% for optical and display integration applications.

Design for Manufacturing (DFM) Support

Comprehensive design support from concept to mass production

DFM Analysis (DFMEA)

Comprehensive Design for Manufacturing analysis to optimize your design:

Material Consultation

Expert guidance on substrate and material selection:

Technical Feedback

Collaborative engineering partnership throughout your project:

Engineering Partnership

Complete support from concept to mass production:

Design for Manufacturing (DFM) Support

Comprehensive design support from concept to mass production

DFM Analysis (DFMEA)

Comprehensive Design for Manufacturing analysis to optimize your design:

Material Consultation

Expert guidance on substrate and material selection:

Technical Feedback

Collaborative engineering partnership throughout your project:

Engineering Partnership

Complete support from concept to mass production:

Material & Substrate Options

Choose the right materials for your application requirements

Flexible Base Materials

| Material | Key Characteristics | Typical Applications |

|---|---|---|

| Polyimide (PI) | High temperature resistance Excellent chemical resistance Superior mechanical properties | Automotive, aerospace, industrial, medical devices |

| FR-4 | Standard rigid substrate Cost-effective Good electrical properties | Rigid-flex combinations, general applications |

| TPU (Thermoplastic Polyurethane) | Stretchable and flexible Biocompatible Chemical resistant | Wearables, medical devices, beauty tech |

Copper Weights Available

Copper Foil Options

- 18μm (½ oz) – Ultra-thin applications

- 35μm (1 oz) – Standard applications

- 70μm (2 oz) – High current applications

Available range: 18-70μm based on your requirements

Need Material Guidance?

Our materials engineering team provides expert recommendations based on:

- Application requirements and environment

- Electrical and thermal specifications

- Mechanical flexibility needs

- Cost optimization opportunities

Material & Substrate Options

Choose the right materials for your application requirements

Flexible Base Materials

| Material | Key Characteristics | Typical Applications |

|---|---|---|

| Polyimide (PI) | High temperature resistance Excellent chemical resistance Superior mechanical properties | Automotive, aerospace, industrial, medical devices |

| FR-4 | Standard rigid substrate Cost-effective Good electrical properties | Rigid-flex combinations, general applications |

| TPU (Thermoplastic Polyurethane) | Stretchable and flexible Biocompatible Chemical resistant | Wearables, medical devices, beauty tech |

Copper Weights Available

Copper Foil Options

- 18μm (½ oz) – Ultra-thin applications

- 35μm (1 oz) – Standard applications

- 70μm (2 oz) – High current applications

Available range: 18-70μm based on your requirements

Need Material Guidance?

Our materials engineering team provides expert recommendations based on:

- Application requirements and environment

- Electrical and thermal specifications

- Mechanical flexibility needs

- Cost optimization opportunities

Material Consultation Service

Not sure which materials are right for your application? Our engineering team offers free material consultation to help you select the optimal substrate, copper weight, and construction for your specific requirements.

Material Consultation Service

Not sure which materials are right for your application? Our engineering team offers free material consultation to help you select the optimal substrate, copper weight, and construction for your specific requirements.

Custom Project Manufacturing

Tailored production solutions for your unique project requirements, from initial prototype to full-scale manufacturing

PROTOTYPING

Small Quantities

Within 1 week

Design testing & validation

QUICK-TURN

Emergency Service

3 days

Fast prototyping & urgent needs

HIGH-VOLUME

Mass Production

Custom schedule

Volume manufacturing

Production Services

Rapid Prototyping

Volume Production

Processing Methods

Full Assembly Services

Custom Project Manufacturing

Tailored production solutions for your unique project requirements, from initial prototype to full-scale manufacturing

PROTOTYPING

Small Quantities

Within 1 week

Design testing & validation

QUICK-TURN

Emergency Service

3 days

Fast prototyping & urgent needs

HIGH-VOLUME

Mass Production

Custom schedule

Volume manufacturing