The electronics industry is experiencing a profound shift toward flexible printed circuit boards (FPCBs), driven by demands for lighter, more compact, and dynamically bendable devices. In automotive, medical, and consumer electronics sectors, engineers increasingly rely on FPCBs to meet design constraints that rigid boards simply cannot address. Yet this transition introduces unique manufacturing challenges, particularly during surface mount technology (SMT) assembly. Unlike their rigid counterparts, flexible substrates move, warp, and respond unpredictably to thermal stress—making component shifting a persistent threat to yield and reliability.

For companies like Flex Plus (Xiamen) Co., Ltd, which has spent over 20 years refining flexible PCB manufacturing processes, the solution lies in two critical areas: specialized fixturing systems and precisely controlled thermal profiling. These techniques transform inherently unstable flexible substrates into reliable platforms for high-density component assembly. Understanding these methodologies is essential for any engineering team transitioning from rigid PCB designs to flexible solutions at production scale.

Understanding Flexible Substrate Characteristics and Material Selection

The foundation of successful SMT assembly for FPCB begins with substrate selection. Polyimide (PI) remains the dominant material choice for flexible circuits due to its exceptional thermal stability, with glass transition temperatures exceeding 300°C. This high-temperature tolerance makes polyimide suitable for multiple reflow cycles without degradation. However, polyimide’s flexibility—its defining advantage—also introduces dimensional instability during handling and thermal processing.

Polyethylene terephthalate (PET) offers a lower-cost alternative for applications not requiring extreme temperature resistance. PET substrates work well for single-layer designs with limited thermal exposure, but their lower melting point restricts reflow temperature windows. For medical wearables and next-generation beauty tech devices, thermoplastic polyurethane (TPU) substrates represent an emerging option. TPU circuits combine biocompatibility with exceptional flexibility, though they demand even more careful thermal management during assembly.

Material selection extends beyond the base substrate. The adhesive layer bonding copper to the flexible dielectric fundamentally impacts both flexibility retention and thermal behavior during reflow. Adhesiveless constructions, where copper is directly deposited onto polyimide, offer superior flexibility and eliminate delamination risks associated with adhesive degradation. However, they typically cost more and require specialized manufacturing capabilities.

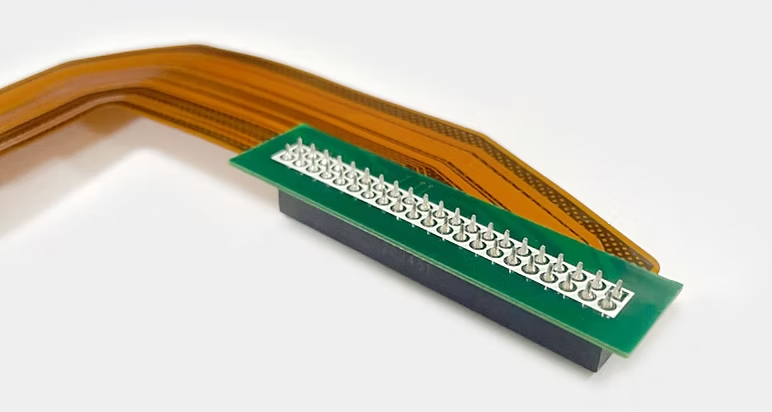

Stiffeners play a crucial role in hybrid flexible designs. These rigid sections—often FR-4 material bonded to specific areas—provide stable mounting zones for connectors and high-pin-count components. At Flex Plus, engineers strategically position stiffeners to balance flexibility in dynamic bend regions with stability in assembly zones. Coverlays protect exposed circuitry while adding minimal thickness, but their application requires careful attention to avoid creating stress concentration points at the coverlay-to-circuit boundary.

Fundamental Differences Between Rigid and Flexible PCB Assembly

SMT assembly on rigid PCBs benefits from inherent dimensional stability throughout the entire process. The board maintains its shape during solder paste printing, component placement, and reflow—allowing standard fixturing and proven thermal profiles. Flexible circuits behave completely differently. Without proper support, they sag under their own weight, shift position during pick-and-place operations, and distort unpredictably when exposed to reflow temperatures.

Thermal expansion presents another critical distinction. Rigid FR-4 boards exhibit relatively predictable expansion coefficients, typically around 14-17 ppm/°C in the XY plane. Polyimide flexible substrates can exceed 20 ppm/°C, and more importantly, they expand non-uniformly due to their thin, anisotropic structure. This differential expansion creates localized stress that can shift components during reflow, even when solder paste has partially melted.

Warpage becomes dramatically more severe with flexible substrates. A 0.1mm thick flexible circuit exposed to 260°C reflow temperatures can bow several millimeters across a 100mm span. This warpage isn’t just a handling problem—it directly affects component placement accuracy and solder joint formation. When the substrate warps during reflow, components can “float” on molten solder until surface tension pulls them toward unintended positions.

Handling requirements differ fundamentally as well. Rigid boards tolerate edge gripping, vacuum hold-down, and direct contact with transport rails. Flexible circuits require distributed support to prevent sagging and specialized edge retention to maintain dimensional reference points. Many standard SMT production lines designed for rigid boards cannot accommodate flexible substrates without significant equipment modifications or custom tooling.

Design for Manufacturability: Pre-Assembly Considerations

Successful SMT assembly for FPCB begins long before components reach the production line. Design for Manufacturability (DFM) analysis must account for the unique constraints of flexible substrates. At Flex Plus, our engineering team conducts comprehensive DFMEA (Design Failure Mode and Effects Analysis) specifically adapted for flexible circuit assembly, identifying potential issues before prototype fabrication begins.

Component placement strategies differ significantly from rigid board layouts. High-mass components should never be positioned in dynamic flex regions, as repeated bending creates fatigue stress at solder joints. Instead, designers should concentrate SMT components in rigid sections or areas reinforced with stiffeners. The transition zone between flexible and rigid regions requires particular attention—solder joints positioned exactly at these boundaries experience maximum mechanical stress during flexing.

Pad design requires adjustment for flexible substrates. Standard IPC guidelines for rigid boards recommend specific pad extensions beyond component terminations, but these recommendations don’t account for substrate movement during reflow. For flexible circuits, engineers should increase pad sizes by 10-15% to provide tolerance for thermal expansion and minor component shifting. This additional copper area also improves solder wetting and creates more robust fillet formation.

Copper weight selection impacts both flexibility and assembly reliability. While 1-ounce copper provides good current carrying capacity, it significantly reduces flexibility and increases stress at bend points. Half-ounce copper balances flexibility with adequate trace width for most applications. For dynamic flex regions requiring thousands of bend cycles, designers should consider rolled annealed copper rather than electrodeposited copper—the former exhibits superior flexibility and fatigue resistance.

Stress concentration points represent a critical DFM consideration often overlooked in initial designs. Sharp corners, abrupt trace width changes, and via locations near component pads all create localized stress points that can lead to failures during assembly or field operation. Rounded corners, gradual trace transitions, and strategic via placement away from high-stress zones all contribute to more robust flexible circuit designs.

Fixturing Solutions: Preventing Movement During Assembly

Specialized fixturing represents the first line of defense against component shifting during SMT assembly for FPCB. Standard vacuum hold-down systems designed for rigid boards prove inadequate for thin flexible substrates. The distributed vacuum pressure required to prevent sagging often exceeds safe levels for polyimide films, potentially causing substrate distortion or damage to circuit traces.

Vacuum tables with custom-profiled surfaces offer a more sophisticated solution. These fixtures incorporate relief areas corresponding to component locations, ensuring the flexible substrate remains flat while providing clearance for component bodies. The vacuum distribution pattern must be carefully designed to apply holding force in non-critical areas while avoiding interference with solder paste deposits or component placement zones.

Custom jigs and carriers transform flexible circuits into quasi-rigid assemblies during processing. At Flex Plus, we design carrier systems that capture the flexible circuit’s edges while providing distributed support across its surface. These carriers travel through the entire SMT line—from solder paste printing through reflow—maintaining dimensional stability throughout all process steps. The carrier design must balance rigidity for positional stability with thermal mass minimization to avoid heat sink effects during reflow.

Temporary stiffeners offer another effective approach for complex flexible circuits requiring multiple assembly operations. These removable rigid supports, typically made from thin FR-4 or aluminum, attach to the flexible substrate using heat-release adhesive or mechanical clips. They provide the dimensional stability needed for precise component placement and survive reflow temperatures without degradation. After assembly completion, gentle heating releases the adhesive, allowing stiffener removal without damaging the flexible circuit.

Magnetic fixture technology has emerged as an innovative solution for certain applications. By incorporating ferromagnetic material into the carrier or fixture base, magnetic fields can apply distributed holding force to the flexible substrate without mechanical contact points. This approach eliminates the risk of physical damage from clamps or vacuum ports while providing easily adjustable holding forces. Flex Plus has pioneered magnetic fixture systems for ultra-thin flexible circuits where traditional clamping methods prove impractical.

Registration pin systems ensure consistent positioning across multiple process steps. Unlike rigid boards, flexible circuits can shift within fixtures due to thermal expansion or handling forces. Precision-machined registration features on both the circuit and fixture provide repeatable alignment accuracy within ±0.05mm—essential for fine-pitch component placement and multi-pass assembly operations.

Solder Paste Printing: Adapting to Flexible Substrates

Solder paste printing on flexible substrates presents unique challenges that demand modified equipment settings and specialized stencil designs. The fundamental issue stems from substrate compliance—when the squeegee blade applies downward pressure during printing, flexible circuits compress and deform, leading to inconsistent paste deposits.

Stencil design for flexible circuits requires thickness adjustments based on pad size and component type. While 0.125mm stencils work well for most rigid board applications, flexible substrates often benefit from thinner stencils (0.1mm or less) to reduce paste volume and minimize component floating during reflow. Conversely, large thermal mass components may require localized stencil thickness increases to ensure adequate solder volume for reliable joint formation.

Aperture design must account for substrate movement during printing. Standard aperture-to-pad ratios (typically 1:1 for rigid boards) may produce excessive paste deposits on flexible circuits due to the squeegee’s downward deflection of the substrate. Reducing aperture width by 5-10% while maintaining pad coverage helps control paste volume and reduces the risk of bridging between fine-pitch pads.

Support beneath the flexible circuit during printing is absolutely critical. Specialized printing tables with adjustable support pins allow technicians to provide localized upward pressure exactly where the squeegee passes, counteracting substrate deflection. This support must be precisely calibrated—too little support allows excessive deflection and poor paste transfer, while excessive support can damage thin flexible circuits or create printing registration errors.

Solder mask considerations differ for flexible circuits as well. The solder mask coating on flexible substrates tends to be thinner and more compliant than on rigid boards, affecting how it defines pad edges. This compliance can lead to solder mask intrusion onto pads, reducing the effective solderable area. Flex Plus addresses this through carefully controlled solder mask application processes that maintain minimum 0.1mm clearance from pad edges while ensuring adequate coverage for electrical isolation.

Paste chemistry selection impacts assembly success on flexible substrates. No-clean solder pastes with lower voiding tendencies and broader reflow windows provide more forgiving process conditions. The paste’s viscosity must be carefully matched to the printing process—too thick and paste transfer suffers, too thin and paste slumps before reflow, causing bridging or component shifting.

Thermal Profiling: Managing Heat in Flexible Circuit Assembly

Thermal profiling for FPCB reflow represents perhaps the most critical process control parameter. Unlike rigid boards with substantial thermal mass that absorbs and distributes heat relatively uniformly, thin flexible circuits respond almost instantaneously to temperature changes. This rapid thermal response creates both opportunities and risks during reflow soldering.

The fundamental challenge stems from thermal mass variation across a typical flexible circuit assembly. Areas with dense component populations or bonded stiffeners act as heat sinks, while bare flexible regions heat and cool rapidly. This thermal imbalance can create temperature differentials exceeding 30°C across a single assembly during reflow, leading to incomplete solder melting in cold zones or component damage in hot zones.

Controlled reflow profiles must be developed specifically for each flexible circuit design. At Flex Plus, we utilize multi-zone convection reflow ovens with at least eight independently controlled heating zones. This granular temperature control allows gradual substrate heating that minimizes thermal shock while achieving solder melting temperatures. The preheat phase becomes particularly critical—flexible substrates require extended preheat (90-120 seconds above 150°C) to ensure uniform temperature distribution before entering the spike zone.

Temperature ramp rates demand careful attention. While rigid boards tolerate 2-3°C/second ramp rates, flexible circuits should not exceed 1.5°C/second to prevent differential expansion between the substrate and components. Excessive ramp rates cause localized stress that can shift components before solder solidifies or create solder joint cracks that manifest as field failures months after assembly.

Peak reflow temperature selection balances complete solder melting with substrate protection. Lead-free SAC305 solder alloys require peaks around 245-250°C, but polyimide substrates can begin degrading above 280°C with extended exposure. The time above liquidus (TAL) becomes the critical control parameter—maintaining 40-70 seconds above 217°C (SAC305 melting point) ensures reliable solder joint formation without excessive thermal exposure.

Moisture removal prior to reflow cannot be overlooked. Flexible circuits, particularly those using adhesive bonding layers, can absorb atmospheric moisture during storage or handling. When this moisture rapidly vaporizes during reflow, it can cause delamination between layers or component “popcorning.” Flex Plus implements mandatory baking procedures (typically 125°C for 4-8 hours depending on substrate thickness) for all flexible circuits before SMT assembly. This pre-bake removes absorbed moisture and stabilizes dimensional characteristics.

Cooling rate control prevents warpage and component shifting during solder solidification. Rapid cooling can lock in thermal stress, causing the assembled flexible circuit to bow or twist after exiting the reflow oven. Controlled cooling at rates not exceeding 2°C/second allows gradual stress relaxation and more uniform solder microstructure formation. Some high-reliability applications benefit from post-reflow stress relief annealing, where assemblies are held at elevated temperatures (150-175°C) for extended periods to relieve residual stress.

Quality Control and Inspection for Flexible Circuit Assemblies

Quality control for SMT assembly on flexible substrates requires inspection techniques adapted to unique flexible circuit geometries. Automated Optical Inspection (AOI) systems designed for flat rigid boards struggle with flexible circuits that may not lie perfectly flat or that incorporate three-dimensional features like formed sections or cable portions.

Specialized AOI programming addresses flexible circuit challenges through adaptive focus algorithms and angled lighting configurations. These systems can accommodate substrate variations of several millimeters while maintaining inspection accuracy for component placement and solder joint formation. At Flex Plus, we program AOI systems with flexible-specific inspection libraries that account for the optical characteristics of polyimide substrates and the unique reflection properties of components mounted on non-rigid surfaces.

X-ray inspection becomes essential for flexible circuits with bottom-terminated components or multi-layer rigid-flex constructions. Traditional 2D X-ray systems provide valuable information about solder joint voiding and hidden defects, but 3D computed tomography (CT) X-ray systems offer superior defect detection for complex assemblies. These advanced systems can resolve internal features within multilayer stacks and detect delamination that would remain hidden with other inspection methods.

Reliability testing specific to flexible circuits includes both electrical validation and mechanical flex testing. Electrical testing follows standard procedures, but mechanical testing requires specialized equipment that simulates real-world flexing conditions. IPC-TM-650 defines test methods for flexible circuits, including dynamic flex testing where assembled circuits undergo thousands of bend cycles while monitoring electrical continuity and solder joint integrity.

Environmental stress testing takes on added importance for flexible circuits deployed in demanding applications. Automotive-qualified flexible circuits must survive thermal cycling from -40°C to +125°C, humidity exposure, and salt spray testing per IATF 16949 requirements. Medical device flexible circuits undergo biocompatibility testing and sterilization cycle validation per ISO 13485 standards. These rigorous qualification programs ensure assemblies perform reliably throughout their intended service life.

Common Defects and Mitigation Strategies

Component shifting during reflow remains the most prevalent defect in flexible circuit SMT assembly. This shifting typically results from inadequate fixturing, excessive thermal mass imbalance, or improper reflow profiles. When components shift, they create either complete opens (no electrical connection) or weakened solder joints prone to field failures. Mitigation requires comprehensive fixturing validation, thermal profiling optimization, and potentially redesigning pad geometries to improve component retention during reflow.

Solder bridging occurs more frequently on flexible circuits than rigid boards due to substrate movement during paste printing and component placement. The flexible substrate’s compliance allows excess paste deposits or component misalignment that manifests as bridging during reflow. Solutions include refined stencil aperture designs, improved printing support, and potentially reducing solder paste volume for fine-pitch areas.

Delamination between layers represents a failure mode unique to flexible circuits, particularly those using adhesive-based constructions. Moisture absorption, excessive reflow temperatures, or mechanical stress during handling can initiate delamination. Prevention requires strict moisture control protocols, validated thermal profiles that avoid excessive peak temperatures, and careful handling procedures throughout assembly.

Component tombstoning—where one end of a chip component lifts off the pad during reflow—results from thermal imbalance between the two component terminations. On flexible circuits, this imbalance intensifies due to uneven heat distribution across the substrate. Addressing tombstoning requires thermal profile adjustments to ensure both component ends reach solder melting temperature simultaneously, along with pad design modifications that balance solderable area on both terminations.

Flex crack propagation from solder joints occurs in dynamic flex regions where designers improperly placed rigid components. The repetitive bending creates fatigue stress that initiates cracks at the solder joint interface, eventually propagating into the flexible substrate. This failure mode demands design corrections—either relocating components to non-flex regions or implementing strain relief features that isolate solder joints from bending stress.

Industry Standards and Continuous Innovation

Adherence to industry standards ensures flexible circuit assemblies meet rigorous quality and reliability requirements across diverse applications. IPC-6013 defines acceptability criteria specifically for flexible and rigid-flex printed boards, covering everything from conductor spacing to via construction. IPC-A-610 provides acceptance criteria for electronic assemblies, with specific sections addressing flexible circuit inspection requirements.

For automotive applications, IATF 16949 certification demonstrates a manufacturer’s commitment to quality management systems specifically adapted to automotive supply chains. This certification requires documented process controls, statistical process capability studies, and comprehensive traceability throughout manufacturing. Medical device flexible circuits demand ISO 13485 certification, ensuring manufacturing processes meet stringent medical device quality management requirements.

At Flex Plus, our commitment to continuous innovation drives ongoing improvements in SMT assembly processes for flexible circuits. Our R&D team investigates emerging technologies like selective soldering for mixed rigid-flex assemblies, laser-based component attachment methods, and advanced thermal management solutions incorporating flexible heat pipes. These innovations expand the boundaries of what’s achievable with flexible circuit assemblies while maintaining the reliability standards our customers demand.

Cross-functional engineering partnerships between Flex Plus and our customers accelerate innovation and problem-solving. When automotive engineers face challenges integrating flexible circuits into electric vehicle battery management systems, our application engineers provide hands-on support—from initial design consultation through pilot production validation. This collaborative approach ensures optimal manufacturability while meeting stringent performance requirements.

Conclusion

SMT assembly for FPCB represents a sophisticated manufacturing discipline requiring specialized knowledge, equipment, and process controls far beyond traditional rigid board assembly. The fundamental challenges—substrate instability, thermal management, and component shifting prevention—demand solutions built on engineering expertise and validated manufacturing processes.

Specialized fixturing systems transform inherently flexible substrates into stable platforms suitable for precision component placement and soldering. Carefully developed thermal profiles balance the competing requirements of complete solder melting, minimal thermal stress, and substrate protection. Together, these techniques enable reliable, high-yield production of flexible circuit assemblies for demanding applications across automotive, medical, and industrial sectors.

For over 20 years, Flex Plus has refined these processes through continuous innovation and close collaboration with customers pushing the boundaries of flexible electronics. Our comprehensive approach—from design for manufacturability consultation through final assembly and testing—ensures flexible circuits not only meet but exceed the reliability standards required for mission-critical applications. As electronics continue evolving toward more compact, flexible form factors, the manufacturing expertise to reliably assemble these advanced circuits becomes increasingly valuable.

The future of flexible electronics depends on manufacturers who understand both the challenges and solutions for SMT assembly on flexible substrates. By combining proven fixturing techniques, optimized thermal profiling, and rigorous quality control, companies can successfully transition from rigid board designs to flexible solutions that unlock new possibilities in product design and functionality.