Walk into any modern facility where smartphones are born, where medical devices take their first breath, or where automotive electronics come to life—you’ll witness a ballet of precision machinery performing what seems like magic. Tiny components, some barely visible to the naked eye, find their exact homes on circuit boards with split-second timing. This is Surface Mount Technology (SMT) assembly, and it’s not just another manufacturing process—it’s the backbone that holds our electronic world together.

Think about the smartphone in your pocket. Inside that sleek device, thousands of components sit on circuit boards no thicker than a credit card. Twenty years ago, achieving this level of miniaturization would have been impossible. Today, it’s standard practice, thanks to SMT assembly. This technology has transformed how we build everything from the sensors in electric vehicles to the life-saving equipment in operating rooms, from the telecommunications infrastructure connecting our world to the wearable devices tracking our health.

For enterprises seeking manufacturing partners capable of scaling from prototypes to mass production, understanding SMT isn’t optional—it’s essential. This process determines whether your product can meet market demands for smaller sizes, better performance, and competitive pricing. At Flex Plus, we’ve spent over two decades perfecting this craft, watching it evolve from a novel approach to an absolute necessity. Let’s explore why modern electronics manufacturing simply cannot survive without SMT assembly.

The SMT Assembly Journey: From Bare Board to Finished Product

Picture an orchestra where every musician must hit their note with microsecond precision. That’s what happens in a professional SMT assembly line. The process begins with bare printed circuit boards entering a carefully choreographed sequence of automated stations, each performing its specialized role with exacting standards.

Solder Paste Application: The Foundation

Everything starts with solder paste—a mixture of tiny metal particles suspended in flux. A precision stencil printer positions a laser-cut metal stencil over the PCB, aligning it to tolerances measured in micrometers. A squeegee blade sweeps across the stencil, depositing precise amounts of solder paste onto designated pads. This isn’t guesswork. Modern systems use vision cameras to verify alignment before every print, ensuring that paste deposits land exactly where they should. For high-volume production, this step repeats thousands of times daily with consistent accuracy that human hands simply cannot match.

The solder paste itself demands respect. It must maintain proper viscosity, remain stable at room temperature, yet flow perfectly during reflow. Expired paste or incorrect storage temperatures can spell disaster for an entire production run. That’s why automated storage systems now monitor paste conditions continuously, alerting operators before quality deviates.

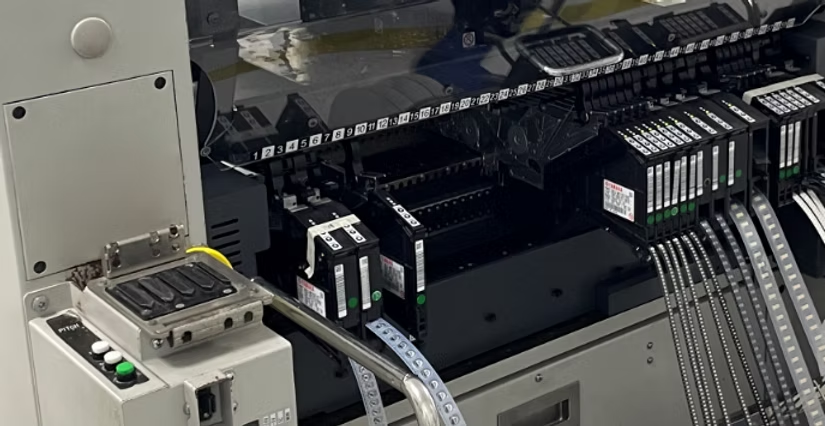

Component Placement: The Dance of Pick-and-Place Machines

Here’s where automation truly shines. High-speed pick-and-place machines equipped with multiple placement heads move with remarkable precision. Using vacuum nozzles, these machines pick components from reels or trays, verify their orientation with vision systems, and place them onto the solder paste deposits—all in fractions of a second. Advanced machines can place 30,000 components per hour with positioning accuracy of ±0.025mm.

For complex rigid-flex PCBs like those we manufacture at Flex Plus, this step becomes even more critical. The machine must account for the board’s flexibility, adjusting placement force to avoid damaging delicate flex circuits while ensuring proper contact with solder paste. Our engineers program these parameters based on years of experience with materials ranging from standard polyimide to specialized TPU substrates.

Reflow Soldering: Where Chemistry Meets Physics

Components positioned, the board enters the reflow oven—a precisely controlled environment where temperature zones guide the assembly through a carefully designed heating profile. First, the flux activates, cleaning the metal surfaces. Then, as temperature rises above the solder’s melting point (typically 217°C for lead-free solder), the metal particles coalesce, forming permanent electrical and mechanical bonds.

This isn’t simple heating. The temperature profile must ramp up gradually to prevent thermal shock, maintain peak temperature long enough for complete wetting without overheating components, then cool at controlled rates to create proper solder grain structure. Modern ovens use multiple heating zones, sometimes twelve or more, each independently controlled to create the ideal thermal journey for your specific board and components.

Inspection and Testing: The Quality Gateway

After reflow, every board faces scrutiny. Automated Optical Inspection (AOI) systems capture high-resolution images of each solder joint, comparing them against golden standards to detect defects like insufficient solder, bridging, or component misalignment. X-ray inspection penetrates the board, revealing hidden issues under components with leads beneath their bodies—particularly critical for Ball Grid Arrays (BGAs) and other advanced packages.

But visual inspection tells only part of the story. Electrical testing verifies that circuits function as designed. Flying probe testers or bed-of-nails fixtures check continuity, resistance, and capacitance, ensuring that the physical assembly translates into electrical performance. For medical devices requiring ISO 13485 certification or automotive electronics demanding IATF 16949 compliance—standards we maintain at Flex Plus—this testing isn’t merely thorough; it’s exhaustive.

The Advantages That Changed Everything

Why has SMT assembly become indispensable? The answer lies in advantages so compelling that reverting to older methods would be like abandoning smartphones for rotary phones.

Miniaturization: The Space Revolution

Consider a 0402 resistor—measuring just 0.4mm × 0.2mm, smaller than a grain of salt. Through-hole components performing the same function might be ten times larger. This size reduction cascades through entire designs. Boards shrink. Devices become lighter. Space once occupied by a single through-hole component can now house ten or twenty surface mount parts.

This matters profoundly in industries we serve. In wearable medical devices using our ultra-thin flexible PCBs—some just 25 microns thick—every fraction of a millimeter counts. For electric vehicle manufacturers integrating electronics into tight spaces, component miniaturization isn’t a luxury; it’s a requirement. The drone industry, developing devices for low-altitude airspace applications, depends on lightweight electronics that maintain full functionality while minimizing weight.

Component Density: More Power, Less Space

SMT enables double-sided assembly, placing components on both faces of a PCB. Combined with smaller component footprints, this dramatically increases circuit density. A board that once held 100 through-hole components might accommodate 500 or more SMT parts. This density translates directly into functionality—more features, better performance, enhanced capabilities, all within the same physical footprint.

For our clients developing optical transceivers or telecommunications equipment, this density advantage enables sophisticated signal processing and data handling within industry-standard form factors. You’re not just fitting more components; you’re enabling new capabilities that weren’t previously possible.

Performance Enhancement: The Electrical Advantage

Shorter lead lengths mean reduced parasitic inductance and capacitance—physics that matters intensely at high frequencies. SMT components typically have lead lengths measured in fractions of a millimeter, compared to several millimeters for through-hole parts. This enables cleaner signals, faster switching speeds, and better high-frequency performance.

At Flex Plus, we’ve seen this advantage prove critical in smart helmet applications for F1 racing, where milliseconds matter, and in augmented reality wearables processing massive data streams. The reduced lead length also minimizes electromagnetic interference, crucial for medical devices operating in sensitive environments or automotive electronics meeting stringent EMC requirements.

Production Efficiency: The Economic Imperative

Automation drives cost down while driving quality up—a rare combination. Once programmed and verified, SMT lines run with minimal operator intervention, producing thousands of boards with consistent quality. This efficiency matters enormously for high-volume production. Whether you’re manufacturing consumer electronics by the millions or industrial control systems by the thousands, the per-unit cost advantage of SMT becomes undeniable.

The efficiency extends beyond assembly speed. SMT components typically cost less than through-hole equivalents. Reduced board size means more circuits per panel, lowering material costs. Faster production means shorter lead times, improving inventory management and cash flow. These advantages align perfectly with our philosophy at Flex Plus—delivering certified excellence while maintaining competitive economics for volume production.

Navigating the Challenges: Mastery Through Experience

No technology exists without challenges. SMT assembly demands expertise, precision equipment, and unwavering attention to detail. Understanding these challenges—and how to overcome them—separates competent manufacturers from exceptional partners.

Design Complexity: The Engineering Challenge

As components shrink and density increases, design becomes exponentially more complex. Thermal management grows critical—densely packed components generate heat that must dissipate effectively. Our breakthrough technology in flexible heat dissipation flow channels addresses this directly, reducing operating temperatures in high-power applications like automotive LED systems.

Component placement isn’t arbitrary. Engineers must consider thermal gradients during reflow, ensuring large thermal mass components don’t create temperature differentials that cause smaller parts to tombstone (stand on end) or shift position. Pad design requires careful optimization—too large, and solder wicks excessively; too small, and joints lack strength. These decisions demand deep understanding of both design principles and manufacturing realities.

At Flex Plus, our Design for Manufacturing (DFM) support bridges this gap. Our engineers review designs before production, identifying potential issues and recommending optimizations. This collaboration reduces prototype iterations, accelerates time-to-market, and ensures manufacturability at scale.

Thermal Management: The Heat Puzzle

Modern electronics pack tremendous power into tiny spaces. Smartphones process data comparable to supercomputers from two decades ago. Electric vehicle controllers switch hundreds of amperes. Medical imaging devices run sophisticated processors continuously. All this activity generates heat that flexible PCBs must manage effectively.

Thermal vias, copper planes, and strategic component placement help, but flexible circuits present unique challenges. Unlike rigid boards with thick copper layers and heat sinks, flex circuits prioritize thinness and flexibility. This demands innovative approaches. Our pioneering thermal pathway technology embeds heat dissipation channels within flexible structures, conducting heat away from critical components without sacrificing flexibility or adding thickness.

For clients developing high-power applications, we provide material consultation, helping select substrates and copper weights that balance electrical performance, thermal management, flexibility, and reliability. This expertise, accumulated over 20+ years, proves invaluable when pushing performance boundaries.

Defect Prevention: The Quality Imperative

SMT’s precision cuts both ways. While enabling incredible functionality, the process creates opportunities for defects that through-hole assembly rarely encounters. Tombstoning occurs when uneven heating causes components to stand vertically. Bridging happens when excess solder connects adjacent pads. Insufficient solder creates weak joints prone to failure.

Preventing these defects requires holistic thinking. Solder paste quality must be monitored continuously. Stencil thickness and aperture design need optimization for each component type. Reflow profiles demand customization based on board mass, component mix, and solder formulation. Even humidity affects outcomes—moisture absorbed by components can vaporize during reflow, creating voids or popcorning effects.

Our systematic approach combines advanced equipment with process discipline. Automated storage systems maintain paste at optimal temperature and humidity. Vision systems verify every placement. Multiple temperature sensors throughout reflow ovens ensure profile accuracy. Statistical Process Control (SPC) tracks trends, identifying drift before it becomes defects. This vigilance, backed by ISO 9001, ISO 13485, and IATF 16949 certifications, ensures consistent quality whether producing ten prototypes or ten thousand production units.

Equipment Investment: The Capital Reality

Professional SMT assembly requires significant capital investment. A complete line—including solder paste printer, pick-and-place machines, reflow oven, and inspection systems—can cost millions of dollars. This reality creates barriers for companies attempting in-house assembly and emphasizes the value of partnering with established manufacturers.

At Flex Plus, our 16,000+ square meter facility houses state-of-the-art SMT equipment alongside our flexible PCB fabrication capabilities. This integration enables comprehensive services from bare board manufacturing through complete assembly—eliminating hand-offs between vendors, reducing lead times, and improving quality through unified responsibility.

The FlexPlus Commitment: Partnership in Excellence

Modern electronics manufacturing demands more than capability—it requires partnership. Companies developing innovative products need manufacturers who understand not just processes, but applications. Who can translate product requirements into manufacturing specifications. Who bring solutions, not just capacity.

Over two decades, we’ve built this expertise across diverse sectors. Our rigid-flex PCBs reduce interconnection points by 87%, dramatically improving reliability in aerospace systems and medical devices. Our ultra-thin flexible circuits, down to 25 microns, enable next-generation wearables and implantable medical devices. Our TPU circuit technology opens possibilities in beauty tech and medical equipment that traditional materials couldn’t address.

But technology alone isn’t enough. Our certified processes—ISO 9001 for quality management, ISO 13485 for medical devices, IATF 16949 for automotive, ISO 14001 for environmental responsibility—provide assurance that every board meets stringent international standards. Our comprehensive engineering support, from material consultation through DFM analysis to technical feedback during production, makes us partners in your success, not just vendors fulfilling orders.

Looking Forward: The Indispensable Foundation

As electronics continue evolving—devices growing smaller, more powerful, more integrated into daily life—SMT assembly becomes even more critical. Electric vehicles demand increasingly sophisticated electronics. Medical devices push toward minimally invasive implantables. Consumer electronics race toward foldable, wearable, even invisible form factors. Every advancement depends on our ability to place smaller components more precisely onto increasingly complex flexible and rigid-flex circuits.

This isn’t merely manufacturing; it’s enabling innovation. When designers envision breakthrough products, SMT assembly determines whether those visions can become reality. When engineers specify performance parameters, SMT capability defines what’s achievable. When enterprises commit to bringing products to market, SMT reliability determines whether they’ll succeed or struggle.

At Flex Plus, we view this responsibility seriously. Our investment in advanced equipment, our commitment to certified processes, our cultivation of engineering expertise—all serve one goal: being the trusted partner that transforms your innovative concepts into reliable products meeting the highest international standards.

Modern electronics can’t survive without SMT assembly because this technology embodies the precision, efficiency, and capability that today’s products demand. More accurately, modern electronics can’t survive without manufacturing partners who’ve mastered SMT assembly through years of dedicated practice, continuous improvement, and unwavering commitment to excellence.

Whether you’re developing autonomous vehicle systems, life-saving medical devices, next-generation telecommunications equipment, or cutting-edge consumer electronics, your success depends on manufacturing partners who bring not just capabilities, but proven expertise. Partners who understand that behind every specification lies a challenge requiring deep knowledge to overcome. Partners who view quality not as an expense but as a foundation.

That’s the partnership Flex Plus offers—built on 20+ years of specialized experience, backed by comprehensive certifications, empowered by advanced technology, and driven by commitment to your success. Because in a world where electronics enable everything, manufacturing excellence isn’t optional—it’s indispensable.