Every time you unlock your smartphone, check your smartwatch, or rely on your car’s advanced safety features, you’re using technology powered by an engineering marvel most people have never heard of: rigid flexible PCBs. These hybrid circuit boards combine the structural stability of traditional rigid boards with the dynamic performance of flexible circuits, creating a solution that’s transforming how our devices work.

Think about the last time you folded your laptop screen closed or adjusted your wireless earbuds. Inside those devices, rigid flexible PCBs are quietly doing their job—bending, flexing, and maintaining perfect electrical connections through thousands of cycles. This hidden technology represents one of the most significant advances in modern electronics, enabling innovations that simply weren’t possible a decade ago.

At Flex Plus (Xiamen) Co., Ltd, we’ve spent over 20 years perfecting this technology, watching it evolve from a specialized solution for aerospace applications to an essential component in everyday consumer electronics. The journey has taught us that the best technology often goes unnoticed—it just works, reliably and efficiently, day after day.

The Engineering Magic Behind Rigid Flexible PCBs

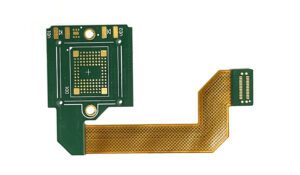

Rigid flexible PCBs are exactly what their name suggests: a single circuit board that combines rigid sections with flexible sections. But understanding their structure reveals why they’re so revolutionary. The rigid sections, typically made from traditional IPC-compliant FR4 material, provide structural support and house electronic components. These areas offer the same stability and durability you’d expect from any standard circuit board. Meanwhile, the flexible sections—usually constructed from polyimide material—allow the board to bend, fold, and twist without losing electrical connectivity.

What makes this combination so powerful is how it eliminates traditional connection points. In older electronics, designers would use separate rigid boards connected by cables, wires, or connectors. Each connection point represents a potential failure point—a place where vibrations, thermal cycling, or simple wear and tear could cause problems. By integrating everything into a single rigid flexible PCB, manufacturers can eliminate up to 60% of these potential failure points, dramatically improving device reliability—a critical advantage that our flexible circuit board design guidelines emphasize for optimal manufacturability.

The durability advantages are remarkable. Standard rigid PCBs can crack under repeated stress or in high-vibration environments. Pure flexible circuits, while bendable, lack the structural support needed for mounting heavier components or providing chassis stability. Rigid flexible PCBs solve both problems simultaneously. The rigid sections anchor components securely, while the flexible sections absorb vibrations and accommodate movement without fracturing.

Temperature cycling—the repeated heating and cooling that electronics experience during normal operation—poses another challenge that rigid flexible PCBs handle exceptionally well. Traditional multi-board systems with connectors suffer because different materials expand and contract at different rates, creating stress at connection points. A unified rigid flexible PCB distributes these thermal stresses more evenly, maintaining integrity across temperature ranges from -40°C to +125°C or even higher in specialized applications.

Space optimization represents perhaps the most visible benefit. By allowing circuits to fold into three-dimensional configurations, rigid flexible PCBs can reduce device volume by 50% or more compared to traditional designs. This isn’t just about making devices smaller—it’s about making entirely new form factors possible. Without rigid flexible PCB technology, we wouldn’t have ultra-thin smartphones, compact medical implants that meet ISO 13485 medical device quality standards, or the sophisticated sensor arrays that make modern electric vehicles possible.

Powering Innovation Across Industries

The applications for rigid flexible PCBs extend far beyond consumer electronics, though that’s where most people encounter them daily. In the electric vehicle industry, these boards are enabling the revolution in automotive electronics. Modern EVs contain dozens of sophisticated sensors and control systems, from Head-Up Displays that project critical information onto windshields to Advanced Driver Assistance Systems (ADAS) that use cameras, radar, and Lidar to prevent accidents.

Consider the side-mounted camera systems replacing traditional mirrors in cutting-edge vehicles. These Camera Monitor Systems (CMS) must withstand constant vibration, extreme temperature variations, and thousands of adjustment cycles—all while maintaining perfect image quality and electrical connectivity. Rigid flexible PCBs provide the ideal solution, with rigid sections mounting the camera components and flexible sections routing signals through moving hinges and pivot points. This same technology powers parking sensors, wing mirror assemblies, and entry cameras throughout the vehicle.

Medical device manufacturers face even more demanding requirements. Devices intended for implantation or frequent patient contact must meet ISO 13485 certification standards while operating flawlessly in biological environments. Our expertise in medical-grade Pyralux applications ensures biocompatibility considerations are integrated from the earliest design stages. Rigid flexible PCBs enable the creation of biomedical-compatible devices that are both compact enough for minimally invasive procedures and durable enough for long-term reliability. From cardiac monitors to diagnostic imaging equipment, these circuits are making healthcare more effective and less invasive.

The aerospace and defense sectors pioneered rigid flexible PCB technology out of necessity. When every gram matters and failure isn’t an option, the reliability and weight savings of rigid flexible designs become critical advantages. Modern drones, Electric Vertical Takeoff and Landing (eVTOL) vehicles, and air taxis depend on these lightweight, reliable circuit boards to function safely. A single rigid flexible PCB can replace multiple traditional boards and their associated wiring harnesses, reducing weight by several kilograms while simultaneously improving reliability.

In telecommunications, the push toward smaller, faster equipment has made rigid flexible PCBs essential. Optical transceiver modules that handle high-speed data transmission require extremely compact designs with minimal signal loss. The three-dimensional routing capabilities of rigid flexible PCBs allow engineers to position components optimally for signal integrity while fitting everything into spaces that would be impossible with traditional rigid boards.

Smart helmet technology for F1 racing and mining applications showcases another innovative use case. These intelligent headgear systems must integrate sensors, displays, and communication equipment into a curved, impact-resistant housing that’s comfortable enough for extended wear. Rigid flexible PCBs conform to the helmet’s shape while providing the structural support needed for secure component mounting—a combination that traditional circuit board technology simply cannot achieve.

Navigating the Design Challenges

Despite their advantages, designing rigid flexible PCBs requires careful engineering and deep technical expertise. Understanding critical flexible PCB design rules prevents costly production failures before they occur. The transition zones between rigid and flexible sections present unique challenges that designers must address from the earliest conceptual stages. Material selection becomes critical—engineers must choose substrates, adhesives, and copper foils that work harmoniously while meeting mechanical, electrical, and environmental requirements.

The bend radius—how tightly a flexible section can curve without damaging traces or causing electrical failures—demands particular attention. While flexible circuits can bend, they cannot bend infinitely. Engineers must calculate minimum bend radii based on copper thickness, number of layers, and expected cycle life. A radius too small risks cracking copper traces or delaminating layers. A radius too large wastes valuable space and defeats the purpose of using flexible technology. At Flex Plus, we’ve developed sophisticated modeling tools that predict mechanical stress under various bending scenarios, helping designers optimize their layouts before manufacturing begins.

Layer stacking presents another complex challenge. In a standard rigid PCB, all layers maintain consistent properties throughout the board. In rigid flexible designs, layer counts may vary between rigid and flexible sections. A board might have eight layers in rigid areas housing dense component populations but only two layers in flexible sections to maintain bendability. Transitioning smoothly between these different stack-ups while maintaining electrical continuity and impedance control requires expertise that comes only from years of experience.

Trace routing in flex sections follows different rules than in rigid sections. Traces must follow the neutral axis of the flexible material to minimize stress during bending. They should run perpendicular to the bend direction when possible, with curved rather than angular routing to distribute mechanical stress. Rigid PCB design tools often suggest routing patterns that would fail immediately in flexible sections, making specialized knowledge essential.

The manufacturing process itself presents unique challenges. While rigid PCBs follow well-established fabrication procedures, rigid flexible boards require specialized equipment and processing steps. The combination of materials must laminate under precisely controlled temperature and pressure profiles. For engineers seeking to master these complexities, our comprehensive guide on flexible PCB design from concept to manufacturing-ready files provides invaluable insights into the entire process. Drilling must accommodate both rigid and flexible sections without delamination. The cover layers protecting flexible sections require careful alignment and bonding. Each step demands process control that exceeds typical rigid PCB manufacturing requirements.

Despite these challenges, the engineering investment pays substantial dividends. A well-designed rigid flexible PCB delivers reliability improvements that translate directly to reduced warranty claims and enhanced brand reputation. The space savings enable product differentiation in competitive markets. The reduction in assembly complexity lowers manufacturing costs despite higher board costs, particularly in medium to high volume production.

Looking Toward the Future

The future of rigid flexible PCB technology points toward even greater integration and sophistication. As consumer devices continue shrinking while gaining functionality, the demand for three-dimensional circuit solutions will only intensify. Emerging applications in augmented reality, AI-powered wearables, and beauty tech gadgets are pushing the boundaries of what’s possible with conventional electronics packaging.

Augmented reality glasses and AI wearables present particularly demanding design challenges. As AR technology continues evolving toward mass adoption, the demand for sophisticated circuit solutions that can handle complex sensor integration grows exponentially. These devices must fit comfortably on the human body while incorporating sensors, displays, processors, and batteries. The curved surfaces and tight spaces make rigid flexible PCBs not just advantageous but essential. Future generations of these devices will likely incorporate even more sophisticated rigid flexible designs, with multiple fold zones and increasingly complex three-dimensional routing.

The beauty tech industry—an emerging sector creating tech-driven beauty gadgets—is discovering the advantages of rigid flexible PCBs for creating ergonomic devices that conform to body contours. These applications require biocompatible materials and ultra-reliable performance, specifications that align perfectly with advanced rigid flexible PCB capabilities.

Material science advances are enabling new possibilities. Transparent PCB technology, stretchable circuits using TPU substrates, and ultra-thin designs achieving overall thicknesses below 100 microns are moving from research labs into commercial production. These innovations will enable product categories that don’t exist yet, just as rigid flexible PCBs enabled today’s smartphone designs a decade ago.

Manufacturing technology continues advancing as well. At Flex Plus, we’ve invested in breakthrough capabilities like flexible substrate COB (Chip-on-Board) technology, which bonds semiconductor dies directly onto flexible circuits. This integration achieves component densities and thinness levels impossible with traditional packaging approaches. Our die bonding precision, with wafer offset angle tolerance controlled within ±5°, exceeds industry standards and opens new possibilities for miniaturization.

Environmental considerations are driving innovation too. The electronics industry faces growing pressure to reduce waste and energy consumption. Rigid flexible PCBs contribute to sustainability by eliminating connectors, reducing assembly steps, and enabling more compact devices that require less raw material. As ISO 14001 environmental certification becomes more prevalent, manufacturers who’ve mastered efficient rigid flexible PCB production will hold competitive advantages.

The integration of advanced testing and quality control continues improving. Modern rigid flexible PCB manufacturers employ automated optical inspection (AOI), electrical testing, and mechanical stress testing to verify every board meets specification. These quality systems ensure that the reliability advantages of rigid flexible designs translate to real-world performance.

Engineering the Invisible Revolution

Rigid flexible PCBs represent a technology revolution hiding in plain sight. Every day, billions of people depend on devices powered by these sophisticated circuit boards without ever realizing the engineering complexity enabling their seamless operation. From the smartphone in your pocket to the medical devices saving lives, from the electric vehicles transforming transportation to the aerospace systems expanding human capabilities—rigid flexible PCBs are there, working reliably and efficiently.

At Flex Plus, we’ve witnessed this technology mature from specialized applications requiring custom engineering to standardized solutions accessible across industries. Our ISO 9001, ISO 13485, and IATF 16949 certifications ensure that every board we manufacture meets the highest international quality standards. When evaluating partners, understanding critical supplier selection factors helps ensure you’re working with a genuine manufacturer rather than trading company middlemen., whether it’s destined for a consumer device or a mission-critical aerospace application.

The hidden nature of this technology reflects its success. When rigid flexible PCBs do their job properly, users never think about them. Devices simply work, through thousands of flex cycles, extreme temperatures, and demanding environments. This reliability stems from thoughtful engineering, precise manufacturing, and continuous innovation—values that have guided our work for over two decades.

As electronics continue evolving toward smaller, more capable, and more reliable devices, rigid flexible PCB technology will become even more essential. The challenges of tomorrow’s innovations—whether in low-altitude aviation, advanced medical treatments, or technologies we haven’t imagined yet—will require the unique capabilities that only rigid flexible PCBs can provide. And engineers will continue pushing the boundaries, creating solutions that seem impossible until they become commonplace.

The next time you use a smart device, take a moment to appreciate the invisible engineering marvel making it possible. Somewhere inside, a rigid flexible PCB is bending, flexing, and faithfully conducting electrons exactly where they need to go—a small miracle of modern engineering that’s changing the world one device at a time.