In today’s fast-paced electronics market, the quality of your products often hinges on decisions made early in the supply chain. When it comes to flexible printed circuit boards (FPCBs), selecting the right flexible PCB supplier isn’t just about finding the lowest quote or the quickest delivery time. Yet many engineering and procurement teams continue to evaluate suppliers primarily on these two metrics, overlooking critical factors that can significantly impact product performance, reliability, and long-term success.

With flexible PCBs becoming increasingly crucial components in everything from medical devices to electric vehicles, the stakes of supplier selection have never been higher. Let’s explore seven often-overlooked factors that should be guiding your flexible PCB supplier decisions.

1. Beyond Basic Certifications: Quality as a Strategic Advantage

While ISO 9001 certification has become a standard expectation, truly exceptional flexible PCB suppliers differentiate themselves through industry-specific certifications that align with your product requirements. For medical device manufacturers, a supplier with ISO 13485 certification demonstrates a specialized commitment to quality systems for medical applications. Similarly, automotive electronics developers should prioritize suppliers with IATF 16949 certification, ensuring compliance with the stringent requirements of the automotive industry.

Quality isn’t just about meeting specifications—it’s about consistency and reliability. Leading flexible PCB suppliers adhere to IPC-6013 standards specifically developed for flexible circuits, ensuring that your components meet internationally recognized benchmarks for performance and reliability. These suppliers maintain comprehensive documentation of their testing procedures and results, giving you confidence in their quality control processes.

Customer reviews and case studies provide valuable insights into a supplier’s real-world performance. Look for suppliers who transparently share their success stories and aren’t afraid to discuss how they’ve overcome challenges. Their experience in solving complex technical problems in your industry can prove invaluable to your own projects.

2. Technical Capabilities That Match Your Project Requirements

The technical requirements of flexible PCB applications vary dramatically across industries. A supplier that excels at producing simple single-layer circuits for consumer electronics might struggle with the complex multilayer designs needed for aerospace applications or the ultra-thin requirements of medical implantable devices.

When evaluating a flexible PCB supplier, look beyond general capabilities to assess their specific expertise in your application area. Have they successfully manufactured circuits with similar layer counts, line width/spacing requirements, and material specifications? Can they handle the unique challenges of your industry, such as the high-reliability demands of industrial control systems or the miniaturization requirements of telecommunications equipment?

Advanced manufacturing capabilities such as impedance control, blind and buried vias, and controlled dielectrics are increasingly important for high-performance applications. Suppliers with experience in rigid-flex construction offer particular value for applications requiring both flexibility and structural support, such as those found in augmented reality devices or smart helmets.

3. Material Selection Expertise and Supply Chain Stability

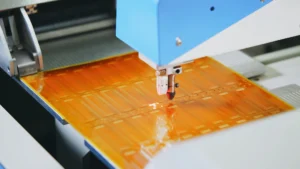

The performance of a flexible PCB is inherently tied to its material composition. Polyimide remains the gold standard substrate for high-end flexible circuits due to its excellent thermal stability, mechanical strength, and chemical resistance. However, alternative materials like liquid crystal polymer (LCP) offer advantages for high-frequency applications, while TPU (thermoplastic polyurethane) provides options for biocompatible or stretchable circuits needed in medical or wearable applications.

A knowledgeable flexible PCB supplier should guide material selection based on your specific application requirements, helping you navigate tradeoffs between cost, performance, and manufacturability. They should understand how material choices affect key parameters like flexibility, dimensional stability, and thermal performance across the operating conditions of your product.

In today’s volatile supply chain environment, suppliers with established relationships with multiple material vendors provide an additional layer of security. Ask potential suppliers about their material procurement strategies and how they mitigate supply chain risks to ensure consistent availability of your required materials.

4. Understanding the True Cost Drivers

The unit price of flexible PCBs is influenced by numerous factors beyond simple board dimensions. Sophisticated buyers understand these cost drivers and work with suppliers to optimize designs for cost-effectiveness without compromising performance.

Key cost elements include:

– Material selection: Premium materials like polyimide with adhesiveless construction cost more but offer superior performance and reliability.

– Layer count: Each additional layer significantly increases manufacturing complexity and cost.

– Circuit density: Finer line widths and spacings require more sophisticated equipment and tighter process controls.

– Panel utilization: Optimizing design layout to maximize the number of circuits per manufacturing panel can reduce unit costs by 15-20%.

– Volume commitments: Higher volumes enable suppliers to amortize setup costs and optimize manufacturing processes.

A transparent flexible PCB supplier will help you understand these cost drivers and suggest design modifications that can improve manufacturability and reduce costs. They’ll provide detailed quotations that break down costs by category, helping you make informed decisions about design tradeoffs.

5. Manufacturing Capabilities and Technology Investment

The flexible PCB industry continues to evolve rapidly, with advancements in materials, manufacturing processes, and testing methods. Suppliers that consistently invest in new equipment and technologies demonstrate a commitment to staying at the forefront of the industry.

When evaluating manufacturing capabilities, consider factors such as:

– Minimum feature size: Can they reliably produce the line widths and spacings required for your application?

– Maximum circuit size: For applications requiring long flex circuits (up to 3 meters in some cases), specialized equipment is necessary.

– Via technology: What are their capabilities for laser drilling, controlled depth drilling, and via filling?

– Surface finishes: Do they offer the appropriate options for your assembly and reliability requirements?

Advanced testing facilities are equally important. Leading suppliers utilize automated optical inspection (AOI), flying probe testing, impedance testing, and reliability testing (such as flex testing to simulate actual use conditions) to ensure product quality. These capabilities become particularly crucial for applications in industrial control systems and augmented reality devices where performance demands are exceptionally high.

6. Communication and Design Support

The complexity of flexible PCB design makes effective communication and technical support critical success factors. The best supplier relationships involve collaborative partnerships rather than simple transactional interactions.

Evaluate potential flexible PCB suppliers on their ability to:

– Provide comprehensive design for manufacturability (DFM) feedback

– Offer material selection guidance based on application requirements

– Communicate clearly about manufacturing constraints and design rules

– Respond promptly to technical inquiries and production updates

– Support design iterations with quick prototyping capabilities

For OEM partners and R&D engineers, this level of communication becomes even more critical during the development phase. A supplier that can identify potential issues before production and suggest appropriate modifications can save significant time and money by avoiding redesigns and production delays.

Look for suppliers that assign dedicated technical support personnel to your account and maintain clear documentation of design requirements and manufacturing specifications. Their ability to provide detailed production status updates and quality reports demonstrates a commitment to transparency that builds trust and facilitates problem resolution.

7. Long-term Partnership Potential

Perhaps the most overlooked factor in flexible PCB supplier selection is the potential for a long-term strategic partnership. As your products evolve and your production volumes change, your supplier’s ability to scale and adapt becomes increasingly important.

Consider whether a potential supplier:

– Has sufficient capacity to accommodate your growth projections

– Demonstrates financial stability and a clear business continuity plan

– Invests in research and development of new technologies

– Shows flexibility in addressing changing requirements

– Maintains consistent quality across varying production volumes

Industries like low-altitude airspace innovation (drones, eVTOL vehicles) and beauty tech are experiencing rapid evolution of product requirements. A flexible PCB supplier that can grow with these changing needs becomes an invaluable partner rather than just a component vendor.

Conclusion: A Holistic Approach to Supplier Selection

Selecting the right flexible PCB supplier requires a comprehensive evaluation that goes far beyond price and delivery metrics. By considering the seven factors outlined above, you can identify partners who will contribute to your product’s success through quality, innovation, and reliability.

The most successful electronics manufacturers recognize that their flexible PCB supplier relationships are strategic assets that directly impact their ability to innovate and compete. They evaluate suppliers holistically, considering both immediate project requirements and long-term partnership potential.

As flexible PCBs continue to enable advancements in industries ranging from medical devices to aerospace, the importance of working with certified, experienced suppliers only increases. The right flexible PCB supplier doesn’t just deliver components—they deliver expertise, innovation, and reliability that become integral parts of your product’s success story.

By prioritizing quality, technical capabilities, material expertise, cost transparency, manufacturing capabilities, communication, and partnership potential, you’ll build supplier relationships that create lasting competitive advantages in an increasingly demanding marketplace.