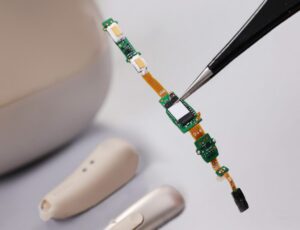

In today’s rapidly evolving technological landscape, the invisible components that power our devices are becoming increasingly sophisticated. Among these hidden heroes, flexible printed circuit boards (PCBs) have emerged as the unsung champions of modern electronics. These bendable brains represent a remarkable engineering achievement that enables the sleek, compact devices we now take for granted. Custom flexible PCB manufacturing has revolutionized how we design and build everything from smartphones to medical implants, creating new possibilities that were once thought impossible.

Unlike their rigid counterparts, flexible PCBs can bend, fold, and twist while maintaining electrical integrity. This fundamental characteristic has made them indispensable in industries where space constraints, weight considerations, and unique form factors are critical design factors. From the compact interiors of your smartphone to life-saving medical devices and the advanced systems in electric vehicles, flexible PCBs are the silent enablers of technological innovation.

The Revolutionary Advantages of Custom Flexible PCBs

The rise of custom flexible PCB manufacturing has introduced a range of benefits that traditional rigid boards simply cannot match. One of the most significant advantages is space optimization. In an era where devices continuously shrink while adding more functionality, flexible PCBs allow designers to utilize three-dimensional spaces efficiently. They can be folded, rolled, or curved to fit into oddly-shaped enclosures, enabling the creation of smaller, more ergonomic products.

Weight reduction represents another crucial advantage. Flexible PCBs are inherently lightweight, weighing up to 75% less than their rigid equivalents. This characteristic makes them ideal for applications where every gram matters, such as drones, electric vertical takeoff and landing (eVTOL) vehicles, and portable medical devices. The aviation industry, in particular, has embraced custom flexible PCB manufacturing to reduce aircraft weight and improve fuel efficiency.

Durability stands as perhaps the most surprising benefit of flexible circuits. While the term “flexible” might suggest fragility, these PCBs actually offer enhanced reliability through their ability to absorb vibrations and withstand repeated flexing. A well-designed flexible PCB can endure thousands of bend cycles without failing, making them perfect for applications involving movement or environments with significant vibration. This intrinsic durability translates to longer product lifespans and reduced maintenance needs.

Beyond these primary advantages, flexible PCBs also deliver improved thermal management, better electrical performance at high frequencies, and resistance to harsh chemicals and environments. Custom flexible PCB manufacturing allows engineers to optimize these characteristics for specific applications, creating tailored solutions that precisely meet the needs of each unique project.

The Specialized Materials and Manufacturing Expertise

Creating high-quality flexible PCBs requires specialized materials and manufacturing processes that differ significantly from those used for rigid boards. The foundation of most flexible circuits is polyimide, a remarkable material that maintains its mechanical and electrical properties across extreme temperature ranges while offering excellent flexibility. Polyimide substrates as thin as 25 microns can be used in ultra-thin designs, pushing the boundaries of what’s physically possible in electronic circuits.

The manufacturing process begins with precise design, where engineers must consider not only the electrical requirements but also the mechanical stresses the circuit will endure during use. Unlike rigid PCBs, flexible circuits must be designed with bend radii, neutral bend axes, and strain relief features to ensure reliable operation throughout their service life.

The fabrication process involves multiple precision steps, including copper etching, lamination, drilling, and plating. Advanced techniques such as laser drilling enable the creation of micro-vias as small as 50 microns, facilitating high-density interconnects in minimal space. Surface treatments and specialized coverlay materials provide protection against environmental factors while maintaining flexibility.

Testing presents unique challenges for custom flexible PCB manufacturing. Traditional test fixtures designed for rigid boards often cannot accommodate the three-dimensional nature of flexible circuits. Specialized test methods and equipment are required to verify both electrical functionality and mechanical durability. Manufacturers like Flex Plus (Xiamen) Co., Ltd. employ rigorous testing protocols including automated optical inspection, flying probe testing, and dynamic bend testing to ensure each circuit meets strict quality standards.

The entire manufacturing process must adhere to international standards such as IPC-6013 (the flexible circuit standard in the United States), IPC/JPCA (Japan’s flexible circuit standard), and TPCA (Taiwan’s flexible circuit standard). Compliance with these standards ensures consistent quality and reliability across diverse applications and industries.

Applications Across Industries: Enabling Innovation Everywhere

The versatility of custom flexible PCB manufacturing has led to its adoption across an impressive range of industries, each leveraging the unique properties of flexible circuits to overcome specific challenges.

In the automotive industry, particularly electric vehicles, flexible PCBs have become essential components in numerous systems. They enable the compact, lightweight design of head-up displays, side-view camera modules, parking sensors, Lidar systems, and battery management systems. Their ability to withstand vibration, temperature fluctuations, and repeated movement makes them ideal for the demanding automotive environment.

Medical device manufacturers have embraced flexible PCBs for their biocompatibility and ability to conform to the human body. Implantable devices such as pacemakers and cochlear implants rely on ultra-thin, flexible circuits that can safely operate within the body for years. Wearable health monitors utilize flexible PCBs to create comfortable, unobtrusive devices that can continuously track vital signs. The biomedical compatibility of modern flexible circuit materials, coupled with ISO 13485 certification, ensures these applications meet strict safety requirements.

The telecommunications industry depends heavily on flexible circuits to create compact, reliable equipment. Optical transceivers, which convert electrical signals to optical signals and vice versa, utilize flexible PCBs to pack complex circuitry into incredibly small form factors. The high-frequency performance of flexible circuits makes them ideal for these applications, where signal integrity is paramount.

In the emerging field of augmented reality (AR) and wearable technology, flexible PCBs enable the creation of lightweight, comfortable devices. Smart glasses, AR headsets, and other wearables benefit from the ability to conform circuits to curved surfaces while maintaining reliable electrical connections. The low weight and adaptable form factor of flexible circuits have been key enablers for this rapidly evolving industry.

The low-altitude airspace sector, encompassing drones and aerial logistics systems, represents another frontier where custom flexible PCB manufacturing is driving innovation. These applications demand the ultimate combination of lightweight design, reliability under vibration, and compact integration – all strengths of flexible circuit technology.

Flex Plus: Pioneering Excellence in Flexible PCB Manufacturing

At the forefront of this technological revolution stands Flex Plus (Xiamen) Co., Ltd., a premier professional flexible PCB manufacturer with over 20 years of experience. Since 2004, Flex Plus has been providing high-quality flexible printed circuits that empower innovation across diverse industries. As China’s leading certified flexible PCB and COB integration specialist, the company combines manufacturing excellence with cutting-edge research to create solutions that push the boundaries of what’s possible.

Flex Plus’s philosophy centers on certified excellence, innovation, and complete manufacturing control. Unlike brokers or trading companies, Flex Plus operates an 8,000+ square meter factory equipped with advanced production lines, providing full in-house manufacturing from long-format flexible PCBs to multilayer rigid-flex boards. This vertical integration ensures consistent quality and enables the rapid prototyping necessary for today’s fast-paced product development cycles.

The company’s commitment to innovation is evident in its breakthrough technologies, including flexible heat dissipation flow channels, transparent PCBs, and ultra-thin designs. By maintaining strict adherence to international standards such as ISO 9001, ISO 13485, IATF 16949, and ISO 14001, Flex Plus ensures its products meet the highest quality and environmental responsibility benchmarks.

Perhaps most significantly, Flex Plus approaches each project as an engineering partnership rather than a simple supplier relationship. Their comprehensive design support services include DFM analysis, material consultation, and technical feedback to optimize designs for manufacturability and reliability. This collaborative approach has helped over 2,500 customers across North America, South America, Europe, Japan, Taiwan, and Southeast Asia bring innovative products to market faster and more efficiently.

The Future of Custom Flexible PCB Manufacturing

As technology continues to evolve, custom flexible PCB manufacturing stands at the threshold of exciting new possibilities. Emerging trends such as stretchable electronics, embedded components, and biodegradable substrates promise to further expand the capabilities of flexible circuits. The integration of flexible PCBs with advanced technologies like 5G, Internet of Things, and artificial intelligence is creating opportunities for entirely new categories of products.

The beauty of custom flexible PCB manufacturing lies in its ability to adapt and evolve alongside technological progress. As devices become smaller, more powerful, and more integrated into our daily lives, the demand for sophisticated flexible circuits will only increase. From medical implants that monitor and respond to body conditions in real-time to foldable consumer electronics that transform between different form factors, flexible PCBs will continue to enable innovations that improve our world.

In this exciting technological landscape, manufacturers like Flex Plus (Xiamen) Co., Ltd. play a crucial role not just as suppliers but as innovation partners. By combining manufacturing expertise with forward-thinking design capabilities, they help transform ambitious concepts into practical realities. Their commitment to quality, precision, and customer service ensures that the invisible technology inside our devices works reliably day after day, year after year.

Custom flexible PCB manufacturing may remain hidden from view, but its impact on our technological world is profound and far-reaching. As we look to the future, these bendable brains will continue to power the innovations that shape how we live, work, and interact with technology.