When automotive suppliers discuss IATF 16949 certification, the conversation often starts with a simple question: “How much will this cost?” The real answer isn’t simple at all. Over 20+ years of working with automotive manufacturers, we’ve seen companies estimate $30,000 for certification only to spend $150,000 by the time they achieve it. Others budget $200,000 and complete the process for half that amount.

The difference isn’t luck. It’s understanding what you’re really budgeting for.

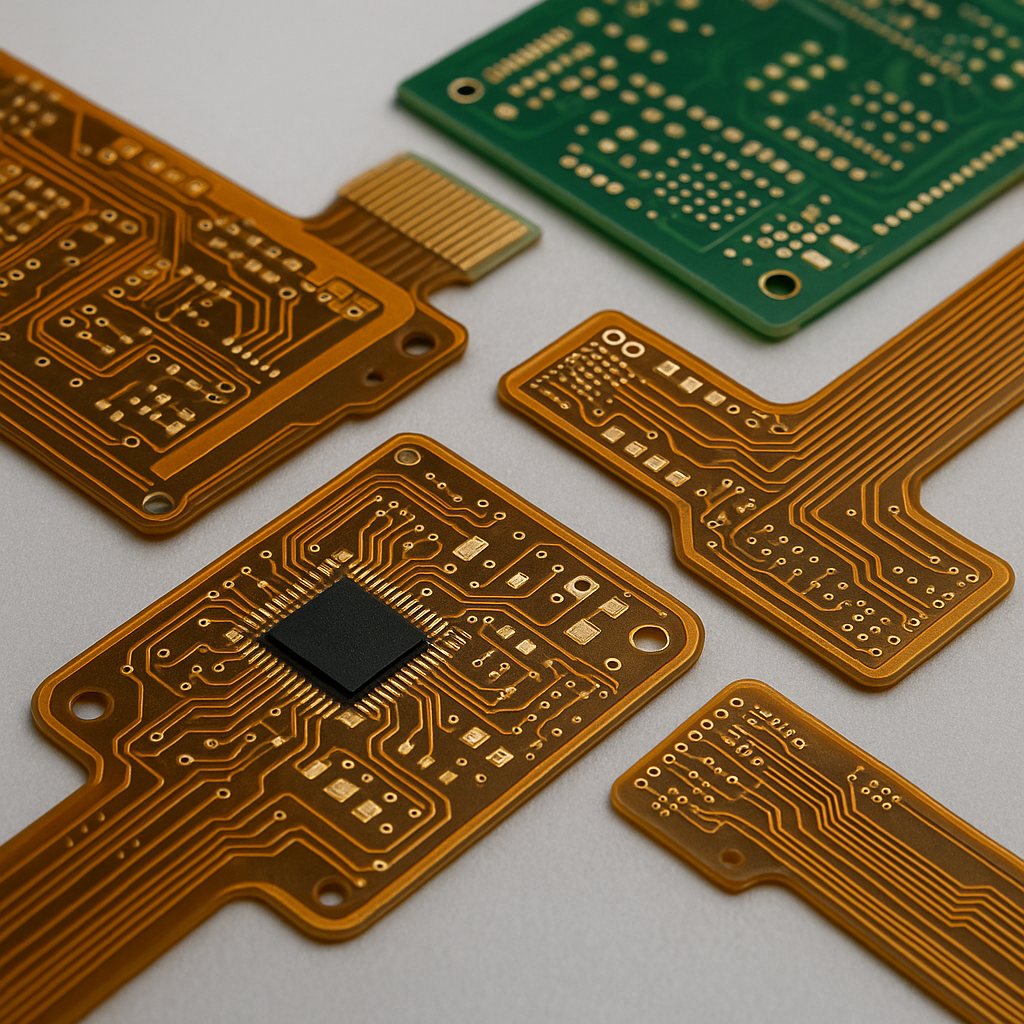

IATF 16949 represents the global quality management standard for automotive suppliers. Unlike general quality standards, it specifically addresses the unique challenges of automotive manufacturing: zero-defect expectations, complex supply chains, and the catastrophic cost of field failures. For suppliers producing flexible PCBs for electric vehicle sensors, medical-grade circuits for automotive health monitoring systems, or rigid-flex boards for advanced driver assistance systems, this certification isn’t optional—it’s the entry ticket to Tier 1 and OEM partnerships.

But that ticket has a price tag with more line items than most finance teams anticipate.

The External Costs Everyone Expects (But Often Underestimates)

Start with the obvious expenses. Certification body fees typically range from $15,000 to $45,000 for initial certification, depending on your organization’s size and complexity. A single-site manufacturer with 150 employees producing flexible circuits might pay $18,000. A multi-site operation with 800 employees across three facilities could easily reach $40,000.

These fees cover the Stage 1 document review, Stage 2 on-site audit, and certification decision. What catches companies off guard is the preparation required before the certification body arrives.

Gap analysis consultants charge $8,000 to $25,000 to evaluate your current quality management system against IATF 16949 requirements. This assessment identifies the gaps between your existing processes and what the standard demands. For a manufacturer transitioning from ISO 9001 to IATF 16949, this analysis might reveal 40-60 discrete gaps requiring correction. Each gap represents additional work—and additional cost.

Training expenses escalate quickly. Internal auditor training runs $1,200-$2,500 per person, and IATF 16949 requires trained internal auditors. With a team of five auditors, you’re looking at $6,000-$12,500 before anyone audits a single process. Core Tools training (APQP, FMEA, MSA, SPC, PPAP) adds another $3,000-$8,000. Quality managers need more extensive training, often $4,000-$7,000 for comprehensive IATF 16949 courses.

Then there’s the equipment and software nobody budgeted for. Statistical Process Control software that meets automotive industry requirements costs $5,000-$15,000. Measurement system upgrades to achieve the gauge R&R studies required by IATF 16949 can run $10,000-$50,000. If your current inspection equipment can’t demonstrate the measurement uncertainty required for safety-critical components, you’ll need to upgrade before certification is possible.

One flexible PCB manufacturer discovered their existing coordinate measuring machine couldn’t verify the ±0.05mm tolerances required for automotive connector circuits. The replacement cost $35,000—an expense completely absent from their original certification budget.

The Internal Costs That Destroy Budgets

External expenses are predictable. Internal costs are where budgets collapse.

The time commitment from your staff represents the largest hidden cost. Your quality manager might spend 40-60% of their time on certification activities for 8-12 months. That’s 800-1,200 hours of salary cost—$40,000 to $80,000 for a quality manager earning $50-80 per hour—redirected from daily operations.

Process engineers, production supervisors, and documentation specialists each contribute hundreds of hours. A typical implementation requires:

- 400-600 hours of documentation creation and updates

- 200-300 hours conducting internal audits

- 150-250 hours in management review meetings

- 300-500 hours implementing corrective actions from gap analysis

At blended rates of $35-$65 per hour, you’re looking at $70,000-$105,000 in internal labor costs for a mid-sized operation.

Documentation updates alone consume more resources than most companies anticipate. IATF 16949 doesn’t just require procedures—it requires procedures that demonstrate process approach, risk-based thinking, and automotive-specific requirements. A manufacturer with 60 existing procedures might need to revise 45 of them and create 20 new ones. Each procedure requires drafting, technical review, management review, and training. Calculate 8-12 hours per procedure, and you’re dedicating 520-780 hours just to documentation.

The productivity impact during implementation is real. Production engineers splitting time between certification preparation and daily problem-solving become less effective at both. Customer complaints don’t pause for certification activities. New product launches don’t wait. One automotive supplier saw their on-time delivery drop from 96% to 89% during their most intensive certification period because key personnel were stretched too thin.

What You’ll Actually Spend: Breaking Down the Numbers

For a single-site manufacturer with 100-200 employees, realistic total costs for initial IATF 16949 certification typically fall between $85,000 and $145,000. This includes:

- Certification body fees: $18,000-$28,000

- Consultant support: $15,000-$35,000 (if used)

- Training (internal auditors, quality team, awareness): $12,000-$22,000

- Equipment and software upgrades: $10,000-$30,000

- Internal labor (quality manager, engineers, documentation): $30,000-$50,000

After initial certification, surveillance audits occur annually at roughly 50-60% of the initial certification fee—$9,000-$17,000 per year. Every three years, you undergo recertification at costs approaching the initial certification fee.

Multi-site operations face multiplied complexity. Each additional site adds 40-60% of a single-site certification cost. A three-site manufacturer might spend $200,000-$300,000 for initial certification across all locations.

Company size dramatically influences costs. Organizations with over 500 employees often spend $175,000-$250,000 due to organizational complexity, more extensive documentation, and longer audit durations.

Process maturity matters more than many realize. If you’re currently certified to ISO 9001:2015, you’ve already addressed 70% of IATF 16949 requirements, since IATF 16949 incorporates the entire ISO 9001 standard. The automotive-specific requirements—customer-specific requirements, warranty management, embedded software management—become your focus. A manufacturer without ISO 9001 faces the full scope, potentially doubling implementation costs.

Existing quality system sophistication significantly impacts expenses. A company with mature Statistical Process Control, established APQP processes, and functioning supplier quality management spends far less than one building these capabilities from scratch.

The Five Cost Drivers That Actually Matter

The number of sites in your certification scope creates the most dramatic cost variations. Each facility requires separate auditing, documentation that addresses site-specific processes, and trained personnel. While the second and third sites cost less than the first, the scaling isn’t linear—it’s typically 60% and 50% respectively.

Process complexity directly correlates with audit duration and associated fees. Manufacturing flexible circuits with 2-4 layers involves straightforward processes. Producing 8-layer rigid-flex PCBs with controlled impedance, incorporating Chip-on-Board technology, managing thermal management solutions, and delivering medical-grade products with biocompatible materials multiplies process complexity. Each additional process step, each critical-to-quality characteristic, each special process requiring validation extends audit time and increases costs.

Documentation requirements scale with complexity. A manufacturer producing standard flexible circuits might maintain 80 procedures. One offering rigid-flex boards, TPU circuits, ultra-thin designs down to 25 microns, and transparent PCB technology could require 150+ procedures addressing each product line’s unique control requirements.

Your choice of certification body influences costs by 20-30%. The major certification bodies—like BSI, TÜV, LRQA—charge premium rates but bring recognized expertise and global reputation. Smaller bodies offer competitive pricing but may lack automotive industry depth. The cheapest option isn’t always the most cost-effective. A certification body unfamiliar with flexible PCB manufacturing might misinterpret processes, extending audit duration and increasing non-conformity findings.

The balance between internal and external resources represents the most controllable cost variable. Building internal capability requires time but reduces long-term dependence on consultants. Many successful implementations use consultants for specialized expertise—developing FMEA methodologies, establishing SPC systems, training internal auditors—while managing the overall project internally.

At Flex Plus, we chose to build robust internal capabilities rather than rely on external consultants for ongoing quality management. Our quality team underwent comprehensive IATF 16949 training, our production engineers mastered Core Tools applications, and our documentation specialists developed expertise in automotive quality requirements. This upfront investment in our people created sustainable capabilities that continue delivering value years after certification. When we expanded our rigid-flex PCB capabilities to 12-layer configurations or introduced breakthrough flexible COB technology, our team could independently develop and validate control plans meeting automotive standards.

Building a Budget That Actually Works

Start by defining your certification scope precisely. Which facilities will be certified? Which product lines fall under the scope? IATF 16949 certification applies to sites performing manufacturing, assembly, or heat treatment—not just design centers or sales offices. A company producing flexible circuits at one facility and performing final assembly at another must decide whether both sites require certification or if they can structure operations to certify only the primary manufacturing site.

Conduct a preliminary gap assessment before committing to external consultants. Many certification bodies offer pre-assessment services for $3,000-$8,000, providing a documented gap analysis that informs your budget. This assessment might reveal that your process FMEA methodology needs complete overhaul—a $25,000 project—or that minor adjustments satisfy requirements, requiring only internal resources.

Budget for both initial certification and three years of maintenance. This provides a realistic total cost of ownership view. Initial certification plus three surveillance audits might total $115,000—very different from budgeting only the $85,000 initial certification cost.

Allocate 15-20% contingency for unexpected costs. You will discover measurement equipment requiring calibration services not previously used. You will identify processes requiring validation studies not initially planned. The contingency isn’t pessimism—it’s realism based on consistent implementation experience across industries.

Strategies That Actually Reduce Costs (Without Compromising Quality)

Phase your implementation by prioritizing highest-risk areas first. Instead of addressing all 60 gap items simultaneously, focus on the 15 gaps involving safety-critical processes, customer-specific requirements, and known problem areas. This focused approach builds competence before tackling less critical requirements, reducing rework and revision cycles.

Leverage your existing ISO 9001 system if certified. Don’t recreate functional processes—enhance them with automotive-specific requirements. Your document control system likely meets 90% of IATF 16949 needs; add the required retention periods and authorization levels rather than building from scratch.

Build internal capabilities instead of maintaining long-term consultant dependence. A $15,000 investment in training five internal auditors generates $30,000-$50,000 of annual value compared to hiring external auditors repeatedly. Those trained auditors also strengthen daily operations, identifying improvement opportunities and ensuring sustained compliance.

Negotiate certification body packages covering initial certification and three years of surveillance audits. Some bodies discount bundled services by 10-15%, and fixed pricing protects against audit duration overruns.

Utilize free or low-cost resources from industry associations. The Automotive Industry Action Group (AIAG) provides extensive guidance materials, webinars, and reference documents. IATF publishes Sanctioned Interpretations clarifying requirement intent. These resources reduce consultant hours spent answering basic questions.

Select a certification body experienced with your industry sector. An auditor familiar with flexible PCB manufacturing understands process flow, recognizes appropriate control methods, and efficiently assesses technical requirements. An inexperienced auditor extends audit duration asking basic questions and potentially raising non-conformities that more knowledgeable auditors would recognize as appropriate controls. The certification body fee difference might be $3,000, but the efficiency gain saves $10,000 in internal resource time and reduces implementation frustration.

The Ongoing Costs Nobody Mentions

Surveillance audits occur annually after certification, typically 1-1.5 days on-site costing 50-60% of initial certification fees. For a $25,000 initial certification, expect $12,500-$15,000 annual surveillance costs.

Continuous improvement activities required by IATF 16949 consume ongoing resources. Clause 10.3 mandates continual improvement, not just corrective action. This requires dedicated resources analyzing quality data, implementing improvements, and documenting results. Budget 10-15% of your quality manager’s time for continual improvement activities beyond daily firefighting.

Customer-specific requirement compliance adds unique costs. Major automotive OEMs publish specific requirements supplementing IATF 16949. Meeting Ford’s customer-specific requirements differs from meeting BMW’s or Tesla’s. Each new customer potentially introduces new requirements, new training needs, and new process modifications. A supplier adding a major EV manufacturer as a customer might spend $8,000-$15,000 implementing their specific quality requirements even after IATF 16949 certification.

The Risk of Under-Budgeting (It’s More Expensive Than You Think)

Insufficient budgets create certification delays—and delays cost money beyond the obvious. Each month of delayed certification is a month you can’t bid on automotive contracts requiring certified suppliers. For a flexible PCB manufacturer, that could represent $200,000-$500,000 in unrealized revenue from automotive customers demanding certified suppliers.

Under-resourced implementations generate non-conformities during certification audits. Each non-conformity requires investigation, root cause analysis, corrective action, and follow-up verification. Minor non-conformities might delay certification by 30-60 days. Major non-conformities require full re-audit at additional cost—potentially $10,000-$20,000 and 2-3 months delay.

Rushed implementations compromise employee buy-in and understanding. When staff receive minimal training and face constant pressure to complete certification activities, they view IATF 16949 as bureaucracy rather than methodology. This undermines the quality culture the standard aims to create and leads to superficial compliance rather than genuine improvement.

One automotive supplier pushed for certification in six months with inadequate resources. They achieved certification after eight months, but their first surveillance audit six months later revealed systematic non-conformities because staff never truly understood the requirements. The remediation cost $45,000 and nearly resulted in certification suspension.

Timeline Expectations: How Long This Actually Takes

From project kickoff to certification, expect 8-12 months for a single-site manufacturer with existing ISO 9001 certification and moderate process complexity. Organizations without ISO 9001 typically require 12-18 months.

The timeline breaks down roughly as:

- Gap assessment and planning: 1-2 months

- Documentation development and process implementation: 3-6 months

- Internal auditing and management review: 1-2 months

- Certification body Stage 1 and Stage 2 audits: 1-2 months

- Non-conformity correction and certification decision: 1-2 months

Multi-site operations or highly complex processes extend timelines to 14-18 months. This isn’t because work proceeds slower—it’s because coordination across sites, ensuring consistency in implementation, and addressing site-specific challenges requires more time.

Attempting to compress timelines below these ranges typically results in incomplete implementation, higher non-conformity rates, and ultimately longer time-to-certification when including corrective action periods.

Return on Investment: Why These Numbers Actually Make Sense

IATF 16949 certification costs appear substantial until measured against benefits. Defect reduction alone often generates cost savings exceeding implementation costs within 18-24 months.

Manufacturing flexible circuits for automotive applications with 50 PPM defect rates costs approximately $125 per defect in rework, scrap, and customer management. Reducing to 20 PPM through IATF 16949-driven process improvements saves $3,750 per million circuits produced. For a manufacturer producing 2 million circuits annually, that’s $7,500 in annual savings—$37,500 over five years.

Customer and supply chain trust opens markets. Major automotive OEMs require IATF 16949 certification for potential suppliers. Without it, you don’t bid. With it, you access automotive customers potentially worth $2-5 million in annual revenue.

Operational efficiency improvements—reduced rework, better first-pass yield, optimized processes—typically improve margins by 2-4%. For a $10 million revenue manufacturer, that’s $200,000-$400,000 in improved profitability annually.

When we pursued IATF 16949 certification at Flex Plus, we viewed it as strategic investment rather than compliance cost. The structured approach to process control strengthened our capabilities in producing ultra-thin flexible circuits down to 25 microns, enhanced our rigid-flex PCB reliability up to 12 layers, and enabled breakthrough technologies like flexible COB integration with die bonding precision within ±5°. These capabilities—developed through IATF 16949’s systematic methodology—differentiate us in serving automotive customers requiring certified suppliers for electric vehicle applications, advanced driver assistance systems, and automotive health monitoring devices.

The certification cost $118,000 over nine months. The automotive customers it enabled us to serve generated $3.2 million in revenue over the following three years—and those relationships continue growing.

The Real Budget Question

The question isn’t whether IATF 16949 certification costs too much. It’s whether you’re budgeting for what actually matters: building systematic processes that consistently deliver zero-defect products while continuously improving performance.

Companies that budget adequately, invest in their people, and commit to genuine implementation see returns that dwarf costs. Those that skimp on training, rush timelines, and view certification as a paperwork exercise waste money achieving compliance that delivers no operational benefit.

The certification cost reflects the value of systematic quality management in an industry where defects aren’t just expensive—they’re potentially catastrophic. For automotive suppliers producing components that protect lives and enable mobility, that investment makes perfect sense.

The real question is: will you budget for certification, or will you budget for excellence?