The world of electronics is experiencing a fundamental shift. Gone are the days when circuits could only exist on rigid, inflexible boards. Today, TPU circuit manufacturing stands at the forefront of a revolution that’s changing how we think about electronic devices. Imagine circuits that bend with your body, stretch as you move, and feel as comfortable as the clothes you wear. This isn’t science fiction—it’s the reality of thermoplastic polyurethane-based flexible electronics.

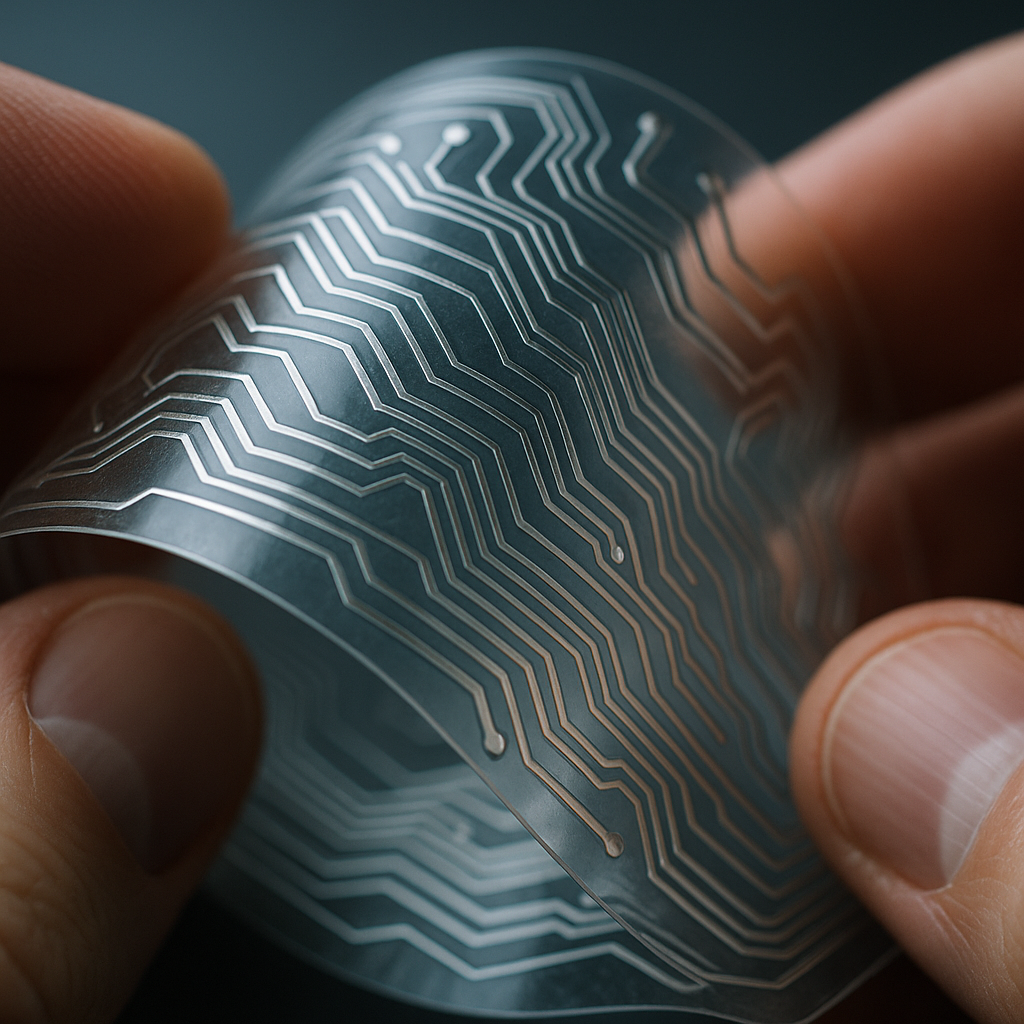

TPU circuit manufacturing uses thermoplastic polyurethane as a substrate for printed or embedded circuits, creating a new class of electronics that can flex, stretch, and conform to irregular surfaces. Unlike traditional rigid PCBs or even standard flexible circuits, TPU-based electronics offer unprecedented mechanical flexibility combined with skin-friendly properties that make them ideal for wearable applications. This technology is opening doors to innovations we could barely imagine a decade ago, from medical patches that monitor your vital signs while conforming perfectly to your skin, to athletic wear that tracks your biomechanics in real-time.

The Unique Properties That Make TPU Perfect for Flexible Circuits

When engineers at medical device companies or wearable tech startups choose materials for their next-generation products, TPU films consistently rise to the top of the list. There’s a good reason for this popularity. Thermoplastic polyurethane possesses a rare combination of properties that makes it exceptionally suitable for wearable and conformal electronics.

First and foremost, TPU is remarkably skin-friendly. Unlike some synthetic materials that can cause irritation during prolonged contact, TPU’s biocompatibility makes it suitable for medical-grade applications and all-day wearables. This property becomes crucial when you’re designing a continuous glucose monitor or a cardiac rhythm patch that patients will wear for days or weeks at a time.

The material’s durability stands out as another key advantage. TPU films can withstand repeated compression, flexing, and stretching without losing their structural integrity or electrical performance. Picture an athletic shoe with embedded pressure sensors—those sensors need to survive millions of compression cycles while maintaining accurate readings. TPU handles this challenge with ease, making it the material of choice for high-performance sports applications.

Flexibility and stretchability define TPU’s mechanical character. While standard flexible PCBs might bend in one direction, TPU-based circuits can accommodate multi-directional movements and even stretch up to 600% in some formulations. This extraordinary stretchability enables entirely new product categories, from smart textiles that move naturally with your body to conformable patches that maintain intimate contact with curved anatomical surfaces.

However, honesty requires acknowledging TPU’s limitations. The material faces challenges with high-temperature resistance compared to traditional polyimide substrates. Processing temperatures must be carefully controlled, typically staying below 240°C to avoid material degradation. Additionally, achieving strong ink adhesion on TPU’s smooth surface presents engineering challenges that demand specialized surface treatments and carefully formulated conductive inks.

Printing Techniques That Bring TPU Circuits to Life

Creating functional circuits on TPU substrates requires sophisticated printing and patterning approaches. The manufacturing process differs significantly from traditional PCB fabrication, demanding specialized equipment and techniques optimized for flexible substrates.

Inkjet printing has emerged as a popular method for TPU circuit manufacturing, offering excellent resolution for creating fine circuit traces. This digital printing technique allows designers to rapidly prototype new designs without the need for expensive tooling. By precisely depositing conductive ink droplets onto the TPU surface, manufacturers can create complex circuit patterns with line widths down to 50 micrometers. The process works particularly well for low-volume production and rapid design iterations.

Screen printing provides another proven approach, especially valued for its cost-effectiveness in medium to high-volume production. This technique uses a mesh screen to transfer conductive paste onto the TPU substrate, creating thicker conductive traces that can handle higher current loads. Screen printing excels at producing robust circuits for applications like heating elements in therapeutic patches or power distribution in wearable electronics.

Aerosol-jet printing represents the cutting edge of TPU circuit manufacturing. This technique atomizes conductive ink into a focused aerosol stream, enabling precise deposition on three-dimensional surfaces. The technology proves invaluable for creating circuits on pre-formed TPU components or adding traces to curved substrates. Aerosol-jet printing can achieve feature sizes as small as 10 micrometers, pushing the boundaries of what’s possible in flexible electronics.

Surface pretreatment plays a critical role in all these printing methods. TPU’s smooth, low-surface-energy characteristics can hinder ink adhesion, leading to poor electrical performance or circuit failure during flexing. Manufacturers address this challenge through various pretreatment techniques, including plasma treatment, corona discharge, or chemical primers. These treatments increase surface energy and create better mechanical anchoring points for conductive materials, dramatically improving adhesion and line definition. At Flex Plus, our 20+ years of experience in flexible circuit manufacturing has taught us that proper surface preparation often determines the difference between a circuit that fails after a hundred bending cycles and one that performs reliably through millions.

The Chemistry of Conductivity: Materials That Make Circuits Work

The conductive materials used in TPU circuit manufacturing must balance electrical performance with mechanical flexibility. This balance requires careful formulation and selection of inks, adhesives, and encapsulation materials.

Silver-based conductive inks dominate TPU circuit manufacturing due to their excellent electrical conductivity, flexibility, and compatibility with low-temperature processing. These inks typically contain silver nanoparticles or microflakes suspended in a polymer binder system that remains flexible after curing. The silver particles create conductive pathways while the binder maintains adhesion to the TPU substrate and provides mechanical flexibility.

Engineers can select from various silver ink formulations depending on application requirements. Some inks cure at room temperature through solvent evaporation, making them suitable for temperature-sensitive applications. Others require thermal curing at temperatures between 120°C and 150°C to achieve optimal conductivity. The choice depends on the specific TPU formulation being used and the performance requirements of the final circuit.

Conductive adhesives serve dual purposes in TPU circuits—they create electrical connections and provide mechanical bonding. These materials typically combine silver particles with flexible adhesive polymers, allowing them to attach components while maintaining electrical conductivity. The best conductive adhesives for TPU applications maintain performance through repeated flexing and environmental exposure, withstanding temperature variations, humidity, and mechanical stress.

Encapsulation represents the final critical material layer in TPU circuit manufacturing. Protective coatings shield conductive traces from oxidation, moisture, and mechanical damage while maintaining the circuit’s flexibility. Modern encapsulation materials use flexible polymers that move with the substrate without cracking or delaminating. Some advanced formulations provide selective permeability, allowing moisture vapor to escape while blocking liquid water—a crucial feature for wearable applications where perspiration management matters.

The durability of these material interfaces determines the long-term reliability of TPU circuits. Bending cycles, environmental exposure, and mechanical stress all challenge the adhesion between layers. Manufacturers enhance durability through careful material selection, optimized curing processes, and sometimes mechanical interlocking features that supplement chemical adhesion.

From Concept to Reality: TPU Device Architectures

TPU circuit manufacturing enables diverse device architectures, each optimized for specific applications and performance requirements. Understanding these architectures helps designers choose the right approach for their products.

Flexible printed circuits represent the simplest TPU-based architecture. These single or double-layer circuits feature conductive traces printed directly onto TPU films, creating thin, flexible electronics ideal for applications requiring basic sensing or connectivity. Medical patches monitoring heart rhythm or muscle activity often use this architecture, leveraging TPU’s skin-friendly properties and the circuit’s minimal thickness.

Stretchable electronics push the boundaries further, incorporating circuit designs that accommodate significant elongation. These devices use serpentine or horseshoe-shaped trace patterns that unfold as the substrate stretches, maintaining electrical conductivity even at high strain levels. Imagine a smart sleeve that stretches to fit different arm sizes while continuing to monitor muscle activity—that’s the power of truly stretchable TPU circuits.

Hybrid approaches combine flexible TPU substrates with rigid components, offering an optimal balance between functionality and flexibility—similar to rigid-flex hybrid circuits used in advanced electronics. A smart bandage might feature a rigid section housing a microcontroller and battery, connected to flexible TPU circuits with embedded sensors that conform to the wound site. This architecture provides sophisticated processing power while maintaining comfort and conformability where it matters most.

Some advanced TPU devices integrate multiple material layers, creating three-dimensional circuit structures. These multilayer designs stack conductive traces separated by insulating TPU layers, enabling complex circuit routing in minimal footprint. The approach proves valuable for applications requiring high circuit density, such as advanced wearable ECG monitors or smart textiles with distributed sensor arrays.

Connecting the Pieces: Assembly Methods That Work

Creating functional TPU-based devices requires reliable methods for interconnecting circuits and components. The inherent flexibility of TPU substrates demands connection approaches that maintain electrical and mechanical integrity through repeated flexing.

Flexible connectors designed specifically for TPU circuits provide robust mechanical and electrical connections. Zero insertion force (ZIF) connectors allow easy mating and unmating without stressing the flexible circuit, while crimp connectors create gas-tight connections through mechanical pressure. These connectors must withstand the same flexing cycles as the circuit itself, requiring careful selection based on application requirements.

Adhesiveless approaches have gained popularity for their simplicity and reliability. These methods create electrical connections through mechanical pressure or intricate mechanical interlocking, eliminating concerns about adhesive degradation over time. Z-axis conductive tape represents one such solution, containing conductive particles that create electrical pathways under compression while remaining insulating in the x and y directions. This technology elegantly connects TPU circuits to rigid boards or other flexible sections.

Direct component mounting on TPU substrates presents unique challenges. Traditional soldering often isn’t feasible due to TPU’s low melting point, driving development of alternative assembly methods. Conductive adhesives, anisotropic conductive films, and low-temperature soldering alloys provide viable solutions for attaching surface-mount components to TPU circuits. Each method offers different trade-offs between assembly temperature, electrical performance, and mechanical reliability.

Reliability factors become paramount in TPU circuit assembly. The material’s elasticity, while advantageous for flexibility, can create challenges during assembly and operation. Connection points experience concentrated stress during bending, potentially causing mechanical failure or electrical discontinuity. Designers must carefully consider stress relief features, reinforcement zones, and connection placement to maximize product longevity.

At Flex Plus, our comprehensive assembly services extend to TPU circuits, leveraging our ISO-certified processes to ensure reliable connections through advanced techniques optimized for flexible substrates. Our experience with diverse applications—from medical devices to automotive sensors—has taught us that successful TPU circuit assembly requires understanding not just electrical requirements but also the mechanical environment the device will face throughout its lifetime.

Real-World Impact: Applications Transforming Industries

TPU circuit manufacturing is moving from laboratory curiosity to commercial reality across multiple industries. The technology’s unique capabilities are enabling products that would be impossible with conventional electronics.

Wearables represent the most visible application of TPU circuits. Fitness trackers with TPU-based heart rate sensors conform comfortably to wrists while delivering accurate readings during intense activity. Smart clothing with embedded TPU circuits monitors biomechanics for athletes, providing real-time feedback on posture, muscle activation, and movement patterns. These applications leverage TPU’s skin-friendliness and flexibility to create electronics that users forget they’re wearing.

Medical sensors built on TPU substrates are revolutionizing patient monitoring. Continuous glucose monitors using TPU circuits adhere gently to skin for days at a time, providing diabetic patients with unprecedented insight into their glucose levels. Cardiac monitoring patches detect arrhythmias while patients continue their normal activities, enabled by TPU’s flexibility and biocompatibility. These devices improve patient outcomes while reducing healthcare costs through earlier intervention and reduced hospital stays.

Consumer electronics increasingly incorporate TPU circuits for enhanced functionality and user experience. Smartphone cases with integrated NFC antennas and LED displays use TPU circuits to add features without sacrificing device protection. Gaming controllers with pressure-sensitive grips employ TPU sensors to provide more immersive interaction. Even augmented reality wearables and AI glasses benefit from TPU’s ability to create comfortable, conformable electronics.

Automotive applications represent a growing market for TPU circuits. Electric vehicles use flexible TPU-based sensors throughout cabin interiors, detecting occupant position for optimal airbag deployment. Dashboard controls with integrated TPU circuits provide tactile feedback while conforming to curved surfaces. As vehicles become more electrified and connected, demand for flexible, durable TPU circuits continues to accelerate.

Overcoming Obstacles: Challenges and Solutions

Despite impressive advances, TPU circuit manufacturing faces challenges that researchers and manufacturers are actively addressing. Understanding these obstacles helps set realistic expectations and guides future development.

Adhesive improvements top the list of needed advances. While current conductive inks and adhesives work adequately, they don’t always match the stretchability of TPU substrates. This mismatch can cause cracks in conductive traces during extreme flexing or stretching. Researchers are developing new formulations that better match TPU’s mechanical properties, including liquid metal composites that maintain conductivity even under high strain.

Thermal management presents another significant challenge. TPU’s limited temperature resistance restricts component selection and operating conditions. Applications involving significant heat generation require careful thermal design, sometimes incorporating materials with higher thermal conductivity alongside TPU sections. Advanced encapsulation materials that enhance heat dissipation while maintaining flexibility represent one promising solution direction.

Scalable production strategies are essential for bringing TPU circuits from prototype to mass market. Roll-to-roll printing offers the most promising path to high-volume manufacturing, processing continuous TPU films through sequential printing and curing stations. This approach dramatically reduces production costs while maintaining quality consistency. However, implementing roll-to-roll processing for TPU circuits requires specialized equipment and process control to handle the material’s unique properties.

Large-area manufacturability remains challenging. Creating uniform circuits across multi-meter TPU substrates demands precise tension control, temperature management, and printing registration. Manufacturers like Flex Plus are addressing these challenges through advanced equipment and process expertise, enabling production of TPU circuits up to 600mm in length with consistent quality throughout.

The Road Ahead: Future Directions and Innovations

The future of TPU circuit manufacturing looks remarkably bright, with numerous innovations on the horizon that will expand capabilities and applications.

Stretchable circuit concepts continue advancing, with researchers developing new trace geometries and materials that maintain electrical performance through extreme deformation. Some emerging designs incorporate self-healing materials that repair minor damage, potentially creating circuits that maintain functionality even after punctures or tears. These advances will enable wearables that truly move and stretch with the body without compromising performance.

Durable interconnects represent another critical development area. New connection technologies maintain electrical and mechanical integrity through millions of flex cycles, using innovative geometries and material combinations. Some approaches draw inspiration from biological systems, mimicking how natural tissues distribute stress to prevent failure. These bio-inspired interconnects could dramatically extend product lifespans while reducing warranty costs.

Integration with soft robotics opens entirely new application frontiers. TPU circuits provide the nervous system for soft robots that safely interact with humans and navigate complex environments. Imagine robotic surgical tools that gently conform to tissue while providing precise control, or assistive devices that adapt naturally to user movements. These applications demand circuits that match soft materials’ compliance while delivering sophisticated sensing and control capabilities.

Advanced materials combining TPU with other functional polymers promise enhanced performance. Composite substrates might offer better thermal management, higher electrical conductivity, or improved optical properties while maintaining TPU’s flexibility and biocompatibility. These materials will enable new applications we haven’t yet imagined.

At Flex Plus, our commitment to innovation aligns perfectly with this advancing frontier. Our 20+ years of flexible PCB manufacturing experience, combined with our cutting-edge TPU circuit capabilities, positions us to help customers navigate this exciting technology landscape. We understand that stretchable electronics aren’t just about making circuits flexible—they’re about reimagining what electronics can be and where they can go.

The convergence of TPU circuit manufacturing with emerging technologies like AI, IoT, and advanced materials science promises a future where electronics seamlessly integrate into every aspect of our lives. From medical devices that disappear into our bodies to wearables that feel like second skin, TPU circuits are making possible the electronic devices of tomorrow. The revolution in stretchable electronics isn’t coming—it’s already here, transforming products across industries and improving lives in ways we’re only beginning to appreciate.