When Sarah, a senior design engineer at a leading medical device manufacturer, first proposed replacing traditional connector-based assemblies with rigid-flex PCBs, her procurement team was skeptical. Six months later, their new product achieved a 40% size reduction and passed reliability testing with zero interconnection failures. Stories like Sarah’s are becoming increasingly common as engineers across industries discover the transformative advantages of integrated rigid-flex solutions.

The shift from connector-dependent designs to integrated rigid-flex circuit boards represents more than just a manufacturing trend—it marks a fundamental change in how we approach electronic product development. For over two decades, we at Flex Plus have witnessed this evolution firsthand, working alongside design teams who recognize that eliminating mechanical connections isn’t just about saving space; it’s about building better, more reliable products from the ground up.

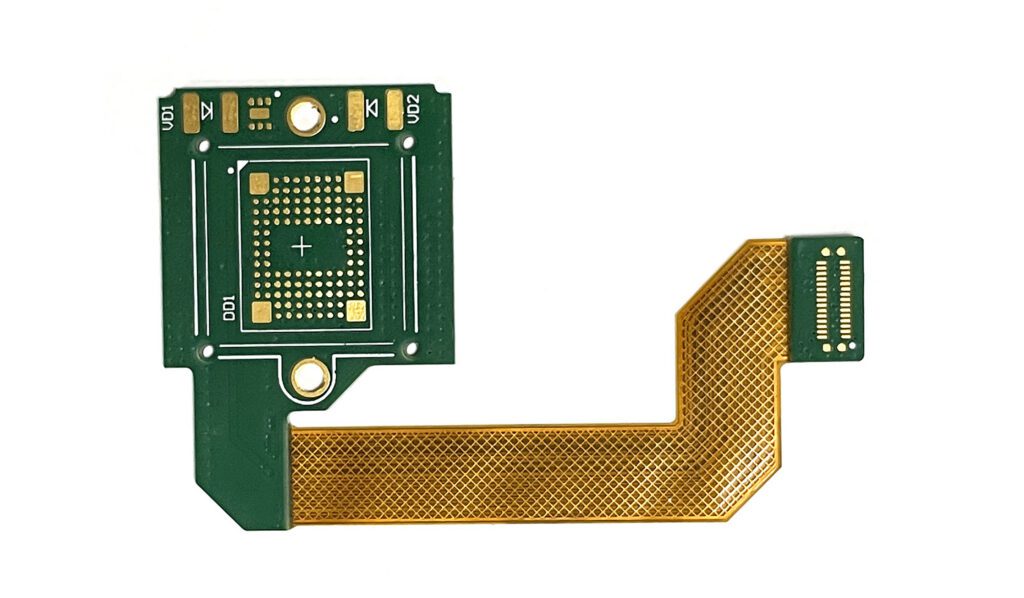

Understanding the Hybrid Architecture

At its core, a rigid flexible PCB combines the best of two worlds. Picture a circuit board where rigid sections provide structural support and component mounting areas, while flexible sections enable three-dimensional configurations and movement. This hybrid construction eliminates the traditional need for connectors, cables, and multiple separate boards that must be mechanically joined.

The structure itself tells a story of thoughtful engineering. The rigid portions typically use FR-4 material, the industry-standard fiberglass-reinforced epoxy that provides robust mechanical strength for heavier components like processors, power management ICs, and connector interfaces. These sections maintain their shape permanently, offering the stability that sensitive components require during assembly and throughout the product’s operational life.

Between these rigid islands, flexible sections crafted from polyimide (PI) create bendable pathways that conform to product contours. Polyimide offers exceptional thermal stability, maintaining electrical performance across temperature ranges that would compromise lesser materials. When you need circuits that bend thousands of times without failure—think foldable smartphones or medical implants—polyimide’s mechanical resilience becomes non-negotiable.

The magic happens in the transition zones where rigid meets flexible. These areas require careful attention during design. Engineers must account for stress concentrations that occur at bend points, ensuring copper traces don’t crack under repeated flexing. Material selection extends beyond the obvious substrate choices to include adhesives, bond plies, and coverlays that protect and insulate conductors while maintaining flexibility.

Getting these material selections right demands more than theoretical knowledge. It requires understanding how different materials behave during manufacturing processes, how they respond to environmental stresses, and how they’ll perform over the product’s entire lifecycle. This is where early collaboration with experienced manufacturers becomes invaluable. At Flex Plus, we’ve seen countless designs improved through early-stage material consultations that align theoretical requirements with manufacturing realities.

The Compelling Advantages That Drive Adoption

The benefits of rigid-flex PCBs extend far beyond the obvious elimination of connectors. When automotive electronics teams design sensor arrays for electric vehicles, space constraints become critical. Every millimeter matters when you’re integrating sophisticated electronics into increasingly compact vehicle architectures. Rigid-flex designs can reduce overall assembly volume by up to 60% compared to equivalent connector-based solutions, creating room for additional features or simply enabling sleeker product designs.

Weight savings follow naturally from space reduction, but the impact varies dramatically by application. In aerospace systems where every gram affects fuel efficiency and payload capacity, replacing multiple rigid boards and their interconnecting cables with a single rigid-flex assembly delivers measurable performance improvements. We’ve worked with aerospace contractors who achieved 30-40% weight reductions in avionics assemblies through strategic rigid-flex implementations.

Reliability improvements might be the most compelling advantage of all. Consider that traditional multi-board assemblies rely on connectors as their weakest link. Every connector introduces potential failure points—pins that can corrode, sockets that can loosen, contacts that oxidize over time. Industry studies consistently show that interconnections account for the majority of electronic failures in harsh environments.

Rigid-flex PCBs eliminate up to 87% of these interconnection points. For medical device manufacturers developing implantable electronics or life-critical monitoring systems, this reliability enhancement isn’t just a nice-to-have—it’s essential. When device failure could mean patient harm, the inherent reliability of integrated connections becomes a decisive factor in design decisions.

Signal integrity improvements often surprise engineers new to rigid-flex technology. Eliminating connectors means eliminating impedance discontinuities that cause signal reflections and degrade high-frequency performance. For telecommunications equipment manufacturers building optical transceivers operating at multi-gigabit data rates, maintaining signal quality across board transitions directly impacts product performance specifications.

The three-dimensional design freedom that rigid-flex enables opens entirely new approaches to product architecture. Rather than constraining electronics to fit on planar boards connected by cables, designers can fold circuits to follow product contours, wrap them around mechanical structures, or stack them vertically in tight spaces. This freedom transforms how we conceptualize electronic packaging, enabling innovations in folding electronics design that would be impractical or impossible with traditional approaches.

Navigating Design and Manufacturing Challenges

The transition to rigid-flex designs isn’t without challenges. Engineers accustomed to rigid PCB design rules quickly discover that flex sections require different thinking. Trace routing that works perfectly on rigid boards may create stress risers that lead to copper cracking when those same traces must bend repeatedly.

Design rule considerations multiply when working with flexible materials. Minimum bend radius requirements become critical specifications that directly impact reliability. Bend too sharply, and you risk copper fracture during flexing. The bend radius varies with substrate thickness, copper weight, and the number of flex layers, requiring careful calculation rather than rules of thumb.

Layer stack-up decisions grow more complex when combining rigid and flexible sections. How many flex layers do you need? Should they be continuous through the rigid sections or terminated? Where should you locate ground and power planes for optimal shielding without sacrificing flexibility? These questions don’t have universal answers—they depend on electrical requirements, mechanical constraints, and manufacturing capabilities.

Material selection extends beyond choosing polyimide for flex sections and FR-4 for rigid portions. Adhesive systems matter tremendously. Should you use adhesive-based constructions for lower cost or adhesiveless approaches for better high-frequency performance? What copper weight serves your current requirements without making the assembly too stiff to flex properly? These decisions cascade through the entire design, affecting everything from electrical performance to manufacturing yields.

The complexity of these decisions underscores why early manufacturer engagement proves so valuable. At Flex Plus, we conduct comprehensive Design for Manufacturing (DFMEA) analyses that identify potential manufacturing issues before prototyping begins. This upfront collaboration prevents costly iterations and accelerates time to market. When engineers can discuss their designs directly with production engineers who will build them, designs improve in ways that benefit everyone.

Compliance requirements add another layer of complexity. Medical device manufacturers need ISO 13485-certified processes. Automotive applications require IATF 16949 compliance. Aerospace and defense projects demand specialized certifications and traceability. Selecting a manufacturing partner with the necessary certifications isn’t just about checking boxes—it’s about ensuring your product meets industry standards from day one rather than discovering compliance issues during qualification testing.

Emerging Innovations Shaping the Future

The rigid-flex PCB landscape continues evolving rapidly. High-Density Interconnect (HDI) techniques once reserved for rigid boards are migrating to flexible substrates, enabling trace widths and spacings down to 2mil/2mil (0.05mm/0.05mm). This density transformation enables integration levels that seemed impossible just years ago, fitting sophisticated electronics into wearable devices, medical implants, and miniaturized sensors.

Additive manufacturing techniques are beginning to complement traditional subtractive processes. While conventional PCB fabrication removes copper to create traces, additive approaches build up conductors precisely where needed. This precision opens possibilities for even finer features and unique three-dimensional conductor geometries that optimize signal routing in ways that planar processes can’t achieve.

Thermal management innovations address one of flexible electronics’ persistent challenges. Traditional rigid PCBs use copper planes and thermal vias to dissipate heat, but these approaches add stiffness that defeats flexibility. Pioneering manufacturers are developing flexible heat dissipation flow channels and proprietary thermal pathway technologies that move heat efficiently while maintaining mechanical flexibility—critical for high-power LED applications and automotive electronics subjected to significant thermal cycling.

Transparent PCB technology represents another frontier. Imagine circuits with 90%+ transparency that can integrate directly into display assemblies or augmented reality headsets without obscuring optical paths. These breakthrough materials maintain electrical performance while offering exceptional optical clarity, enabling entirely new product categories in consumer electronics and wearables.

At Flex Plus, our investment in these emerging technologies stems from a commitment to partnership rather than just manufacturing. When clients approach us with ambitious concepts pushing current technology boundaries, we don’t simply quote their designs—we collaborate to refine them. Our 20+ years of specialized experience has taught us that the best products emerge from genuine engineering partnerships where manufacturer expertise shapes designs from their earliest stages.

This collaborative approach extends through our comprehensive service model. Rather than stopping at bare PCB fabrication, we offer complete Flex PCBA services including component sourcing, automated placement, reflow soldering, and rigorous testing. This end-to-end capability reduces vendor count and production delays while minimizing quality issues that arise when multiple vendors must interface across handoff points.

The Strategic Advantage of Going Integrated

The engineers who are ditching connectors for integrated rigid-flex solutions aren’t just following trends—they’re making strategic decisions that deliver measurable competitive advantages. Products become more reliable, smaller, and lighter while often achieving better electrical performance. Assembly processes simplify, reducing manufacturing costs even when the PCBs themselves carry premium prices.

The decision to adopt rigid-flex technology requires investment—in new design skills, potentially longer prototype cycles as teams master new techniques, and usually higher per-unit PCB costs compared to simple rigid boards. But recognize that these upfront investments pay dividends throughout the product lifecycle through reduced warranty costs, simplified assembly, and enhanced product capabilities that differentiate their offerings in competitive markets.

Success with rigid-flex technology hinges on partnership with manufacturing experts who understand both the possibilities and the practical constraints. Engineers need manufacturers who can provide frank guidance about what’s feasible, what’s cost-effective, and what alternatives might better serve specific requirements. They need direct communication with production engineers rather than layers of sales intermediaries. And they need flexible lead times that accommodate the realities of product development, where urgent prototype iterations can make the difference between meeting market windows and missing opportunities.

The future of electronic product development increasingly points toward integrated solutions that eliminate unnecessary complexity while enhancing reliability and performance. Rigid-flex PCB technology stands at the forefront of this evolution, enabling innovations across industries from electric vehicles to medical implants to next-generation consumer electronics. As more engineers discover these advantages through hands-on experience, the momentum toward integrated solutions will only accelerate.

For companies ready to explore rigid-flex possibilities, the journey begins with conversation. At Flex Plus, we’ve built our reputation on turning ambitious concepts into production realities, guided by certifications including ISO 9001, ISO 13485, IATF 16949, and ISO 14001 that demonstrate our commitment to quality and excellence. Our state-of-the-art facility provides end-to-end control from raw materials to final assembly, ensuring consistent quality and eliminating the uncertainty that comes with broker arrangements.

Whether you’re developing next-generation wearables, life-critical medical devices, or cutting-edge automotive electronics, integrated rigid-flex solutions offer advantages that traditional connector-based approaches simply cannot match. The question isn’t whether to consider rigid-flex technology—it’s whether you can afford not to.