Picture this: A promising medical device prototype works perfectly in the lab, passes initial testing, and moves into production. Six months later, field reports reveal intermittent failures. Engineers trace the problem back to a single overlooked detail—the flexible PCB connector choice. This scenario plays out more often than you’d think across industries from electric vehicles to aerospace systems.

The truth is, your product’s reliability hinges on decisions made early in the design phase. When it comes to flexible circuits, the interconnect solution you select can mean the difference between market success and costly recalls. For companies developing next-generation technologies—whether it’s an eVTOL air taxi, a precision medical implant, or an augmented reality headset—understanding flexible PCB connectors isn’t optional. It’s essential.

Think of flexible PCB connectors as the handshake between different parts of your electronic system. Just as a weak handshake undermines trust in a business relationship, a poorly chosen connector undermines your entire product architecture. These tiny components carry signals, power, and data between flexible circuits and other boards or systems. When they fail, everything fails.

The stakes are particularly high in industries where FlexPlus serves customers. An automotive manufacturer deploying IATF 16949-certified flexible circuits in electric vehicle battery management systems can’t afford connector failures that might trigger safety recalls. A medical device company using ISO 13485-certified biomedical-compatible flex PCBs needs absolute reliability when lives depend on consistent device performance. The connector isn’t just a component—it’s a promise of reliability to your end users.

Understanding Your Flexible PCB Connector Options

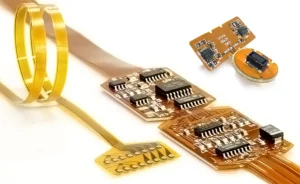

Let’s break down the main types of flexible PCB connectors you’ll encounter. Each serves specific purposes, and choosing the wrong one is like trying to fit a square peg in a round hole.

Zero Insertion Force (ZIF) connectors are the gentle giants of the flexible circuit world. These connectors feature a movable actuator that clamps down on the flexible cable once it’s positioned. There’s no force required during insertion, which protects delicate flexible circuits from stress damage. ZIF connectors shine in applications requiring frequent connection and disconnection. According to industry guidance on Zero Insertion Force connectors, these mechanisms protect delicate circuits during repeated testing cycles. Think about smartphone manufacturers who need to test multiple prototypes rapidly. The flip-up actuator allows engineers to swap FPC cables dozens of times without wearing out the circuit or connector.

Low Insertion Force (LIF) connectors require slight pressure to insert the flexible circuit, but significantly less than traditional connectors. They offer a middle ground—easier insertion than standard connectors while being more compact and cost-effective than ZIF designs. LIF connectors work well in consumer electronics where space is tight and the connection only needs to be made once during assembly. Smart helmet manufacturers, for instance, might use LIF connectors to link sensor arrays to processing units in F1 racing applications where vibration resistance matters more than repeated connections.

Flat Flexible Cable (FFC) connectors specifically mate with flat flexible cables that have exposed conductors along one edge. These connectors typically feature a simple clamping mechanism and take up minimal board space. The telecommunications industry relies heavily on FFC connectors in optical transceiver modules where multiple signal paths run in parallel. The flat profile allows dense circuit routing in rack-mounted equipment where every millimeter of vertical space counts.

Flexible Printed Circuit (FPC) connectors differ from FFC connectors in that they’re designed for flexible circuits with covered conductors. FPC circuits have a protective coverlay over the copper traces, requiring connector contacts to penetrate or compress the circuit rather than making surface contact. These connectors appear throughout industrial control systems where environmental protection is critical. The coverlay shields sensitive traces from contamination while the connector maintains reliable contact.

Board-to-Board (BTB) connectors directly link a flexible circuit to another PCB without intermediate cables. This approach eliminates separate cable assemblies entirely, reducing potential failure points and assembly time. Drone manufacturers developing low-altitude airspace technologies appreciate BTB connectors because they eliminate the weight and complexity of cable harnesses while withstanding flight vibrations. When every gram matters for flight time, integrating the flexible circuit directly into the connector strategy pays dividends.

Each connector type brings distinct advantages. Understanding these nuances is essential for avoiding critical design mistakes that compromise reliability. The question isn’t which is “best” universally—it’s which best serves your specific application constraints.

Critical Factors in Connector Selection

Choosing the right flexible PCB connector requires balancing multiple technical and practical considerations. Let’s walk through the decision framework that separates successful products from failed prototypes.

Manufacturability shapes your entire production strategy. A connector that’s perfect on paper but impossible to assemble reliably at scale becomes a production nightmare. Consider assembly automation. Can your pick-and-place equipment handle the connector pitch and height? Will your operators need specialized training or tools? One aerospace manufacturer discovered too late that their chosen micro-pitch connector required manual inspection under microscope—feasible for five units, unworkable for five thousand. At FlexPlus, we’ve seen this pattern repeatedly. Customers who involve manufacturing engineers early in connector selection avoid costly redesigns when scaling from prototype to production.

Reliability encompasses both electrical and mechanical longevity. Your connector must maintain signal integrity through thousands of mating cycles, temperature swings, and environmental stresses specific to your application. Beauty tech gadgets using flexible circuits designed for dynamic bending need connectors that survive repeated folding as users open and close cosmetic analysis devices. Mining smart helmets require connectors that maintain contact despite constant vibration and occasional impacts. The reliability equation changes dramatically across applications. A medical device connector might prioritize biocompatibility and sterilization resistance, while an EV connector must withstand automotive temperature extremes from -40°C to 125°C.

Contact resistance tells you whether your signals will degrade over time. Gold-plated contacts resist oxidation better than tin, but cost more. For detailed insights on termination methods and connector specifications, designers should consult comprehensive PCB design resources. For high-frequency applications in AR wearables or AI glasses, even small impedance mismatches cause signal reflection and data errors. Meanwhile, power connections in industrial automation systems need contacts that handle current without overheating. The connector you choose must match your electrical requirements not just initially, but throughout the product’s lifecycle as contacts experience micro-movements and environmental exposure.

Space constraints often drive the entire design conversation. In compact electronics like precision smartphone modules, connector height might be more critical than footprint. A connector that saves two millimeters of Z-axis height enables thinner product profiles that customers notice. Conversely, drone flight controllers might prioritize connector footprint to minimize board size while accepting greater height. Engineers developing eVTOL systems for air taxis face even tighter constraints—every cubic centimeter impacts payload capacity and flight range. The spatial efficiency of BTB connectors explains their popularity in these weight-sensitive applications.

Consider the three-dimensional implications. Flexible circuits bend, twist, and route through complex assemblies. Your connector placement and type must accommodate the intended bend radius and mechanical stresses. A right-angle connector might solve a routing challenge that a vertical connector makes impossible. Some applications need connectors on both sides of the board for clearance reasons. FlexPlus frequently works with customers to map flex circuit routing paths early in design, ensuring connector locations support both electrical and mechanical requirements.

Durability requirements vary enormously by application. Consumer electronics might need 25-50 mating cycles. Test equipment requires hundreds. Industrial systems demand thousands of insertions without contact degradation. The actuator mechanism itself represents a potential failure point—plastic actuators wear differently than metal ones. Spring contacts experience fatigue over repeated compression. Evaluate the connector’s rated mating cycles against your worst-case usage scenario, then add safety margin.

Environmental sealing becomes critical in harsh conditions. Telecommunications infrastructure exposed to outdoor weather needs sealed connectors that exclude moisture and contaminants. Medical devices undergo repeated sterilization cycles that degrade unsealed connections. Even consumer applications face environmental challenges—smartphone water resistance ratings require sealed FPC connectors between the camera module and main board. Your connector selection must account for both the operational environment and any manufacturing processes like conformal coating or potting that might affect connector performance.

The Hidden Benefits of Quality Flexible PCB Connectors

Choosing the right flexible PCB connector delivers advantages that extend far beyond basic connectivity. These benefits compound over your product’s lifecycle, affecting everything from development speed to customer satisfaction.

Design flexibility unlocks innovation. When engineers trust their interconnect solution, they explore more ambitious architectures. Consider how rigid-flex PCBs with integrated BTB connections enable three-dimensional circuit assemblies impossible with traditional connectors and cables. Medical device designers create compact implantable sensors by folding flexible circuits into millimeter-scale packages. The connector doesn’t just join circuits—it enables entirely new form factors.

FlexPlus recently worked with a client developing wearable health monitors where the flexible circuit needed to conform to the user’s wrist curvature. Standard connectors would have created rigid stress points. Instead, we designed a solution using flexible substrate COB technology integrated with specialized low-profile connectors. The resulting device achieved unprecedented comfort and reliability because the interconnect strategy supported rather than constrained the innovative design.

Enhanced reliability reduces lifetime costs dramatically. Field failures don’t just damage your reputation—they create cascading expenses. Warranty claims, technical support calls, repair logistics, and potential liability issues all stem from reliability failures. When a flexible PCB connector fails in an electric vehicle’s head-up display system, the fix might require dashboard removal and hours of dealer labor. That connector might cost five dollars, but the failure costs hundreds in warranty expense and customer goodwill.

Quality connectors prevent these scenarios. Gold-plated contacts resist corrosion through years of thermal cycling. Robust actuators maintain clamping force despite mechanical stress. Proper connector selection frontloads costs during development but eliminates much larger downstream expenses. This is why FlexPlus emphasizes certified excellence—our ISO 9001, ISO 13485, and IATF 16949 certifications ensure consistent quality that reduces your risk.

Space efficiency enables competitive advantages. Modern electronics compete on dimensions as much as features. Smartphone manufacturers tout thickness reductions measured in tenths of millimeters. Drone builders obsess over weight savings that translate to flight time. Medical device companies need smaller implants for less invasive procedures. The right flexible PCB connector contributes to all these goals.

Consider the difference between a traditional wire harness with discrete connectors versus a rigid-flex PCB with integrated BTB connections. The rigid-flex solution eliminates multiple connectors, cable lengths, and the assembly labor to route and secure cables. Total system volume drops by 30-40% in typical applications. For aerospace applications where FlexPlus provides solutions, this space and weight efficiency directly impacts payload capacity and performance. In consumer products, it enables sleeker industrial design that influences purchasing decisions.

The mechanical advantages matter too. Flexible circuits with well-designed connectors absorb vibration better than rigid boards connected by stiff cables. This improves reliability in mobile applications from automotive to handheld devices. The flexible routing also simplifies assembly by eliminating the cable management steps that slow production and introduce quality variability.

Taking Action: Building Better Products Through Smart Interconnect Choices

The flexible PCB connector decision you make today shapes your product’s trajectory for years to come. Getting it right requires intentional strategy, not afterthought selection from a catalog.

Start by mapping your complete set of requirements following established flexible PCB design rules. Document electrical specifications—voltage, current, signal frequencies, impedance requirements. Define mechanical constraints—mating cycles, bend radius, vibration resistance, temperature range. Identify space limitations and assembly process capabilities. This comprehensive requirements picture ensures you evaluate connectors against real needs rather than assumptions.

Engage your manufacturing partners early. At FlexPlus, we encourage customers to discuss connector strategies during the design phase, not after layouts are complete. Our engineering partnership approach means we can provide DFM analysis that identifies potential issues before they become expensive problems. We’ve helped customers transition from prototype connectors that worked fine for ten units to production-ready solutions that scale to thousands without yield issues.

Test your connector choice under realistic conditions before committing. Build prototypes that undergo the full lifecycle of stresses your product will face. Environmental testing, repeated mating cycles, vibration testing—these validation steps catch problems when fixes are still relatively inexpensive. One customer developing industrial automation systems discovered through testing that their chosen connector’s locking mechanism released under sustained vibration. Catching this during prototyping cost them two weeks and a few thousand dollars. Missing it until production would have cost months and jeopardized customer relationships.

Consider the total solution, not just the connector in isolation. The flexible circuit design and layout techniques affect connector reliability as much as the connector itself. Stress relief features, proper reinforcement around connector attachment points, and appropriate bend radius allowances all contribute to system reliability. FlexPlus provides complete manufacturing control from flexible circuit fabrication through assembly, ensuring these integration details receive proper attention. Unlike brokers who simply source components, we understand how connector selection and flex circuit design interact.

Look beyond initial costs to lifetime value. A premium connector with gold plating and robust mechanical design might cost 50% more than a basic alternative. But if it eliminates field failures that each cost hundreds to address, the business case becomes overwhelming. Medical device manufacturers understand this intuitively—the cost of a device failure far exceeds any component savings. The same logic applies across industries, though the specifics differ. Calculate your risk-adjusted costs, not just bill of materials prices.

The competitive landscape rewards companies that get interconnect decisions right. Your products work reliably. Your assembly yields stay high. Your customer satisfaction scores reflect quality that competitors struggle to match. These advantages compound over time as your reputation for reliability grows.

Whether you’re developing next-generation eVTOL systems, precision medical devices, advanced telecommunications equipment, or cutting-edge consumer electronics, your flexible PCB connector strategy directly impacts your success. The components are small, but their influence is enormous.

At FlexPlus, we’ve spent over twenty years helping customers navigate these decisions. Our combination of certified flexible PCB manufacturing excellence and advanced engineering support means we can guide you through connector selection with the depth of experience that prevents costly mistakes. From initial design consultation through mass production, we’re committed to helping you build products that succeed because the interconnect strategy was right from the start.

Your product deserves more than an afterthought connector choice. It deserves the thoughtful integration of flexible circuits and interconnect solutions that enable reliability, performance, and innovation. The difference between success and failure often comes down to these decisions. Make them count.