The electronics industry stands at a crossroads where miniaturization meets functionality. As devices become smaller yet more powerful, traditional rigid PCB technology struggles to keep pace with demanding design requirements. Enter Pyralux Flex-Rigid Construction—a revolutionary approach that seamlessly combines the flexibility of polyimide circuits with the structural integrity of rigid boards. This technology has transformed how engineers approach complex multi-layer assemblies, enabling innovations that were once considered impossible.

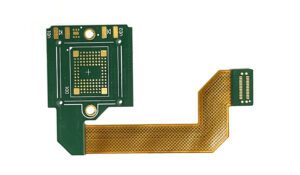

Pyralux Flex-Rigid Construction represents more than just another manufacturing technique. It embodies a fundamental shift in how we think about circuit board design. By integrating flexible and rigid sections within a single assembly, this technology eliminates the need for connectors and cables that traditionally linked separate board components. This design approach prevents common failure modes associated with mechanical interconnections. The result? Lighter, more reliable, and significantly more compact electronic devices that can withstand harsh environments while maintaining peak performance.

The significance of this construction method becomes evident when examining modern electronics. Consider the head-up display in an electric vehicle, where the circuit must wrap around curved surfaces while maintaining signal integrity at high frequencies. Or think about medical implants that require biocompatible materials capable of flexing with body movements without compromising functionality. These applications demand a level of integration that only Pyralux Flex-Rigid Construction can deliver. The technology transitions effortlessly from simple single-layer circuits to complex multi-layer assemblies containing eight or more layers, each precisely engineered to perform specific functions.

What makes this construction method particularly revolutionary is its versatility. Engineers can design circuits that bend in specific areas while remaining rigid in others—perfect for devices where space comes at a premium. The aerospace industry relies on this technology to reduce weight without sacrificing reliability. Consumer electronics manufacturers use it to create sleeker, more elegant products. Medical device companies leverage its biocompatibility for life-critical applications. In each case, Pyralux materials provide the foundation for innovation.

The Material Science Behind Pyralux Excellence

At the heart of Pyralux Flex-Rigid Construction lies a sophisticated understanding of material properties. The Pyralux family of laminates, specifically engineered for flexible and rigid-flex applications, combines polyimide substrates with copper cladding to create circuits that excel in thermal stability, chemical resistance, and mechanical durability. Unlike standard FR-4 materials used in rigid boards, polyimide offers exceptional performance across a wider temperature range—withstanding extremes from -200°C to +260°C without degradation.

The all-polyimide construction of materials like Pyralux AP represents the industry standard for thermal, chemical, and mechanical properties. This double-sided copper clad laminate serves as the foundation for high-reliability circuits in applications where failure simply isn’t an option. The material’s inherent flexibility allows circuits to bend, fold, and flex repeatedly without cracking or losing electrical continuity—a critical requirement for devices subjected to constant movement or vibration.

Layer symmetry plays a crucial role in Pyralux Flex-Rigid Construction. Engineers must carefully balance copper weights and layer thicknesses to prevent warping and stress concentration points. In a typical rigid-flex assembly, the flexible sections contain thinner polyimide layers and lighter copper weights, while rigid sections incorporate thicker materials and heavier copper for enhanced current-carrying capacity and structural support. This symmetrical design ensures the board maintains dimensional stability during manufacturing and throughout its operational lifetime.

Advanced techniques like microvias have revolutionized what’s possible with Pyralux materials. These laser-drilled holes, measuring as small as 75 micrometers in diameter, enable high-density interconnect designs that pack more functionality into less space. When combined with fine-pitch components—parts with leads or pads spaced mere millimeters apart—microvias allow engineers to route complex signal paths without adding unnecessary layers. The result is a more compact, lighter assembly that maintains excellent electrical performance.

The dielectric properties of Pyralux materials deserve special attention. With precisely controlled dielectric constants and dissipation factors, these laminates enable controlled impedance routing essential for high-speed digital signals and RF applications. A head-up display in an electric vehicle, for instance, requires signal integrity at frequencies exceeding several gigahertz. Pyralux materials maintain consistent electrical characteristics across this frequency range, ensuring crisp, clear images without distortion or signal degradation.

Integration Techniques for Complex Assemblies

The process of creating Pyralux Flex-Rigid Construction involves sophisticated integration techniques that blend art with engineering precision. The layering process begins with careful material selection, where engineers choose specific Pyralux laminates based on the application’s thermal, electrical, and mechanical requirements. Each layer serves a distinct purpose—some carry power, others handle high-speed signals, while still others provide ground planes for noise reduction and EMI shielding.

Adhesive application represents a critical step in the integration process. Traditional acrylic adhesives work well for many applications, but high-reliability designs often require adhesiveless constructions using materials like Pyralux HT bonding film. This all-polyimide solution offers superior adhesion and electrical insulation while maintaining the flexibility needed for dynamic applications. The bonding film protects surface circuitry as coverlay material, creating environmental barriers against moisture, chemicals, and mechanical damage.

Controlled impedance routing demands meticulous attention during the design and manufacturing phases. Engineers calculate trace widths, spacing, and layer stackups to achieve precise impedance values—typically 50 ohms for single-ended signals or 100 ohms for differential pairs. These calculations account for the dielectric constant of Pyralux materials, copper thickness after plating, and the distance between signal traces and reference planes. Even minor deviations can cause signal reflections, reducing the effective bandwidth and potentially causing circuit malfunction.

The transition zones between flexible and rigid sections require especially careful engineering. These areas experience concentrated mechanical stress during bending, making them potential failure points if not properly designed. Engineers specify stiffener materials and adhesives that gradually transition from rigid to flexible, distributing stress over a larger area. The Pyralux material system’s inherent toughness helps prevent delamination at these critical interfaces, but proper design remains essential for long-term reliability.

Consumer electronics manufacturers rely heavily on these integration techniques. Smartphone modules, for example, pack cameras, antennas, and processors into spaces measuring just a few cubic centimeters. Pyralux Flex-Rigid Construction enables this density by eliminating bulky connectors and allowing circuits to fold around batteries and other components. The resulting devices are thinner, lighter, and more reliable than designs using traditional interconnection methods.

Automotive systems present unique challenges that Pyralux integration techniques address effectively. Electric vehicle battery management systems must monitor hundreds of individual cells distributed throughout the vehicle’s chassis. Flexible circuits made from Pyralux materials can stretch across multiple meters while maintaining electrical performance and surviving temperature extremes from -40°C in winter conditions to +125°C near motors and power electronics. The lightweight construction reduces vehicle weight, directly improving range—a critical consideration for EV manufacturers.

Medical device applications showcase the biocompatibility advantages of Pyralux materials. Implantable sensors and drug delivery systems require circuits that flex with body movements while maintaining hermetic seals against bodily fluids. The chemical resistance of polyimide prevents degradation from exposure to blood, saline, and other biological materials. Combined with careful encapsulation techniques using biocompatible coatings, Pyralux Flex-Rigid Construction enables life-saving medical innovations that function reliably for years inside the human body.

The Future of Electronic Integration

Understanding Pyralux Flex-Rigid Construction techniques opens doors to next-generation electronic products that push the boundaries of what’s possible. The technology’s ability to handle complex multi-layer assemblies while maintaining flexibility and reliability positions it at the forefront of innovation in emerging fields. Low-altitude airspace applications, including drones and electric vertical takeoff and landing vehicles, demand circuits that withstand vibration, temperature cycling, and electromagnetic interference while minimizing weight. Pyralux materials meet these stringent requirements, enabling the flight control systems and sensor arrays that make autonomous flight possible.

The beauty tech industry has embraced flexible circuits for creating sophisticated devices that conform to human anatomy. Smart beauty gadgets incorporate sensors, heating elements, and wireless charging—all integrated into compact, wearable packages using Pyralux Flex-Rigid Construction. These devices maintain functionality despite repeated bending and exposure to cosmetics and moisture, demonstrating the material’s resilience in consumer applications.

Augmented reality wearables and AI-powered glasses represent another frontier where Pyralux technology shines. These devices pack high-resolution displays, cameras, processors, and wireless communication systems into frames weighing just a few grams. The circuits must flex to fit around curved lenses while routing high-speed video signals without degradation. Traditional rigid circuits with cable connections simply cannot meet these requirements. Pyralux Flex-Rigid Construction, however, enables designers to create elegant, functional AR devices that users can wear comfortably for extended periods.

The aerospace and defense sectors have long recognized the value of flexible circuits, but recent advances in Pyralux materials have expanded possibilities even further. Phased antenna arrays that conform to aircraft surfaces enable advanced radar and communication systems with unprecedented performance. Satellite electronics built using Pyralux laminates survive the intense vibration of launch and the thermal cycling of space while maintaining reliability over mission durations measuring decades.

At Flex Plus (Xiamen) Co., Ltd, we’ve dedicated over twenty years to mastering these integration techniques and pushing the boundaries of what’s possible with Pyralux Flex-Rigid Construction. Our philosophy centers on innovation, certified excellence, and complete manufacturing control. Unlike brokers or trading companies, we maintain our own 8,000+ square meter factory with advanced production lines capable of handling everything from rapid prototyping to high-volume production.

Our certification portfolio—including ISO 9001, ISO 13485, IATF 16949, IPC-6013, and ISO 14001—demonstrates our commitment to quality across multiple industries. For medical device manufacturers, our ISO 13485 certification ensures processes meet stringent regulatory requirements. Automotive customers benefit from IATF 16949 compliance, guaranteeing parts meet automotive quality standards. These certifications aren’t just badges on our website; they represent systematic approaches to quality management that permeate every aspect of our operations.

We’ve developed particular expertise in advanced technologies that complement Pyralux Flex-Rigid Construction. Our flexible substrate COB (Chip-on-Board) technology achieves industry-leading precision, with die bonding offset angles controlled within ±5 degrees—far exceeding typical industry standards. This precision enables ultra-thin modules where chips mount directly onto flexible circuits, eliminating packaging thickness and enabling devices that traditional methods cannot achieve. Our innovative magnetic fixture technology solves the challenge of maintaining flatness on flexible substrates during the COB process, ensuring consistent quality across production runs.

The engineering partnership we offer extends beyond manufacturing. Our team provides comprehensive design support from initial concept through mass production, including DFM (Design for Manufacturing) analysis that identifies potential issues before they become expensive problems. We help customers select appropriate Pyralux materials for their specific applications, balancing electrical performance, mechanical requirements, and cost constraints. This collaborative approach reduces development risk and accelerates time-to-market—critical advantages in fast-moving industries.

Our global customer base spanning North America, Europe, Asia, and beyond trusts us to deliver reliable solutions for their most challenging applications. From precision smartphone modules to industrial automation systems, from optical transceivers to advanced medical devices, Flex Plus provides the expertise and manufacturing capabilities needed to turn innovative concepts into successful products.

As electronic devices continue shrinking while functionality expands, Pyralux Flex-Rigid Construction will play an increasingly central role in product development. The technology’s ability to integrate complex multi-layer circuits into compact, flexible packages addresses fundamental challenges facing designers across industries. Whether enabling autonomous vehicles, advancing medical diagnostics, or powering the next generation of consumer electronics, Pyralux materials and the integration techniques we’ve explored provide the foundation for tomorrow’s innovations.

The revolution in compact electronics isn’t coming—it’s here, built on the sophisticated engineering and material science embodied in Pyralux Flex-Rigid Construction. Those who master these techniques and partner with manufacturers committed to excellence will lead their industries into the future. At Flex Plus, we stand ready to help you navigate this exciting landscape, turning your most ambitious designs into reality with certified quality, innovative solutions, and the manufacturing excellence that comes from two decades of dedicated focus on flexible circuit technology.