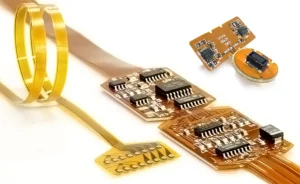

In today’s electronics landscape, the demand for compact, lightweight, and reliable devices continues to accelerate. At the heart of this evolution lies the flex rigid PCB – a revolutionary technology that combines the best of both flexible and rigid circuit boards. These hybrid solutions have become indispensable in industries ranging from automotive and medical to aerospace and telecommunications, offering unprecedented design freedom in three-dimensional spaces.

Understanding the Value of Flex Rigid PCBs

Flex rigid PCBs represent a significant advancement in circuit board technology, featuring alternating layers of flexible and rigid materials. This unique construction delivers remarkable benefits:

– Weight reduction: Critical for aerospace, drone, and portable device applications

– Enhanced reliability: Fewer interconnection points means fewer potential failure sites

– Improved signal integrity: Shorter trace lengths minimize signal degradation

– Three-dimensional design capabilities: Enabling creative solutions for complex spatial challenges

A growing number of innovative applications – from Electric Vertical Takeoff and Landing (eVTOL) vehicles to advanced medical implants – rely on the distinctive advantages that only flex rigid PCB technology can provide.

Essential Capabilities Your Flex Rigid PCB Manufacturer Must Possess

When selecting a flex rigid PCB manufacturer, verifying specific technical capabilities is crucial. The right manufacturing partner should demonstrate excellence in these seven critical areas:

1. Advanced Design Methodologies

A premier flex rigid PCB manufacturer must possess sophisticated design expertise tailored to specific industry requirements:

– Medical-grade solutions: ISO 13485-certified processes for biomedical-compatible devices with ultra-precise tolerances

– Aerospace engineering: Designs that withstand extreme environmental conditions while maintaining signal integrity

Look for manufacturers offering comprehensive design support from concept to mass production, including DFM (Design for Manufacturability) analysis and material consultation. This consultative approach reduces risk and optimizes manufacturing yield – a philosophy embraced by leading manufacturers committed to engineering partnerships rather than simply executing orders.

2. Material Expertise and Selection

The foundation of any quality flex rigid PCB lies in appropriate material selection:

– Flexible areas: Usually polyimide-based materials with varying properties

– Adhesives and bonding technologies: Critical for ensuring reliable layer-to-layer connections

– Specialized substrates: Including TPU circuits for stretchable applications and biocompatible materials for medical devices

Your manufacturer should guide material selection based on operating environment, mechanical requirements, and electrical performance needs rather than simply defaulting to standard options.

3. Manufacturing Precision and Technological Advancement

Today’s high-performance electronics demand exceptional manufacturing precision:

– Layer alignment accuracy: Essential for reliable rigid-to-flex transitions

– Controlled impedance manufacturing: Critical for high-frequency applications

– Advanced via structures: Including blind, buried, and microvia technologies

The manufacturer should utilize state-of-the-art equipment for laser drilling, precision alignment, and automated optical inspection to ensure consistent quality across production runs.

4. Comprehensive Quality Assurance Systems

Rigorous testing protocols are non-negotiable for flex rigid PCB production:

– Flying probe and bed-of-nails testing: Ensuring electrical integrity

– Cross-sectional analysis: Verifying internal structure quality

– Environmental stress testing: Including thermal cycling and humidity exposure

– Bend and flex testing: Confirming mechanical durability of flexible sections

These quality assurance measures prevent potential field failures and ensure the marketability of your electronic products. Without thorough testing, issues like delamination at rigid-flex interfaces, broken traces in flex sections, or compromised impedance control might only surface after product deployment – creating costly recalls and reputation damage.

5. Industry Certifications and Compliance

A reliable flex rigid PCB manufacturer must maintain relevant certifications that validate their processes and quality standards:

– IPC-6013: Specific standard for flexible and rigid-flex printed boards

– ISO 13485: Essential for medical device applications

– IATF 16949: Critical for automotive industry suppliers

– AS9100: Required for aerospace applications

– ISO 14001: Demonstrates environmental responsibility

– UL Certification: Ensures compliance with safety standards

These certifications aren’t just paperwork – they represent adherence to standardized processes that ensure consistent quality and regulatory compliance. When manufacturers follow standards like IPC-6223 specifically for rigid-flex PCBs, they produce circuits capable of withstanding bending, vibration, and thermal stress while maintaining functionality.

For specialized industries like defense or healthcare, additional compliance requirements such as ITAR (International Traffic in Arms Regulations) may apply. Certification to these standards ensures product safety, reliability, and marketability while reducing liability risks.

6. Production Scalability and Flexibility

Your flex rigid PCB manufacturer should demonstrate:

– Capacity for varying volumes: From small specialty runs to high-volume manufacturing

– Consistent quality across production scales: Maintaining tight tolerances regardless of order size

– Flexible lead times: Accommodating emergency requests when necessary

This scalability ensures your product development timeline remains on track while providing flexibility as market demands change.

7. Comprehensive Assembly and Integration Services

The most valuable manufacturing partners offer end-to-end solutions:

– SMT and through-hole assembly: Including mixed-technology boards

– Advanced packaging technologies: Such as flex substrate COB (Chip-on-Board) integration

– Functional testing: Ensuring completed assemblies meet performance requirements

– System integration: Incorporating flex rigid PCBs into complete electronic modules

These turnkey capabilities reduce vendor count, minimize production delays, and maintain consistent quality throughout the manufacturing process.

Selecting the Right Manufacturing Partner

When evaluating potential flex rigid PCB manufacturers, consider these additional factors:

2. Engineering support: Value partners offering design assistance and technical consultation

3. Communication quality: Assess responsiveness, technical understanding, and transparency

4. Innovation focus: Choose manufacturers investing in advanced technologies and processes

5. Global capabilities: Consider geographic reach if you serve international markets

The ideal manufacturing partner combines certified excellence, innovative capabilities, and complete manufacturing control. Unlike brokers or trading companies, direct manufacturers maintain tighter quality control and typically offer more competitive pricing with greater technical support.

Conclusion

Selecting the right flex rigid PCB manufacturer represents a critical decision that impacts product performance, reliability, and time-to-market. By verifying these seven essential capabilities – advanced design methodologies, material expertise, manufacturing precision, quality assurance systems, industry certifications, production scalability, and comprehensive assembly services – you can identify partners capable of supporting your most challenging electronic innovations.

As technologies continue to advance in fields like low-altitude airspace systems, beauty tech gadgets, augmented reality wearables, and medical devices, the importance of working with certified flexible PCB specialists becomes increasingly apparent. The right manufacturing partner doesn’t simply produce boards to specification – they actively contribute to your product’s success through engineering partnership, material optimization, and quality-focused production.

By thoroughly evaluating potential flex rigid PCB manufacturers against these critical capabilities, you’ll position your products for success in increasingly competitive and demanding markets where reliability, miniaturization, and performance cannot be compromised.