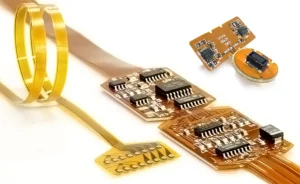

In today’s rapidly evolving electronics landscape, selecting the right flexible PCB materials isn’t just a technical decision—it’s a strategic advantage. As we approach 2025, material innovation is accelerating faster than ever, opening new possibilities for designers and engineers across industries. The materials you choose directly impact your circuit’s flexibility, durability, thermal performance, and electrical characteristics—ultimately determining whether your product succeeds or fails in the market.

From medical wearables that must conform to the human body to electric vehicle components that endure extreme temperatures, the right flexible PCB material makes all the difference. Let’s explore seven game-changing materials that are revolutionizing flexible circuit design and performance for the industries of tomorrow.

1. Polyimide (PI): The High-Performance Champion

When it comes to demanding applications where reliability is non-negotiable, polyimide (PI) remains the gold standard in flexible PCB materials. Its exceptional thermal stability allows it to withstand temperatures up to 400°C without degradation—critical for automotive, aerospace, and industrial applications where heat is a constant challenge.

Beyond temperature resistance, PI offers remarkable chemical resistance, protecting your circuits from harsh environments that would compromise lesser materials. This combination makes polyimide the material of choice for EV battery management systems, where both high temperatures and chemical exposure threaten circuit integrity.

“Polyimide’s molecular structure provides unmatched dimensional stability during thermal cycling,” explains a materials engineer at Flex Plus. “This stability ensures that fine-pitch circuits maintain their precise geometry through countless thermal events, preventing microcracks and connection failures.”

For medical device manufacturers requiring ISO 13485-certified solutions, polyimide offers biocompatibility advantages along with the ability to withstand sterilization processes. Its flexibility—maintaining performance through millions of flex cycles—makes it ideal for devices that must conform to body contours while delivering consistent electrical performance.

2. PET (Polyethylene Terephthalate): Cost-Effective Performance

While polyimide dominates high-performance applications, PET (Polyethylene Terephthalate) delivers an excellent balance of cost and capability for consumer electronics and other moderate-temperature environments.

PET offers several distinct advantages:

– Cost-effectiveness: 40-60% lower material cost than polyimide

– Good electrical insulation properties

– Excellent transparency for applications requiring visual elements

– Respectable chemical resistance for everyday environments

– Suitable for operating temperatures up to 150°C

These properties make PET an ideal choice for consumer wearables, smart home devices, and many smartphone components where extreme conditions aren’t a factor. The material’s natural transparency also enables innovative design approaches in beauty tech and AR wearables, where aesthetics and functionality must seamlessly blend.

“We’ve seen tremendous growth in flexible PET applications for consumer tech,” notes a Flex Plus design consultant. “Its cost advantage allows manufacturers to incorporate flexible circuits in previously rigid designs, creating thinner, lighter products with improved reliability by eliminating connector points.”

For companies seeking rapid prototyping solutions with quick turnaround times, PET-based flexible circuits offer a perfect balance—delivering essential performance characteristics without the lead times sometimes associated with specialized polyimide materials.

3. Paper Phenolic: Surprising Performance in Cost-Sensitive Applications

Though often overlooked in discussions of cutting-edge flexible PCB materials, paper phenolic substrates offer unique advantages for certain applications. This material consists of paper impregnated with phenolic resin, creating a surprisingly capable flexible substrate with excellent dielectric properties.

The most compelling advantages include:

– Extremely cost-effective compared to synthetic polymer options

– Good electrical insulation characteristics

– Environmentally friendly composition with potential biodegradability

– Suitable for single-use medical devices and disposable electronics

– Performs reliably in normal indoor operating conditions

Recent innovations have improved paper phenolic’s moisture resistance and dimensional stability, addressing previous limitations. These advancements make paper phenolic increasingly viable for IoT sensors, RFID applications, and disposable medical devices where environmental impact considerations are gaining importance.

“Paper phenolic represents an often-overlooked sweet spot for certain applications,” explains a sustainability engineer. “We’re seeing growing interest in this material from companies balancing performance needs with environmental goals, particularly for products with planned obsolescence or single-use requirements.”

4. FR-4 Composites: Bridging Rigidity and Flexibility

Traditional FR-4—the standard material for rigid PCBs—has evolved to play a crucial role in flexible circuit design through innovative composites. These hybrid materials strategically combine FR-4’s rigidity with flexible segments, creating circuit boards that offer the best of both worlds.

Modern FR-4 flexible composites provide:

– Robust mounting areas for components requiring stability

– Excellent thermal management in heat-generating sections

– Familiar manufacturing processes that reduce production complexity

– Consistent electrical properties across rigid and flexible sections

– Cost advantages compared to fully flexible designs in certain applications

The advancement of FR-4 composites has been particularly important for rigid-flex PCBs, which are increasingly common in telecommunications equipment, industrial control systems, and aerospace applications. These composites enable sophisticated 3D packaging solutions by combining rigid component mounting areas with flexible interconnection zones.

“The evolution of FR-4 composites represents a significant breakthrough in circuit design flexibility,” notes a Flex Plus engineering specialist. “We’re now able to create complex three-dimensional circuit architectures that conform precisely to product enclosures while maintaining the thermal and structural properties needed for reliable operation.”

5. Teflon (PTFE): Unmatched Electrical Performance in Extreme Conditions

When electrical performance cannot be compromised, Teflon (PTFE) based flexible substrates deliver exceptional capabilities, particularly for high-frequency applications. This material’s unique properties include:

– Extremely low dielectric constant (approximately 2.1)

– Minimal signal loss at high frequencies

– Outstanding chemical resistance to virtually all industrial solvents

– Temperature stability from cryogenic to 260°C

– Excellent hydrophobic properties preventing moisture absorption

These characteristics make PTFE the material of choice for advanced RF/microwave circuits, 5G infrastructure components, and precision test equipment. Its electrical stability across wide frequency ranges ensures signal integrity in applications where data rates continue to increase year after year.

The automotive industry has also embraced PTFE-based flexible circuits for radar modules, lidar systems, and other high-frequency sensing applications critical to advanced driver assistance systems (ADAS). As electric vehicles become more sophisticated, PTFE’s reliable performance in challenging electrical environments becomes increasingly valuable.

“PTFE’s electrical properties remain remarkably stable across temperature and humidity variations,” explains an RF engineer. “This stability is essential for calibrated systems where consistent performance is required regardless of environmental conditions.”

6. Conductive Polymers: Enabling Next-Generation Wearables

Perhaps the most exciting development in flexible PCB materials is the emergence of conductive polymers that fundamentally change what’s possible in circuit design. Unlike traditional circuits that separate conductive and non-conductive elements, these innovative materials integrate conductivity directly into flexible polymer structures.

The advantages are revolutionary:

– Intrinsic flexibility without requiring special manufacturing techniques

– Ability to create stretchable circuits that conform to complex surfaces

– Potential for transparent conductive pathways

– Compatibility with additive manufacturing processes

– Reduced layer count for simpler manufacturing

These properties make conductive polymers ideal for wearable technology, medical monitoring devices, and soft robotics. Imagine a fitness tracker that seamlessly integrates into athletic clothing, or a medical sensor that moves naturally with a patient’s skin without causing irritation.

“Conductive polymers represent a paradigm shift in how we conceptualize circuits,” says a Flex Plus innovation researcher. “Instead of forcing traditional rigid electronic components to bend, we’re creating inherently flexible electronic systems that naturally conform to the shapes we need.”

Early applications are already appearing in beauty tech products, where aesthetic requirements demand invisible electronics, and in augmented reality wearables that must combine complex electronics with comfortable, lightweight designs.

7. Liquid Crystal Polymers (LCPs): Precision Performers

Liquid Crystal Polymers (LCPs) represent the cutting edge in high-performance flexible circuit materials. These specialized polymers offer an exceptional combination of electrical, thermal, and mechanical properties that make them ideal for the most demanding applications.

Key advantages include:

– Extremely low moisture absorption (<0.04%)

– Exceptional dimensional stability for fine-pitch circuits

– Outstanding chemical resistance

– Very low dielectric constant and loss for high-speed signal integrity

– Natural flame retardancy without additives

These properties make LCPs particularly valuable for high-precision telecommunications equipment, aerospace applications, and optical transceiver modules where signal integrity at high frequencies is paramount. The material’s dimensional stability ensures that ultra-fine circuit features maintain their precise geometry through manufacturing processes and in operation.

“LCPs deliver unmatched performance in high-frequency applications where even minor signal losses or impedance variations can compromise system performance,” notes a telecommunications specialist. “As data rates continue increasing, LCP becomes increasingly important for maintaining signal integrity.”

For companies developing cutting-edge products for 5G infrastructure or satellite communications, LCPs provide the perfect combination of electrical performance and mechanical reliability needed to push technological boundaries.

The Critical Role of Material Selection in Your Product’s Success

As we look toward 2025, selecting the right flexible PCB material has never been more important. The material choices you make directly impact not just your product’s performance, but its manufacturability, reliability, cost structure, and ultimate market success.

The complexity of this decision underscores the importance of working with experienced flexible PCB manufacturers who understand both the technical characteristics of these materials and their practical implications for your specific application. An experienced partner can help navigate tradeoffs between performance, cost, and manufacturability to find the optimal solution.

At Flex Plus, we understand that each industry faces unique challenges—whether it’s the extreme reliability demands of EV components, the biocompatibility requirements of medical devices, or the signal integrity needs of telecommunications equipment. Our approach combines certified excellence (ISO 9001, ISO 13485, IATF 16949) with innovative engineering support to ensure that your flexible circuit material selection optimizes performance without compromising manufacturability.

As flexible PCB materials continue evolving, staying ahead of these advancements becomes a competitive advantage. The seven game-changing materials we’ve explored represent not just current best practices, but the foundation for tomorrow’s innovations across industries from low-altitude airspace and AR wearables to precision smartphone modules and advanced medical devices.

The future of flexible circuit performance depends on making informed material choices today. By understanding these seven game-changing materials and their applications, you’re well-positioned to design products that don’t just meet current requirements, but anticipate the demands of tomorrow’s markets.