In today’s rapidly evolving technological landscape, the push for smaller, lighter, and more powerful electronic devices has led to groundbreaking innovations that redefine what’s possible in product design. At the forefront of this revolution stands miniaturized flexible COB (Chip-On-Board) technology – a transformative approach that’s fundamentally changing how we conceptualize electronic systems across numerous industries.

The impact of this 50μm revolution cannot be overstated. From electric vehicles to medical implants, telecommunications infrastructure to aerospace applications, miniaturized flexible COB technology is enabling previously impossible design capabilities while dramatically improving performance metrics. This remarkable advancement represents not just an incremental improvement but a paradigm shift in electronic manufacturing that’s opening new frontiers across the most demanding sectors.

Breaking Barriers with Ultra-Thin COB Technology

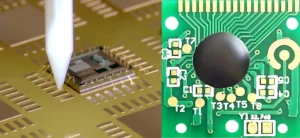

Chip-On-Board technology fundamentally changes the traditional approach to semiconductor integration. Instead of packaging individual chips separately and then mounting them on circuit boards, COB directly attaches bare semiconductor dies to the substrate using wire bonding or flip-chip methods. The critical breakthrough in modern miniaturized flexible COB comes from pushing electronic package profiles below 100 micrometers – with cutting-edge solutions now achieving an astonishing 50μm thickness.

This direct die attachment eliminates bulky packaging, significantly reducing the overall footprint of electronic assemblies while simultaneously improving thermal performance. By removing unnecessary layers and interconnects, miniaturized flexible COB achieves substantially better electrical performance with shorter signal paths and reduced parasitic effects. The elimination of conventional packaging also translates to weight reduction – a crucial factor in applications ranging from wearable technology to aerospace systems.

Unlike traditional Surface-Mounted Device (SMD) packaging, COB technology creates a more compact and robust design with superior reliability characteristics. This is particularly valuable in high-vibration environments like automotive applications or in medical devices where reliability is literally a matter of life and death. The electrical advantages include better signal integrity, reduced noise, and improved high-frequency performance – all critical factors in next-generation electronics.

The achievement of package profiles below 100μm represents a watershed moment for flexible electronics. At this scale, devices can conform to complex three-dimensional surfaces while maintaining full electronic functionality – enabling entirely new product categories and use cases that were previously technologically infeasible.

Materials Science: The Foundation of Miniaturization

The remarkable advances in miniaturized flexible COB technology wouldn’t be possible without corresponding breakthroughs in materials science. The selection of flexible substrates represents a critical engineering challenge, requiring materials that offer an optimal balance of thermal stability, electrical performance, and mechanical flexibility.

Polyimide remains the gold standard substrate for many flexible COB applications, offering exceptional thermal stability (withstanding temperatures up to 400°C) combined with excellent electrical insulation properties. For applications requiring enhanced thermal management, ceramic-filled composites provide superior heat dissipation without sacrificing flexibility. These advanced substrate materials enable the creation of ultra-thin circuits that can withstand thousands of flex cycles while maintaining electrical integrity.

Adhesive systems represent another critical material component, requiring formulations that provide robust die attachment while accommodating the thermal expansion mismatch between silicon and substrate materials. Modern flexible COB implementations utilize specially engineered adhesives with controlled flow characteristics and excellent temperature stability, ensuring reliable performance across demanding environmental conditions.

Encapsulation technologies have similarly evolved to protect the delicate wire bonds or interconnects while maintaining overall flexibility. Advanced dam encapsulation processes now achieve thickness tolerances of ±5μm – an extraordinary level of precision that enables reliable protection while maintaining the ultra-thin profile that defines this technology.

These material advances collectively enable the development of lightweight, efficient designs suitable for applications spanning from wearable technology to aerospace systems. For example, in medical wearables, flexible COB technology allows devices to conform comfortably to the human body while incorporating sophisticated sensing and processing capabilities. Similarly, in aerospace applications, the weight reduction and reliability improvements offered by miniaturized flexible COB translate directly to fuel efficiency and mission-critical performance.

Manufacturing Innovation: Precision at Scale

The production of miniaturized flexible COB requires manufacturing capabilities that push the boundaries of what’s possible in electronic fabrication. Advanced techniques like inkjet printing and roll-to-roll processing have revolutionized how these sophisticated components are manufactured, enabling unprecedented precision and efficiency.

Inkjet printing technology allows for the direct deposition of conductive traces and other circuit elements with microscopic precision. This additive manufacturing approach eliminates waste, reduces processing steps, and enables rapid design iterations – all while maintaining the tight tolerances required for high-performance electronics. The ability to precisely control material deposition at the micron scale is fundamental to achieving the ultra-thin profiles that characterize miniaturized flexible COB technology.

Roll-to-roll processing represents another manufacturing breakthrough, enabling continuous production of flexible circuits at scale. This approach dramatically improves throughput and reduces costs compared to traditional sheet-based processing, making advanced flexible COB technology economically viable for a broader range of applications. The continuous nature of roll-to-roll processing also improves consistency, with sophisticated optical inspection systems ensuring quality control throughout the production run.

Die bonding precision represents a particularly challenging aspect of miniaturized flexible COB manufacturing. Industry leaders now achieve wafer offset angle tolerances controlled within ±5° – far exceeding traditional industry standards. This precision is essential for proper electrical connectivity and overall reliability, particularly as die sizes continue to shrink and interconnect densities increase.

Innovative magnetic fixture technology has solved one of the most persistent challenges in flexible COB manufacturing – the management of uneven flexible substrates. By ensuring consistent planarity during critical processing steps, these fixtures enable reliable die attachment and wire bonding on flexible materials that would otherwise be problematic.

These advanced manufacturing capabilities enable high-density integration and simplified assembly processes, allowing more functionality to be packed into smaller spaces while reducing assembly complexity. The result is a new generation of electronic products that combine sophistication, reliability, and form factors that were previously unattainable.

Overcoming Implementation Challenges

Despite the tremendous potential of miniaturized flexible COB technology, significant challenges must be addressed to fully optimize performance and scalability. Thermal management represents one of the most persistent issues, as the ultra-thin profiles limit traditional cooling approaches while the flexible nature of the substrate complicates the integration of heat dissipation structures.

Researchers are actively developing innovative solutions to these thermal challenges, including embedded microfluidic cooling channels within flexible substrates and advanced thermally conductive materials that maintain flexibility. These approaches show promise for enabling higher power densities in flexible COB implementations while maintaining reliable long-term operation.

Electrical performance optimization presents another area of ongoing development. As device speeds increase and signal integrity requirements become more stringent, controlling impedance and minimizing cross-talk in flexible circuits becomes increasingly challenging. Advanced electromagnetic simulation tools now guide the design process, allowing engineers to predict and mitigate potential issues before physical prototyping begins.

Reliability testing methodologies are similarly evolving to address the unique characteristics of miniaturized flexible COB technology. Traditional test approaches often fail to capture the complex interactions between mechanical flexing and electrical performance, necessitating new test protocols that better reflect real-world usage scenarios. Accelerated life testing under combined mechanical and environmental stress conditions provides valuable insights into long-term reliability, guiding material and process improvements.

Manufacturing yield optimization represents another critical focus area, with advanced process control systems and real-time monitoring enabling continuous improvement in production outcomes. Statistical process control methodologies identify key variables affecting yield, allowing manufacturers to systematically optimize their operations for consistent quality at scale.

These ongoing research and development efforts are progressively addressing the challenges associated with miniaturized flexible COB technology, expanding its applicability across an ever-widening range of industries and applications. As each technical hurdle is overcome, new possibilities emerge for innovative products that leverage the unique capabilities of this transformative technology.

Leading the Flexible Future

The miniaturization of flexible COB technology down to the remarkable 50μm level represents a defining technological achievement – one that’s reshaping entire industries and enabling new product categories that were previously impossible. This breakthrough epitomizes the philosophy that has guided Flex Plus (Xiamen) Co., Ltd since 2004: relentless innovation in flexible circuit technology to enable next-generation electronic products.

As China’s leading certified flexible PCB and COB integration specialist, Flex Plus brings over two decades of expertise in pushing the boundaries of what’s possible in flexible electronics. The company’s unique combination of certified flexible PCB manufacturing excellence and advanced COB integration capabilities places it at the forefront of this technological revolution, offering solutions that extend from concept through prototyping to volume production.

The impact of this technology spans diverse sectors. In medical devices, ultra-thin flexible COB enables implantable devices that conform to anatomical structures while delivering sophisticated therapeutic functions. Electric vehicle manufacturers leverage these advanced circuits to reduce weight and increase reliability in critical systems like LiDAR, HUD displays, and camera modules. In telecommunications, the improved electrical performance and reduced size enable next-generation infrastructure supporting ever-increasing bandwidth demands.

What truly sets advanced flexible COB implementations apart is their systematic approach to miniaturization. Industry leaders achieve COB and encapsulation thickness tolerance controlled within 50-100μm (±25-50μm) through rigorous process control and specialized equipment. This precision enables reliable integration of sophisticated semiconductor functionality into flexible form factors that can adapt to the most demanding installation environments.

The future of electronics is unmistakably flexible, with miniaturized COB technology serving as the foundation for a new generation of products that blend seamlessly into our lives and environments. By eliminating traditional packaging constraints, this revolutionary approach enables designers to reimagine what’s possible – creating electronic systems that can bend, flex, and conform while delivering unprecedented functionality.

As we look toward tomorrow’s innovations in fields ranging from augmented reality to aerospace, from beauty tech to biomedicine, the technological foundation provided by miniaturized flexible COB will continue to enable breakthroughs we can scarcely imagine today. The 50μm revolution isn’t just changing our electronics – it’s changing our world.